Business Sectors

Contents

Seagems deal adds predictive maintenance to OSVs in Brazil

The offshore support vessel owner has contracted original equipment manufacturer Wärtsilä to analyse real-time data in a bid to minimise downtime

Machinery on offshore support vessels operated by Brazil-headquartered Seagems will be fitted with sensors to enable remote performance monitoring to reduce the risk of downtime.

Seagems, formerly known as Sapura, will use data from propulsion machinery across its fleet for predictive maintenance, in a bid to minimise machinery failures and repairs and avoiding potential operational outages.

Data from the support vessels will be transferred via satellite communications to cloud-based services enabling machinery and vessel performance to be monitored remotely, and to proactively manage maintenance requirements.

Digital real-time information on engines and propulsion systems will enable engineering experts to identify potential issues before they impact vessel operations.

To achieve this, Seagems has extended a lifecycle agreement with Wärtsilä Corp to include digital and analytics services over its OSV fleet of platform supply ships and subsea construction and maintenance support vessels.

“The renewal and expansion of the existing agreement will support our long-term operational goals for these vessels, particularly in enhancing efficiency, reliability and sustainability,” said Seagems chief operating officer Ricardo Bicudo.

Wärtsilä’s data collection and cloud-based services will be used for real-time remote monitoring and to proactively manage engine and propulsion system maintenance. It includes Wärtsilä’s expert insight, a predictive maintenance solution and tailored field services for engines and propulsion systems.

’s nextVessel Optimisation Webinar Weekfocus on AI-driven vessel optimisation, practical decarbonisation strategies, and the integration of digital twinUse this link for more information and to register

Related to this Story

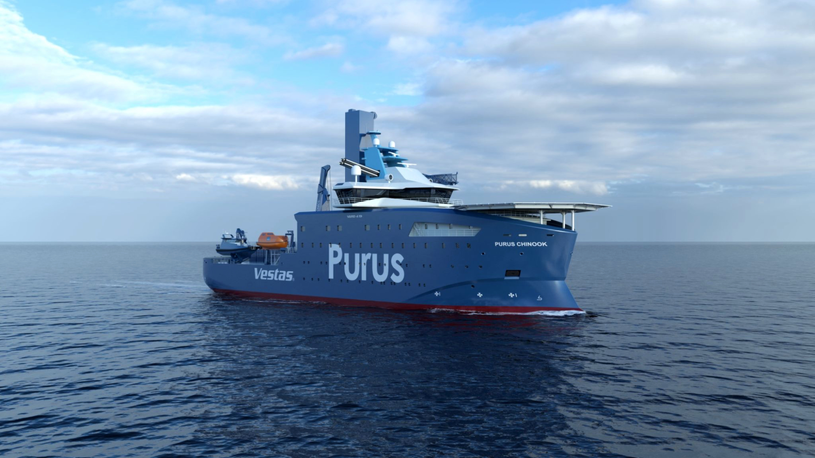

AI, digital twins help design cyber-secure, green SOVs

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.