Business Sectors

Events

Offshore Support Journal Conference, Middle East 2025

Contents

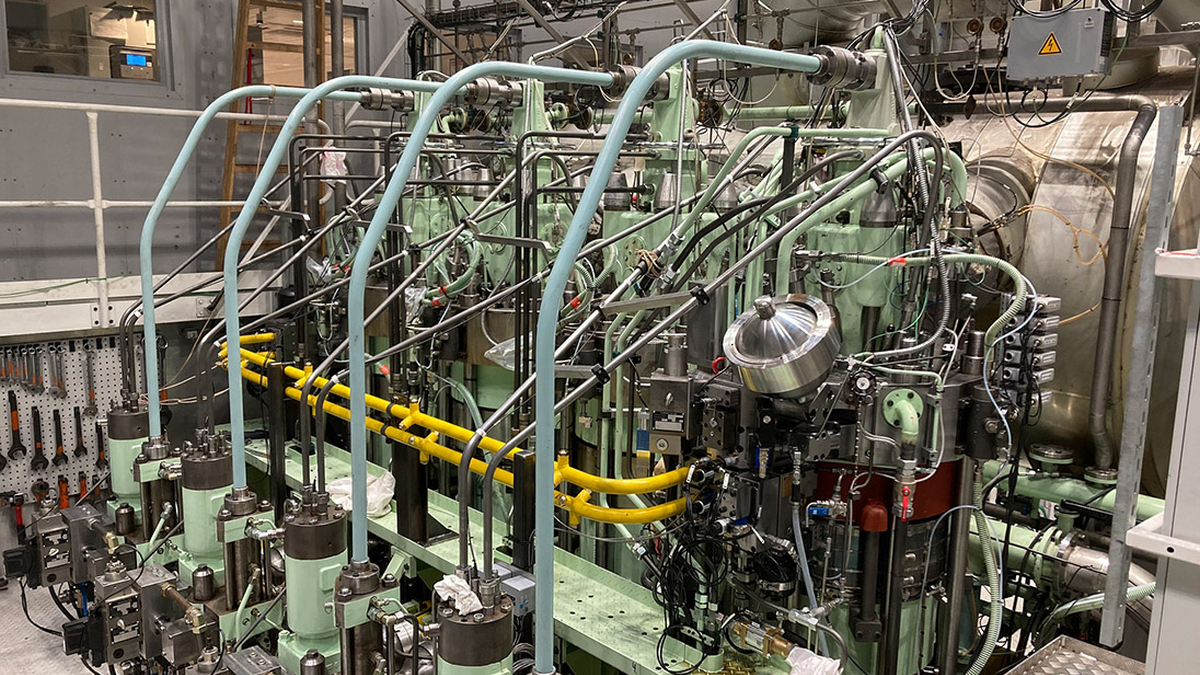

MAN B&W two-stroke engine successfully burns ammonia in first test

MAN’s B&W two-stroke 4T50ME-X type engine was the test bed for the company’s first ammonia engine test that "produced positive results with particularly promising data regarding pilot-oil amount and combustion stability," the company said

MAN Energy Solutions (MAN ES) said the successful first running of a test engine on ammonia took place at its Research Centre Copenhagen (RCC).

MAN Energy Solutions chief technical officer Gunnar Stiesch said, “This marks a major milestone on our road to developing a full-scale two-stroke ammonia marine engine. It’s been a historic week for our team at the RCC where a lot of groundwork and research has now paid off and we have gained a deep understanding of ammonia’s unique characteristics as a marine fuel, as well as its effects on fuel supply and safety systems. This successful combustion represents yet another important step towards decarbonising the marine market.”

The fuel’s inherently toxic characteristics demanded safety precautions for the test that included the construction of a custom-built cold hall that can contain ammonia vapour by activating a water screen in the unlikely event of a leak. Robust safety features from the company’s existing dual-fuel portfolio, such as double-walled piping and system ventilation, have also been built into the ammonia engine’s design.

“This is groundbreaking for both our company and the maritime industry as a whole. That said, we know we still have a lot of hard work ahead and, over the following months, will execute a testing programme that will study aspects such as heat-release, ignition, safety, pilot-oil energy fraction, NOx and N2O emissions. We then plan on rebuilding the test engine from one cylinder capable of running on ammonia to a full-scale test engine running on ammonia around the end of this year or early in 2024,” MAN ES head of two-stroke research and development Brian Østergaard Sørensen said.

The company said it "broadly expects to hold" to the original delivery schedule for completing its first ammonia engine, with operation on board a commercial vessel targeted "from around 2026".

The ammonia engine R&D project started in 2019 with a prestudy and investigation of ammonia combustibility. The following year, a second test engine arrived in Copenhagen, enabling a parallel-test engine setup with different fuels at RCC; HAZID workshops on the engine concepts were performed simultaneously.

In 2021, the ammonia fuel-supply system and auxiliary systems were specified with the highest possible focus on safety, while 2022 saw the installation of the same systems at RCC with instrumentation for test engine No. 1 for one-cylinder ammonia testing initiated.

In 2023, ammonia bunkering and service-tank facilities were built with all auxiliary systems enabling a full containment of ammonia in the unlikely event of a leak. Similarly, all auxiliary systems were initially tested with water, followed by ammonia.

Strategies for reducing GHG emissions from now to 2050. Riviera’s two-day Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2023 conference returns to Amsterdam on 26-27 September 2023, seeking to bring clarity to regulatory directions and decarbonisation pathways for both newbuilds and existing vessels.

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

Maritime Decarbonization Conference, Americas 2026

Offshore Wind Journal Conference 2026

© 2024 Riviera Maritime Media Ltd.