Business Sectors

Events

Marine Coatings Webinar Week

Contents

Transition in transmission – electric propulsion is changing drivetrains

Electric drivetrains may be the future, but the diesel engine has years to run

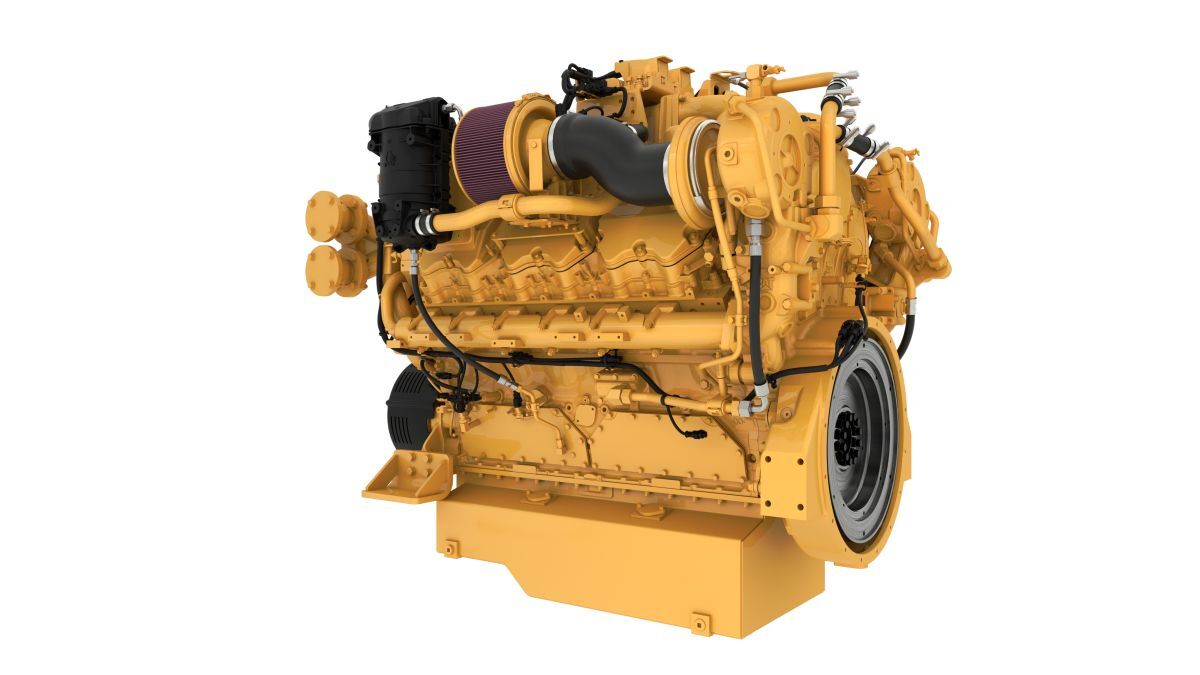

When the Welsh Government’s 19-m long catamaran fisheries patrol vessel, Lady Megan, hit the water earlier this year, it featured a powerful gearbox married to two Caterpillar C18 engines.

Supplied by Marine and Industrial Transmissions (MIT), the four-speed gearbox has to meet tough standards in a vessel that operates year-round in the harsh conditions of the Irish Sea.

Officially classified as MGX 5146 RV, the gearbox features several highly technical elements that make for the robust transmission a vessel with a maximum speed of 27-knots needs. Standard equipment includes a vertically offset aluminium housing, a 10° slant in the output shaft and the properties of the oil strainer and filter.

Highly technical transmission systems such as that on Lady Megan are expected to operate with total reliability, albeit anonymously.

Although the engines attract most of the attention, transmission systems are seeing constant improvements and MIT’s latest product is a case in point. Technically known as a Transfluid Hybrid Module, it is a transmission designed for the future. “The hybrid system can be coupled with a gear within a driveline array to provide the operator with both electric and diesel power,” an MIT spokeswoman told Marine Propulsion.

Accredited by classification society DNV GL in June, the system is the first of its type to be approved within the 100-kW range. And it has also won type-approval for vessels operating at up to 1,100-kW maximum power. Shipowners are taking notice – the system has already been installed on a tugboat and a pilot vessel.

Millimetres

But how does it all work? Nothing if not versatile, the system can be fitted to any combustion-engined vehicle provided it has a standard flywheel and housing, and can be installed between the engine and the transmission in just a few hundred millimetres of space. The electric function doubles up as an electric motor in one mode and as a generator in thermal power mode. The nub of the system is a main rechargeable battery. Thermal power can go up to 1,100-kW and electric power to 300 kW.

In electric mode the vessel sails with zero emissions in complete silence. With the engine running, the device serves as a generator to recharge the batteries. And in ‘booster’ function, the whole package jumps into action to provide extra torque through the driveline.

The future

Hybrid systems are the transmissions of the future. In 2020, MTU will unveil a range of diesel- electric propulsion systems complete with integrated transmissions capable of up to 4,000 kW per power train. They promise to be extremely versatile. “With the aid of a modular system, we will make integrated hybrid propulsion systems available that are tailored to the customer’s specific requirements,” predicts MTU’s head of marine and government business, Knut Muller.

With the transmission married to the diesel engine and electric motor, a hybrid-propelled tugboat will be able to manoeuvre extremely precisely under solely electric power or, by firing up the total package, deliver a powerful bollard pull.

“We will make integrated hybrid propulsion systems available that are tailored to the customer’s specific requirements”

To start with, MTU will offer hybrid systems with its 2000-series engines, combining one or two electric motors per power train, each having 150 kW of electric output. In 2021, MTU will get more ambitious and offer packages including transmission for its 4000 series.

Not to be outdone, Wärtsilä is currently installing one of its hybrid power plants on Acta Centaurus, an X-bowed support vessel for Acta Marine. Transmission systems on these vessels have to maintain a high dynamic positioning load with consequent fluctuating requirements in power. A walk-to-work vessel, Acta Centaurus, will be dedicated to constructing offshore windfarms.

Like much else in the maritime sector, hybrid power plants are a response to the accelerating shift to ‘green’ shipping and retrofits of vessels are on the rise. Wärtsilä is one of several companies taking the lead in a wide variety of global initiatives including zero-emissions shipping that will eventually lead to hybrid systems’ installation. Wärtsilä, for instance, is retrofitting hybrid packages for shortsea shipping vessels.

Not dead yet

Contrary to the opinion of some, diesel engines are far from dead in the maritime industry.

Although electrically powered vessels require adapted transmission systems, transmission manufacturers are still refining their products for diesel-fuelled engines, most of which will be operating for the next 20-30 years if previous performance is anything to go by.

Finland gearbox specialist Katsa is one company that keeps on coming up with innovations that will make diesel engines relevant for longer. One of its latest developments is an integrated pump drive product, a plug-and-play system angled towards fast-running diesels. An all-in-one package, the system comes ready assembled and tested with an internal hydraulic system.

And as Cummins’ executive director of product management and market innovation, Tim Proctor, said in July, “While Cummins has a vigorous electrification programme underway, our other key message is that the diesel engine is not standing still.”

Indeed, on the 100th anniversary of the American manufacturer, Cummins sees itself prolonging the life of the diesel engine for years to come. True to its mission, in September Cummins unveiled a Tier 3-compliant engine package, complete with transmission, known as QSK60 that is suitable, the company says, for marine applications “from commercial work vessels to luxury yachts.”

The first of Cummins’ engine platforms with IMO Tier 3 certification, the package comes with after-treatment technology in the shape of selective catalytic reduction that has been proven on road vehicles for almost a decade. A Vanadia-based catalyst that can be operated with 32.5% or 40% concentrations of diesel exhaust fluid, the after-treatment system more than fulfils the toughest compliance regulations. Even better, it can be paused, says Cummins. That is, switched off once the vessel leaves a zero-emissions zone.

Typically, manufacturers try power plants out on land before installing them in ships. And in May, Cummins and Allison Transmission Systems, one of the biggest manufacturers of fully automatic transmissions for commercial vehicles, won official approval in California for their 2019 diesel-electric propulsion system first developed in 2014.

So far the package has been confined to buses but the technology will likely soon be seen in ships’ enginerooms, as happened with Cummins’ X15 engine that debuted on land before being released for the marine sector.

The next big thing on the block? Probably transmissions for hydrogen cell-fuelled vessels, but that is a few years ahead.

Riviera Maritime Media’s Maritime Hybrid & Electric Conference will examine how vessels can reduce fuel consumption, maintenance costs and emissions.

4-5 September 2019, Bergen, Norway. Tickets can be booked online with a discount for group bookings.

Related to this Story

Events

Marine Coatings Webinar Week

Maritime Environmental Protection Webinar Week

Ship Recycling Webinar Week

© 2024 Riviera Maritime Media Ltd.