Business Sectors

Contents

Thrusters ordered for US naval workboats and tugs

US naval workboats and tugs will be propelled by azimuthing thrusters following a series of contract awards from a US shipyard

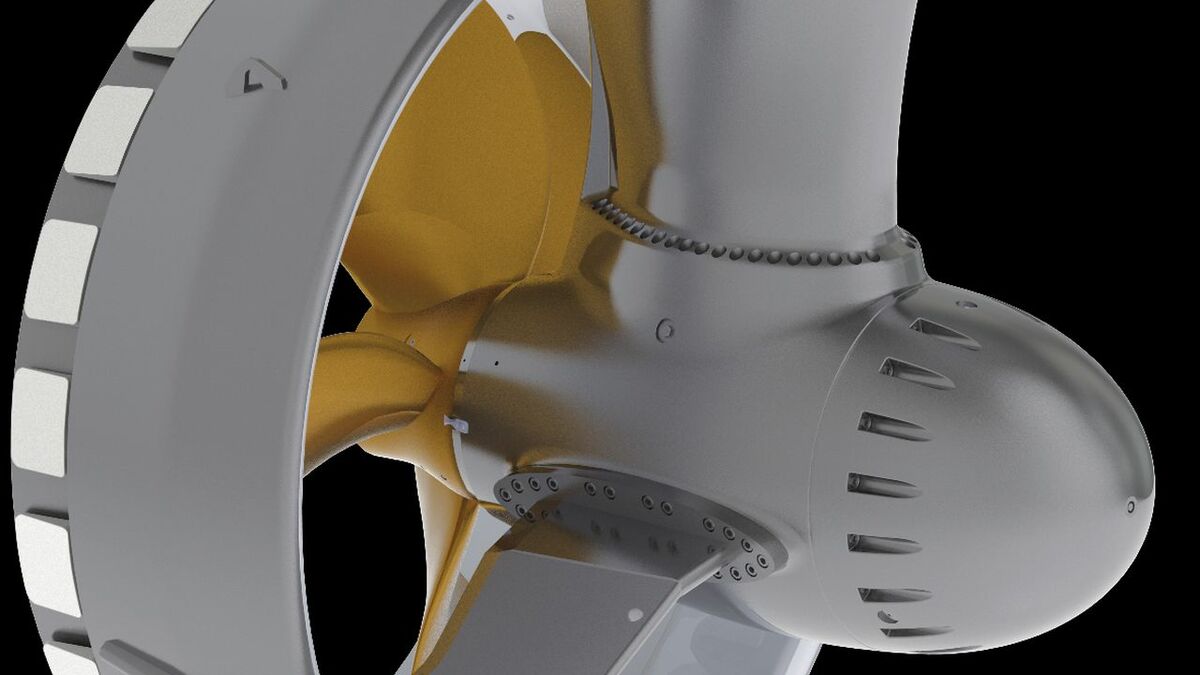

Schottel has won several orders for its Rudderpropellers for harbour tugboats and workboats used for docking US naval vessels.

Modutech Marine Inc is building these over the next three years at its shipyard in Tacoma, Washington state, to support US Navy’s new naval warships as the government modernises its marine assets.

It is building two YTL 815-class tugs using a Robert Allan design and propulsion that complies with US Environmental Protection Agency Tier 4 emissions requirements.

Schottel will supply two Rudderpropellers type SRP 270 FP thrusters for each harbour tug. These will have fixed pitch propellers with diameter of 1.85 m and an input power of 970 kW.

These will be matched to two EPA Tier 4 diesel engines. With this propulsion setup, the tugs are expected to achieve running speeds of around 10 knots and bollard pull of 33 tonnes.

They will have an overall length of 19.2 m, moulded beam of 9.4 m and extensive fendering above and below the waterline to handle US Navy surface ships, submarines and barges. Construction of the lead tug is to commence later this year.

Modutech Marine is building five workboat docking vessels for the US Navy. It has ordered one Schottel SRP 150 azimuthing unit for each vessel, which will have fixed pitch propellers with a diameter of 1.05 m and an input power of 335 kW and be driven by diesel engines.

The Rudderpropellers are equipped with a new nozzle SDC40, which combines compact design and high propulsion efficiency, said Schottel.

- Ice-strengthened thrusters ordered for six-tug newbuilding campaign

- Propulsion ordered for Med Marine escort tug

- OEMs develop integrated propulsion for hybrid tugs

US Navy has previously used Schottel SRPs on its existing YT 802-class harbour tugboats.

Schottel offers its medium-sized thrusters in three sizes. corresponding to common engine power classes. These are SRP 210, with input power of 640 kW, SRP 240 (input power 850 kW) and SRP 270 (input power 1,000 kW).

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.