Business Sectors

Events

Offshore Support Journal Conference, Middle East 2025

Contents

Register to read more articles.

Ballast water compliance: advances amid technical and regulatory challenges

The MEPC 81 session has advanced ballast water management, addressing challenging water quality, regulatory revisions, and industrywide technical hurdles

IMO’s Ballast Water Management (BWM) Convention, which entered into force in 2017, aims to prevent the spread of harmful aquatic organisms from one region to another. This convention mandates that all ships must implement ballast water management practices to meet specific discharge standards.

The BWM Convention is currently in the Convention Review Stage, part of the broader Experience Building Phase. This phase is critical for assessing how effectively the convention’s provisions are being implemented and identifying areas for improvement.

As part of this process, the IMO Marine Environment Protection Committee (MEPC) holds regular sessions to discuss and refine these guidelines. The last meeting, MEPC 81, was held in March 2024, and was particularly significant for its focus on standardising ballast water compliance and addressing pressing technical and regulatory challenges.

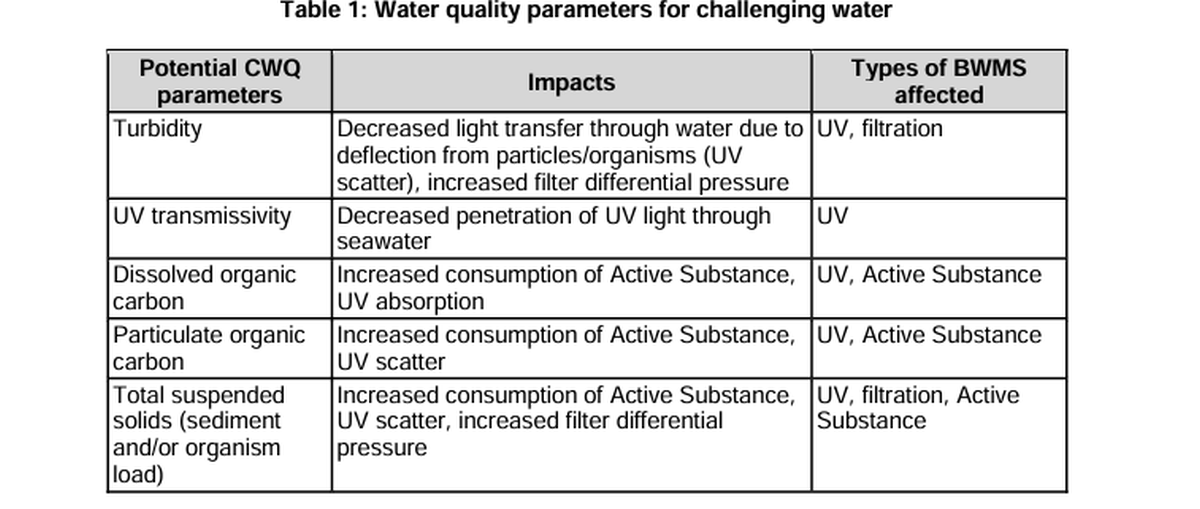

One of the key takeaways from MEPC 81 was the introduction of interim guidance for ships operating in ports with challenging water quality. This guidance is crucial for ensuring that vessels can maintain compliance even in adverse conditions. INTERTANKO regional manager for Southeast Asia and environment manager Elfian Harun, highlighted the importance of this development during a webinar*. "We recognise that for this convention, the expectation in August (2023) was very high, but technology is being improved," he said. The interim guidance advises ships to update their BWM plans to include procedures for dealing with challenging water quality. It also emphasises the need to use ballast water management systems (BWMS), when necessary, to conduct ballast water exchange and treatment.

“Co-operation and trust are essential to make sure everyone contributes to the success of the convention”

A critical tool in this effort is the Ports with Challenging Water Quality (PCWQ) database, developed by INTERTANKO. This database serves as a reference for shipowners and operators, providing data on water quality conditions at various ports. Mr Harun explained that the database aims to "help both the ship and administration to tackle this issue," offering practical insights and facilitating pre-planning to ensure compliance.

MEPC 81 also addressed the issue of temporary storage of treated sewage and grey water in ballast water tanks. Given the operational constraints at some ports, where the discharge of treated sewage is prohibited, ships often need to temporarily store these effluents. However, this practice poses significant risks to BWMS, which are not designed to handle sewage or grey water. The committee introduced new guidelines outlining procedures for transitioning from storage mode back to normal ballast operations.

Another significant focus of MEPC 81 was the challenges faced by ships on short voyages where ballast water exchange or treatment (BWE/T) is not feasible. To address these challenges, the committee proposed revisions to the 2017 Guidelines for risk assessment under regulation A-4 of the BWM Convention. These revisions aim to extend the scope of BWM.2/Circ.63 to include ships operating in shared water bodies where compliance with ballast water exchange is impractical. Mr Harun stressed the need for a pragmatic approach, stating: "We need the system to be able to meet the discharge standard in all situations on a global basis."

The Same Risk Area (SRA) concept was also discussed as a potential interim solution for ships operating in regions where BWE/T is not possible. This concept encourages IMO Member States to collaborate and establish SRAs, which would allow for co-ordinated management of ballast water in shared water bodies. However, the implementation of SRAs has proven challenging, with only one SRA established since 2017. Mr Harun noted that establishing SRAs requires significant scientific analysis and co-ordination between administrations, making it a complex and time-consuming process.

Compliance assessments

MEPC 81 highlighted several technical and regulatory challenges that need to be addressed to improve ballast water compliance. One such challenge is the need to revise type approval procedures for BWMS. The current procedures often fail to account for real-world operational conditions, leading to sub-optimal performance of approved systems. Mr Harun pointed out the necessity for standardised sampling procedures and adherence to IMO G2 Guidelines to ensure consistent and reliable compliance assessments. He also stressed the importance of policy considerations for handling sub-optimal D-2 approved systems and the potential revocation of certification if systems fail to meet discharge standards.

The standardisation of Port State Control (PSC) sampling procedures was another critical issue discussed and to address this, the committee underlined the need for a harmonised approach to PSC sampling, ensuring that all procedures align with IMO guidelines. This standardisation is vital for maintaining fairness and transparency in compliance enforcement.

Technological limitations also pose significant challenges for BWMS, particularly in ports with varying water conditions. Mouawad Consulting CEO, Jad Mouawad, explained that "varying environmental conditions [and] lack of comprehensive real-world performance data" are major hurdles in developing effective BWMS. He stressed the importance of continuous innovation and improvement in BWMS technology to meet these challenges. Mr Mouawad also highlighted the role of feedback mechanisms in this process, stating that "ongoing feedback and data collection from the field are crucial for driving technological advancements and ensuring systems are effective under diverse conditions."

From an industry perspective, shipowners face numerous operational challenges in complying with BWM regulations. The financial burden of installing and maintaining BWMS, coupled with the need to balance compliance with operational costs, places significant strain on shipowners. Mr Harun underscored that the industry must work together to find practical solutions, noting that "co-operation and trust are essential to make sure everyone contributes to the success of the convention."

Manufacturers also play a critical role in the ongoing development and improvement of BWMS technology. Continuous research and development is necessary to address the limitations of current systems and ensure they can perform effectively under real-world conditions. Mr Mouawad underscored the importance of innovation, stating: “The key to improving how this convention works is the development and investment into better technologies.”

Looking ahead, MEPC 82 and subsequent sessions will continue to focus on refining ballast water management practices and addressing unresolved issues. Future sessions are expected to prioritise the standardisation of PSC sampling procedures, revisions to the type approval processes, and the development of new guidelines to address emerging challenges. The ongoing collaboration between regulators, industry stakeholders and technical experts will be crucial in achieving these objectives.

As Mr Mouawad appropriately put it: "We will never develop a machine that can treat all water types, but we can improve our systems and procedures to better meet the standards and protect our marine environments."

* INTERTANKO regional manager SE Asia and environment manager Elfian Harun, and Mouawad Consulting CEO Jad Mouawad, were taking part in Riviera’s Standardising ballast water compliance: key takeaways from MEPC 81 webinar, which took place on 11 April 2024.

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

Maritime Decarbonization Conference, Americas 2026

Offshore Wind Journal Conference 2026

© 2024 Riviera Maritime Media Ltd.