Business Sectors

Events

Offshore Support Journal Conference, Middle East 2025

Contents

Register to read more articles.

Industry workshop aims to reduce loss of containers at sea

How a joint industry project aims to lower the probability of losing containers at sea

Past container incidents in heavy weather throughout the last years have indicated the cargo on board a vessel and its lashing can be crucial to safer cargo transport in challenging climate conditions.

But how to balance efficiency, time constraints and vessel safety while loading a ship in port?

Kaleris has terminals, ocean carriers and ship owners as customers of its Navis brand and is therefore in a good place to gather qualified input and expertise from operations staff about everyday challenges in ship-to-shore operations and to find solutions for existing pain points.

MARIN has organised a joint industry project called ‘TopTier’ which aims to lower the probability of losing containers at sea. Among the work streams investigated in the TopTier project is one focusing on shore-to-ship operations. Initial Top Tier surveys on board container vessels and feedback from vessel crews have indicated concerns for safety at sea arising from the difference between the actual stow on deck and the final stow plan on file, and around the conditions of lashing gear and containers.

Together, both companies recently cohosted a workshop in Rotterdam with terminals, ship operators and shipowners to exchange feedback, opinions and ideas to improve this situation. The discussions centered around why the final stowage plan deviates from the actual deck stow and what that means during loading, discharging and sailing.

Another topic was how to get a valid impression of the actual condition and variations of lashing gear across ships and who should be responsible for regular checks.

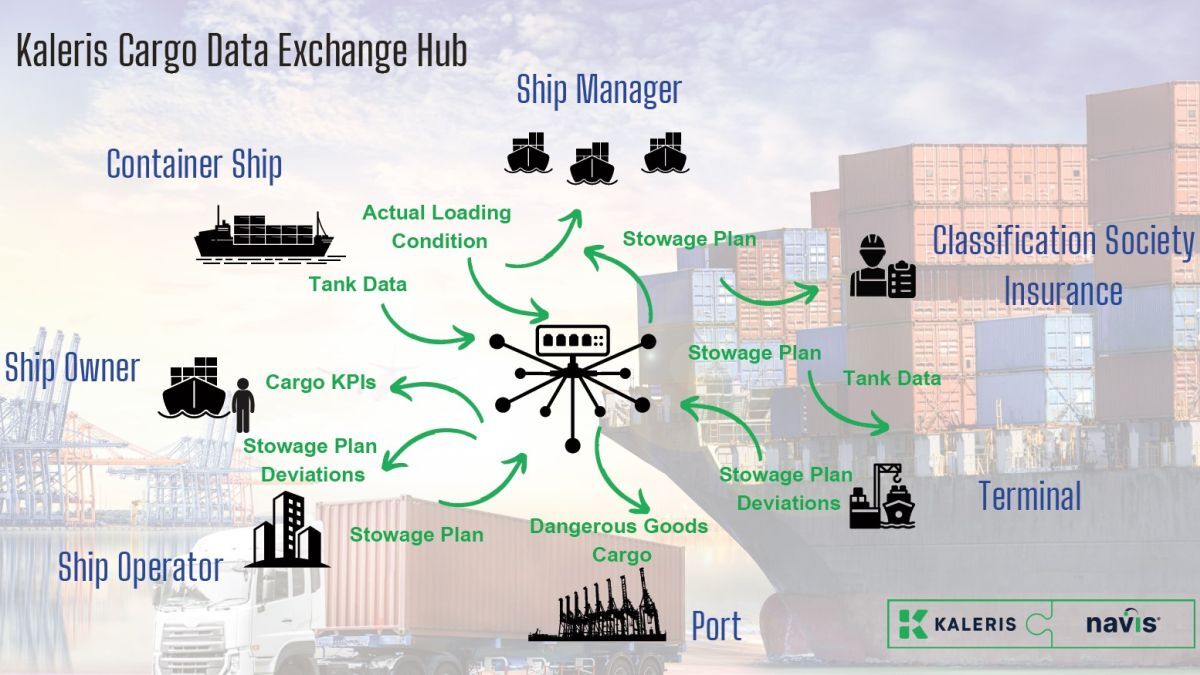

Kaleris introduced its solution of a connected cargo ecosystem in which all stakeholders share data. This would include the departure condition of the vessel, the latest stowage plan and deviations from it, tank data, dangerous goods information and certain cargo KPIs to improve the situation of latest information shared, which mostly relies on email exchange or phone calls.

Kaleris’ solution centres around a cargo data exchange hub, where data from the vessel’s loading computer, the latest plans, cargo bookings from the onshore stowage planning system, and stowage plans from the terminal covering the cargo at the terminal to be loaded or discharged can be seen by everyone who needs to have this information. Deviations from the original loading plan can hardly be prevented, but information about these deviations is crucial to the ship’s crew to determine whether they can sail their vessel safely or not.

As Kaleris provides loading computer systems, stowage planning systems and terminal operating systems, all data sources are already available and just need to be combined to make ship-to-shore operations in ports safer, while maintaining efficiency.

Sign up for Riviera’s series of technical and operational webinars and conferences in 2023:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

Maritime Decarbonization Conference, Americas 2026

Offshore Wind Journal Conference 2026

© 2024 Riviera Maritime Media Ltd.