Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

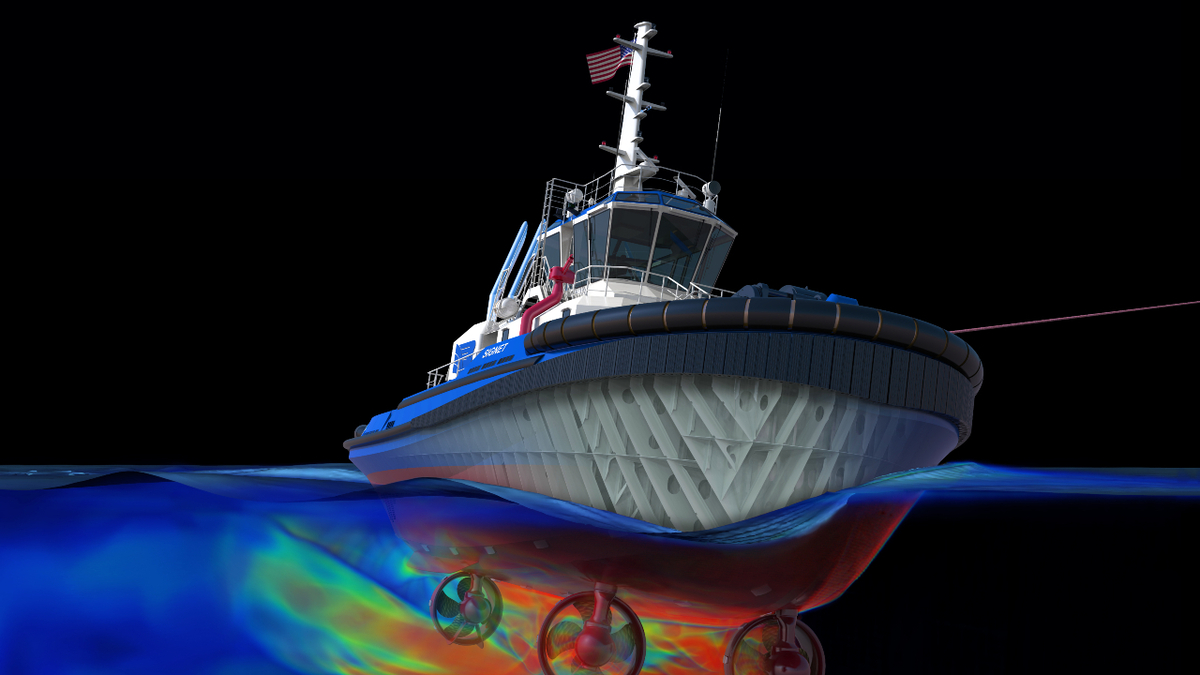

US first: 3D process delivers commercial vessel

In a regional first, ABS, Robert Allan Ltd and Signet Maritime used 3D modelling to design and certify an escort and offshore tug ready for construction in the US

Using 3D processing, a Robert Allan Ltd (RAL) Advanced Rotortug (ART) design was used for the tug which will receive its certificate of inspection from the US Coast Guard (USCG) and will be built and operated by Signet to ABS class.

The first commercial vessel in US history to be produced using only 3D models in design and construction for all structures, the paperless process reduces time and costs in the design, certification and construction processes, streamlining stakeholder interactions without compromising safety.

“The understanding and fidelity of this construction model represents a major milestone in the history of the US maritime industry,” said Signet vice president for engineering and dynamics Timothy McCallum.

“3D design review ensures the designer, engineer, production manager, fitter, welder, and surveyor all work from the same complete model,” he said.

“Each individual has access to both the micro (component) and macro (complete assembly) with which they are working to better understand the bracket, frame, or bulkhead as it relates to the module, section, and ship.”

ABS worked closely with RAL on the review and approval processes of the 3D structural models on this project.

RAL chief executive Mike Fitzpatrick said these processes sped up the design, engineering and construction phases. “Not only has it become easier to exchange complex structural design information this way,” he said, “but the time from the basic design stage to the production design stage is shortened, allowing the shipyard to start cutting steel earlier.”

Project partners said this level of participation in paperless processes will lead to a superior finished product and contribute to safer waterways through technological advancement.

“This landmark achievement sets the bar for future projects both in the US and internationally,” said ABS chairman, president and chief executive Christopher Wiernicki.

“We have realised a long-held dream of the industry to leave behind 2D paper plans and move to the next generation of vessel production. The advantages are significant,” said Mr Wiernicki, “and we are confident that once the industry develops the infrastructure to handle 3D models in shipyards, a pure 3D process will become the default approach.”

Naval architects are increasingly developing ship structures using 3D modelling software. In most projects they produce traditional 2D drawings for class and shipyards but they could provide direct 3D designs to streamline the transition to production design modelling for the shipyard.

“This gives us as naval architects earlier estimates of weights and centres, steel quantities as well as the means to check for structural interferences,” said Mr Fitzpatrick.

This milestone is the latest in a succession of ABS firsts in 3D model-based class. ABS was the first to develop a process for ingesting 3D models into class software to allow 3D model-based reviews in 2018.

ABS then became the first classification organisation to accept 3D models for class surveys in April 2020.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.