Business Sectors

Events

Contents

DP-optimised propulsors enhance SOV operability

Next-generation thrusters keep offshore service ships in place

New-generation propulsors are enhancing the operational capability of next-generation service operation vessels, as recent contracts attest, including deals awarded to Kongsberg Maritime and Schottel.

In February 2025, Armon Shipyard contracted Kongsberg Maritime to supply a comprehensive propulsion, control and dynamic positioning (DP) package for Bibby Marine’s all-electric commissioning service operations vessel (eCSOV). Under the contract, the company will supply full-electric rim-drive propulsion with azimuth and tunnel thrusters, as well as the automation system, full electrical control system, DP and thruster control.

Kongsberg Maritime says the vessel will benefit from its rim drive thrusters, which incorporate permanent magnet motor technology to enhance energy efficiency and reduce operational costs. “Their compact inboard footprint saves valuable space on board, while their low noise and vibration levels minimise hydroacoustic noise, protecting marine life and improving onboard comfort. Additionally, these thrusters contribute to decarbonisation efforts with their low environmental footprint and use of environmentally approved lubricants.” Bibby Marine newbuild project manager Gavin Forward says the rim drive thrusters “will ensure optimal efficiency and operational excellence.”

The first-of-its-kind eCSOV will be capable of zero-emissions operation and is designed with the largest battery installation to date on an offshore vessel, with a capacity of 25 MWh. Designed to operate solely on electricity, the as-yet-unnamed eCSOV will be equipped with Wärtsilä methanol dual-fuel engines running solely for charging, optimising efficiency, extending battery life, and reducing emissions. A DC grid setup will minimise energy losses, and offshore charging systems will allow simultaneous battery charging and DP.

In July 2025, Schottel reported French owner Louis Dreyfus Armateurs (LDA) had selected the company to supply RudderPropellers Dynamic (SRP-D) for two service operation vessels (SOVs) due to work for Vattenfall. The new vessels are designed Salt Ship Design in Norway and will be built at Shanghai Zhenhua Heavy Industries Co Ltd.

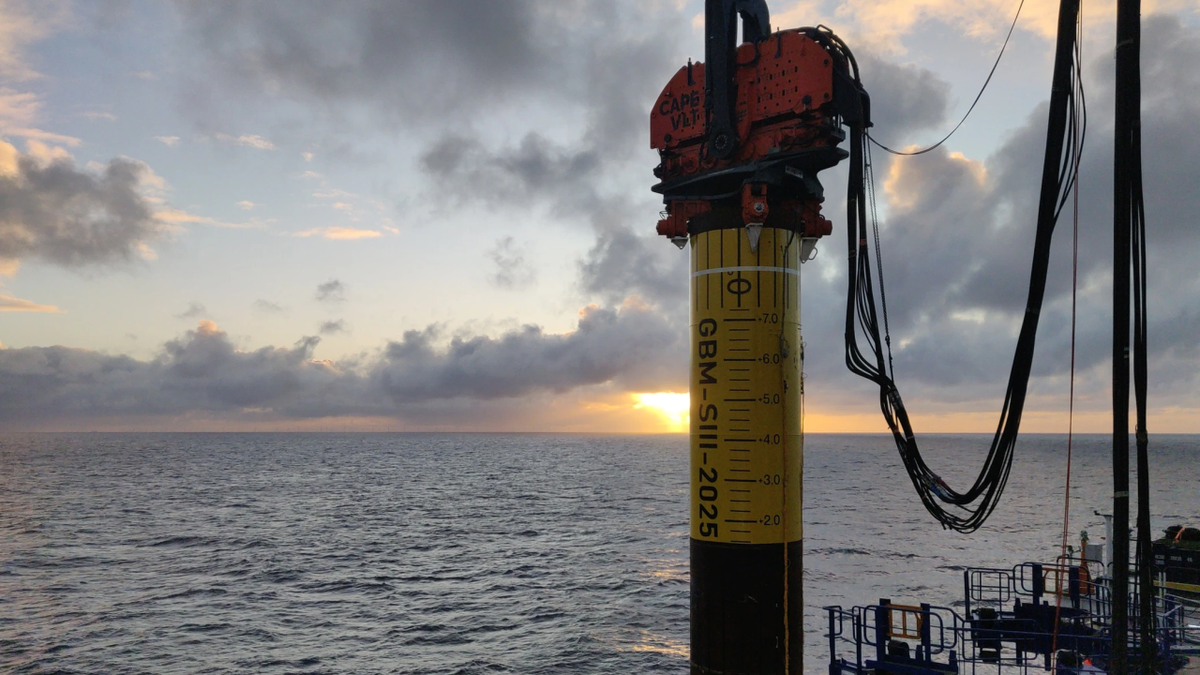

LDA head of engineering Arthur Barret says, “After a thorough evaluation of the available thruster options, we selected a configuration based on four SRP-D rudderpropellers. “This setup ensures optimal dynamic positioning performance, which is key to maintaining maximum operability.” Each SOV will be equipped with four 1,660 kW Type SRP 430 D SRP-Ds.

The SRP-D is marked by improved propeller acceleration/deceleration times and a high-speed azimuth steering system with reinforced gear components, which, says Schottel, enables faster thrust allocation than conventional rudder propellers. “Thanks to the shorter response times, it is possible to react faster and in a more targeted manner to external forces such as wind and currents, thus achieving a higher positioning accuracy,” says Schottel.

The SRP-D is also characterised by a compact design with a vertically integrated electric drive motor and an 8° inclined propeller shaft, which results in less thruster-thruster and thruster-hull interaction and therefore lower thrust losses. The SRP-D was specifically developed for offshore applications, such as those undertaken by SOVs. Apart from enhanced performance and an improved operational capability, the optimised thrust from the SRP-Ds is expected to result in fuel savings.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.