Business Sectors

Contents

Register to read more articles.

Sailing into history: ammonia engines to hit the water in 2025

The first oceangoing ships to trial two-stroke, ammonia dual-fuel engines will set sail later this year, setting the table for commercialisation of the engine technology, and potentially broader uptake of the carbon-free fuel

Ships will sail into history this year, piloting the first two-stroke, ammonia dual-fuel engines, while marking a major milestone in shipping’s decades-long journey towards decarbonisation.

Leading European engine designers have been methodically progressing towards commercialising these massive, prime movers that will be the first to use a carbon-free fuel.

In January, both Denmark’s MAN Energy Solutions (MAN ES) and Switzerland’s WinGD took significant steps to prove the viability of their ammonia engine technology at their respective European research centres, setting the stage for the first shipboard installations.

At its Copenhagen research facility, MAN ES said a full-scale version of its two-stroke, slow-speed ME-LGIA (Liquid Gas Injection Ammonia) engine ran at a 100% engine load for the first time during testing.

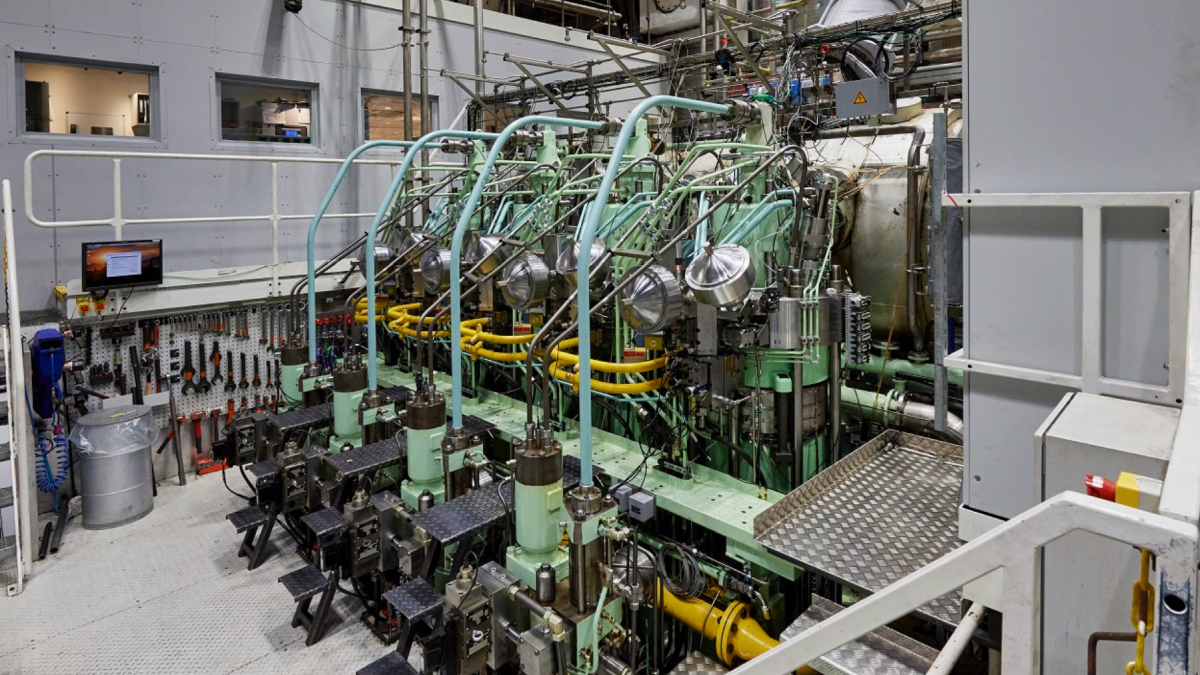

Meanwhile, WinGD said a 52-bore single-cylinder version of its X-DF-A ammonia two-stroke engine is running at the company’s Engine Research and Innovation Centre (ERIC) in Winterthur, with final validation set to allow for the first engine deliveries in June 2025.

Single-cylinder testing allows rapid validation of the ammonia combustion system under engine conditions, as well as optimisation of emissions and performance, said the Swiss engine designer. It follows earlier combustion tests and validation of critical systems on dedicated test rigs and multiple class approvals of the safety concept.

"An ammonia-fuelled ship will require 2.8-3.4 times more space for its fuel”

“The single-cylinder X-DF-A concept is running well, with combustion efficiency, emissions and pilot consumption within our range of expectations,” said WinGD vice president research & development, Sebastian Hensel.

A multi-cylinder engine test at WinGD’s Global Research Centre in Shanghai will validate the full-scale engine, turbocharger configuration and control system before the engine enters production.

Risk mitigation

Progress on releasing the first two-stroke ammonia dual-fuel engine has “proceeded in a cautious and safety-first way,” said MAN ES head of two-stroke research and development, Ole Pyndt Hansen. Since full-scale testing began in November, Mr Hansen said the engine has been operated on ammonia from 25 to 100% load. “As such, we have now validated the ammonia fuel-injection system over the full load curve with diesel-pilot amounts recorded according to our targets,” he said. He added: “Positive emission and performance characteristics from previous, single-cylinder tests have now also been validated in full-scale engine operation.”

Ammonia: zero-carbon, not zero risk

Ammonia, carbon- and sulphur-free fuel, when produced with renewable energy, is seen as a potential alternative fuel for shipping, replacing fossil fuels to allow the sector to drastically lower CO2 and greenhouse gas (GHG) emissions — by as much as 90%. But ammonia, NH3, has vastly different combustion characteristics than traditional marine fuels, is less energy dense and is highly corrosive and toxic, requiring stringent safety protocols. Ammonia’s energy density is 12.7 megajoules per litre (mj/l) at -33° C and 10.6 mj/l in a pressurised tank at 45° C. This compares with an energy density of 35.7 for marine gasoil (MGO). This means an ammonia-fuelled ship will require 2.8-3.4 times more space for its fuel than a ship operating on MGO to travel the same distance. Additionally, combustion of ammonia has the potential to emit nitrogen oxides (NOx) and nitrous oxides (N2O) — a powerful GHG — requiring the use of selective catalytic reduction (SCR).

MAN ES reported its SCR “was operational at all test loads to treat exhaust gases, and that all supply and safety systems worked as intended.” The next steps in the testing will be to focus on performance and emissions optimisation, including injection and SCR systems as well as control strategies.

“The single-cylinder X-DF-A concept is running well”

MAN ES head of global sales and promotion, two-stroke business, Christian Ludwig, noted the inherent design of the ME-LGIA — built on the Diesel-cycle combustion principle — makes it well suited for power takeoff (PTO) applications. “Prior to this round of testing, we simulated PTO on the ammonia engine with very positive results and are very happy to see this replicated in real life. We intend to support PTO on the ME-LGIA to the same degree as with the other Diesel-cycle engines in our low-speed portfolio,” he said.

Using a PTO system can help reduce fuel consumption, lower CO2 emissions and improve a ship’s Energy Efficiency Design Index (EEDI).

Toxic nature

The toxic nature of ammonia has all parties involved in the development of ammonia engine technology proceeding cautiously. One accident with an ammonia release could well setback engine development for years or spell an end to the fuel’s future in the marine sector. That’s why the Danish engine designer has taken a ‘belt and suspenders’ approach when it comes to the engine’s safety. Before it releases the ME-LGIA for commercial sales, MAN ES is undertaking pilot projects in South Korea, China and Japan to collect performance and operational data, and gather insight on crew experience. A company spokesman confirmed that MAN ES was engaged in several pilot projects with shipowners to safeguard the introduction of the marine fuel. “Full sales release of G50, S60, G60, G70 and G80 ME-LGIA will proceed in the market as soon as the vessel or vessels have demonstrated positive seagoing service experience operating on ammonia,” he said.

WinGD head of testing and validation, Sotiris Topaloglou, pointed out that investing time in the early testing phases of ammonia engine development pays off. WinGD began its ammonia engine development six years ago, and in 2022 tested its spray combustion chamber (SCC). This was followed by the testing of key engine components at ERIC’s Future Fuels Lab.

“In previous tests, we verified that SCC results were transferable one-to-one to the results on our test engines,” he said. “As a result, we are in a strong position to make rapid progress through validation of our ammonia technology,” said Mr Topaloglou.

Even before the single-cylinder engine tests started, the X-DF-A ammonia fuel injectors were tested on test rigs to validate the functional, mechanical behaviour and reliability, and on a multi-cylinder methanol engine at 100% load. The later test using methanol allowed WinGD a further opportunity to verify the ammonia injection concept under harsh engine conditions and thermal stress and make improvements before testing with ammonia.

First ammonia engines

WinGD reports it has secured nearly 30 orders for X-DF-A engines for installation in bulk carriers, container ships, tankers and LPG/ammonia carriers. The first engines will be built for four LPG/ammonia carriers owned by Exmar LPG and 10 bulk carriers operated by CMB.Tech.

The first WindGD ammonia engine to be developed is the 52-bore X52DF-A, followed by the 72-bore variant. X-DF-A engines operate according to the Diesel principle in both diesel and ammonia modes, have the same rating field as WNinGD’s existing Diesel engines and will be available with the same cylinder configurations.

Exmar LPG is building six 46,000-m3 LPG/ammonia carriers at HD Hyundai Mipo, the first two of which will have LPG dual-fuel engines, and the last four ammonia dual-fuel engines. The six midsize carriers will fly the French flag and be operated by newly created Exmar LPG France. The first two ships in the series, Champagny and Courchevel, were named in ceremonies in January.

In the case of MAN ES, one of the first engines to be installed will be a 60-bore MAN B&W 7S60ME-LGIA engine with SCR, which is earmarked for a 200,000-dwt bulk carrier being built at Nihon Shipyard for a joint venture of K Line, NS United and Itochu Corp.

MAN ES licensee Mitsui E&S Machinery is building the engine and is responsible for developing the ammonia fuel tank and fuel supply system, while Nihon Shipyard is building the ship equipped with ammonia fuel tanks, ammonia fuel handling system onboard the vessel, and safety systems onboard. ITOCHU Corp, K Line and NS United will be responsible for crew development and ship management and collection of operational data.

A memorandum of understanding, signed in 2024 between MAN ES and its five Japanese partners, laid out the details of the pilot project.

While LNG and methanol have stolen the alternative fuel show up to this point, interest in ammonia is beginning to percolate. Lloyd’s Register, which issued an approval in principle for WinGD’s X-DF-A engine range in 2023, reported 22 ammonia-fuelled vessels were ordered in 2024, more than double the previous year. “In 2025 the first ammonia-fuelled marine engines will be delivered, with a further surge in orders likely as the industry gains experience with the carbon-free fuel,” said the class society.

MAN ES intends to release G50, S60, G60, G70 and G80 ME-LGIA to the market “as soon as the first vessel or vessels have demonstrated positive seagoing service experience operating on ammonia,” said a spokesman for MAN ES. Potential first movers for ammonia engines are expected to be very large ammonia carriers, large bulk carriers and pure car and truck carriers.

Related to this Story

Events

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.