Business Sectors

Events

Offshore Wind Webinar Week

Contents

All-electric thrusters for greener shipping

To meet the demands of fully electric and hybrid propulsion, manufacturers are developing podded, transverse and azimuthing thrusters with permanent magnet motors

An increasing use of energy storage devices and diesel-electric propulsion is ramping up demand for rudderpropellers and nozzled systems.

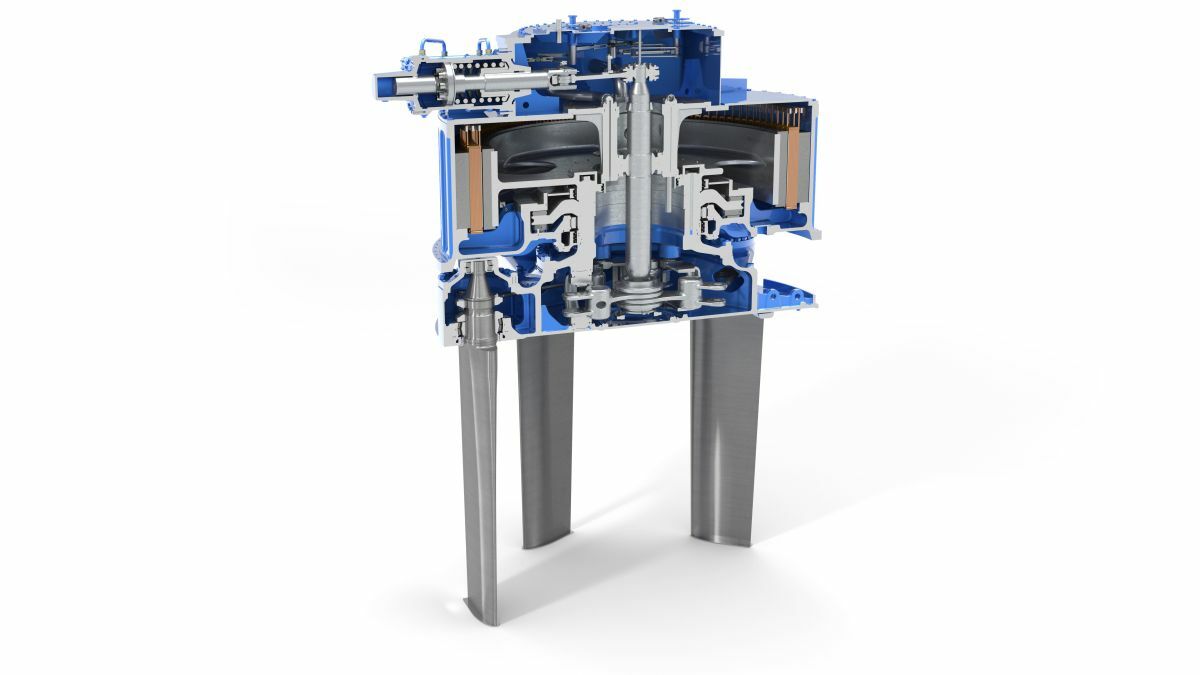

With this in mind, manufacturers are introducing new thrusters with varying power ranges and propeller sizes. In July, Schottel unveiled a new medium-sized azimuth thruster. Its

M-series consists of several rudderpropeller sizes covering a power range of 400 to 1,000-kW.

Schottel is aiming to meet new standards and engine power classes and updated ice-class rules for an increasing number of electric or hybrid-driven vessels.

Initially, M-series will be available in three sizes: 210 (640 kW), 240 (850 kW) and 270 (1,000 kW), corresponding to common engine power classes. All sizes are equipped with a planetary steering gear.

Its azimuth modules are available for Z-drives, L-drives and ZY-hybrid drives, making the thrusters suitable for horizontal electric, vertical electric or combined direct engine plus horizontal electric motor connection and compatible with hybrid systems.

Schottel is offering a standard installation with a variable propeller arm length and a compact minimised variant with a shorter propeller arm length. Its compact installation variants (LC for L-drives, ZC for Z-drives) provide greater design freedom for ship designers.

Part of this series is a development that enables two thrusters to be driven by one engine in a hybrid system. “With Sydrive M, the other engine can then either be idling or used to drive a fire-fighting (FiFi) pump,” says Schottel vice president of sales Roland Schwandt.

“This results in reduced engine running hours, less fuel consumption and, consequently, lowers emissions,” he says.

Sydrive M takes up considerably less space than a hybrid system with an electric motor. This enables vessel operators to minimise running costs when their assets are idle or require less power during slow-speed transits. “More operators rely on integrated slipping clutches to control the propeller at low input speeds or even enable them to drive the propeller and FiFi pump at the same time,” says Mr Schwandt. “This integrated technology, in particular, serves to meet the requirement of a compact system on a vessel where machinery space is limited.”

Schottel has also achieved high efficiency with a high torque gear (HTG) version to maximise bollard pull at minimum power. “The HTG is able to transmit up to 15% more torque without enlarging the diameter of the gear,” says Mr Schwandt.

A further improvement of propulsion efficiency has been achieved by the high-efficiency nozzle SDV45 with the patented Schottel ProAnode system. “This has higher nozzle efficiency and enhances protection of the anodes against external impacts,” says Mr Schwandt. It does so by moving the position of the anodes from the outside surface into the cross-section of the nozzle tail.

Another development has been the introduction of a retractable variant of Schottel’s rim thruster (SRT). This variant, SRT-R, covers a power range up to 500 kW for smaller vessels operating with an electric propulsion in shallow waters.

SRT-R has a thrust radius of 360º and low noise and vibration. It can be adapted for various operational profiles, including dynamic positioning (DP) duties, docking and casting-off in ports. SRT-R also functions as a transverse thruster in its retracted position. An electric motor stator is installed in the outer part of the tunnel, while the propeller blades are attached to the inside of the rotor. This converts electric power directly into propulsion power. Surrounding water permanently cools the electric motor, preventing it from overheating.

Permanent magnet additions

Steerprop has developed ducted propulsion with integrated permanent magnet (PM) motors for electric propulsion and environmental contra-rotating propeller (CRP) technology. Its development of Steerprop W was driven by operator requirements to enhance performance capabilities and cost efficiency in azimuth propulsion, says Steerprop director for sales and project management Juho Rekola. Steerprop W-series is “mechanically robust and has high hydrodynamic efficiency due to the shape of the frame” he says.

This manufacturer integrated PM motors within its azimuth Steerprop LM propulsors to deliver better efficiency compared to traditional induction motors. “We get more room in the vessel for other components and can avoid upper gear excitations in the hull,” says Mr Rekola, noting that larger units are in development.

Steerprop replaced upper gears with an electric motor integrated straight to propulsor’s vertical shaft. “For maximum reliability and service access we wanted to place the electric motor inside the vessel hull, instead of outside the hull below the waterline,” says Mr Rekola.

“The PM motor has lighter weight compared to an induction or externally excited motor,” he explains. “Its simple rotor structure also has reduced weight and inertia, making the motor construction simple and more robust.”

Steerprop researchers are developing the SP CRP ECO product line to focus on improving efficiency. “The whole propulsor is pressure-lubricated to lower mechanical losses compared with the commonly used oil bath lubrication technology,” says Mr Rekola.

“We are concentrating on optimising the shape of underwater parts to minimise flow resistance and take greater advantages of the contra-rotating propellers.”

Voith introduced a new thruster in June 2020 for all-electric propulsion on future vessels.

This electric version of the Voith Schneider Propeller (eVSP) combines a conventional VSP with the Voith inline thruster. It was developed for vessels involved in harbour operations, towage, offshore renewables and passenger ferries with electric propulsion, says Voith vice president of research and development for marine applications Dirk Juergens.

“With eVSP, we are making an important contribution to the electrification of the driveline in marine applications and thus to even more resource-saving shipping,” he explains. “eVSP was developed for all applications involved in the mobility revolution, such as offshore supply vessels, tugs and ferries.”

An eVSP uses a PM synchronous motor as its main drive, which is fully integrated into the VSP and significantly reduces the required oil volume and complexity of the propeller.

Removal of gears reduces noise to a minimum, frees space on a vessel and lowers maintenance requirements.

“No gears or transmissions are required, enabling stepless operation and virtually loss-free conversion of the electrical drive power with dynamic response characteristics,” says Mr Juergens.

In September, Voith secured a contract to supply VSP drives to two new Thyssenkrupp Steel

pusher boats being built at Barkmeijer Shipyards in the Netherlands. These diesel-electric-powered vessels will push barges on the Rhine in the Duisburg port area from 2021.

Podded propulsion

Kongsberg Maritime is developing a wider range of propulsors for different market segments, including azimuthing thrusters with nozzles in the US range installed on tugs, workboats and offshore vessels.

It is also developing ELegance pods for passenger ships and thrusters with PM motors, says Kongsberg general manager for propulsion sales Jussi Kuusisto. “Elegance units have the electric motor directly connected to the propeller,” he says. “And the azimuthing PM thruster has the electric stator inside the nozzle and permanent magnets located inside a ring that connects the propeller blade tips.

“Both of these products offer an increase in drive train efficiency due to the lack of gear wheels and are suitable for vessel types with high utilisation rates.”

Thrusters can be integrated with diesel-electric and hybrid propulsion systems. “A fully-electrical version has also been developed, where a vertical PM electric motor replaces the top gear of the Z-drive unit to form an L-drive system (PM L-drive),” says Mr Kuusisto.

Kongsberg is manufacturing two US255 azimuth thrusters with the PM L-drive solution for one of the first fully-electric harbour tugs being built by Damen Shipyards for Ports of Auckland. This will be a reverse stern drive (RSD-E 2513 design) tug with 70 tonnes of bollard pull.

As an example of a hybrid propulsion project, ABB is supplying Azipod propulsion, along with energy storage, automation, controls and generators, to two ferries Guangzhou Shipyard International is building in China for P&O Ferries’ cross-Channel routes.

Each ferry will have four Azipods, each rated at 7.5 MW. These systems provide 360º rotation of podded propulsors with lower vibrations and increase onboard vehicle space due to the location of the propulsor outside the hull.

Berg returns to consolidate manufacturing

In May, an old name in thruster provision returned when Caterpillar sold its propeller business to investment group Gula Skrinet, led by former Berg Propulsion chief operating officer Stefan Sedersten. Berg Propulsion has been reborn with manufacturing operations in Sweden and Singapore and offices in Shanghai, China, and Dubai.

In July, Berg announced it would invest in its Swedish manufacturing centre to produce controllable pitch propellers, azimuth and transverse thrusters, but would close its facility in Singapore in 2021.

“With this move we will form a single campus operation across all product lines located in Sweden just next to our research and development group,” said Berg Propulsion chief executive Stefan Sedersten, adding this “greatly expands the warehouse capacity, the amount of spare parts and swing units we have in our inventory.”

Berg supplies twin-fin propulsion with nozzled propellers for ship newbuilds and conversions. It also manufactures azimuth thrusters (MTA) with controllable or fixed-pitch propellers, in L-drive and Z-drive configurations and marine transverse thrusters (MTT) with rugged gears, bearings and customised blades.

MTAs are suitable for workboats, passenger ships and tugs. MTTs, enabling dynamic positioning applications, come with a controllable or fixed-pitch propeller.

Berg managing director Jonas Nyberg is presenting propulsion solutions during Riviera’s Alternative propulsion systems: the selection conundrum webinar on 1 October.

Brunvoll gains shuttle tanker propulsion orders

Brunvoll has become a leader in supplying thrusters for dynamic positioning (DP) shuttle tankers with the latest order for a new fleet, built by Hyundai Heavy Industries.

These orders are for three 155,000 dwt shuttle tankers AET has in production for exporting crude from Brazilian offshore oilfields.

Brunvoll is manufacturing two tunnel thrusters and three retractable azimuth thrusters, totalling 13,700 kW, for each tanker, in Norway.

It completed delivery of similar thruster systems in Q3 2020 to five shuttle tankers built at the Samsung shipyard for AET.

There are 84 DP shuttle tankers in operation and on order. Brunvoll has built a market share in the segment of 70%. It anticipates more shuttle tanker propulsion orders will come as older vessels in this segment are phased out as they complete 20 years in operation, which is the maximum operating period for shuttle tankers.

Related to this Story

Events

Offshore Wind Webinar Week

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

© 2024 Riviera Maritime Media Ltd.