Business Sectors

Contents

MTU matures a key engine technology

Turbocharger development at MTU – now a brand of Rolls-Royce Marine Power Systems in which Rolls-Royce and Daimler each have a 50 per cent shareholding – remains one of the German high-speed engine designer’s key in-house technologies.

Turbocharging shapes the characteristics of diesel engines more than almost any system, influencing fuel economy, emissions and dynamics. Turbocharger design expertise, MTU claims, enables its engines to meet the strictest emission requirements without sacrificing performance or dynamic response. High system integration with the engine secures a compact overall package with a low space demand.

MTU’s current in-house range of turbochargers embraces five series – the ZRT 12, ZRT 13, ZRT 35, ZRT 36 and ZRT 57 – which cover the requirements of engines with ratings from 400kW to 10MW.

Progressive in-house development and production allows MTU to match turbochargers and turbocharging systems across the engine programme as well as to create compact integrated packages for limited installation spaces.

Recent years have imposed tougher operating conditions on engines and support systems, subjecting power units to a high number of load cycles that impact on the service life of turbochargers. MTU takes these changes into account when developing its turbochargers as well as further optimising the time between overhauls to be in line with the engines. Simulation tools are exploited in the development process.

A new turbocharger emerges from a sequence of analytical optimisation processes in thermodynamics, structural mechanics, durability and containment strength, among others, before the unit is installed on the test bench. Analysis, MTU explains, fundamentally involves the optimisation of the components using 3D computational procedures for simulating the air flow and mechanical structural loads.

Such a process ensures that the turbocharger has the required performance characteristics and retains them throughout its entire service life.

Turbochargers are subjected to high thermal loads in operation, dictating that seals and bearings are thermally isolated and, if necessary, water cooled. To limit the surface temperature, MTU specifies a water-cooled impeller blade for highly turbocharged engines, simultaneously relieving some of the load on the intercooler.

In marine applications the turbine is cradled in a water-cooled connecting block, the turbochargers thus also satisfy the SOLAS directive stipulating that the surface temperature must not exceed 220ºC.

Within a design series, turbocharging is matched to the specific requirements of the application. For a power-generation engine always running at the same speed, a different turbocharger set-up to a vehicle engine (running from idling through to maximum rpm) is dictated.

A turbocharger can be set up for either a wide speed range or a high boost pressure. For engines intended for dynamic applications, MTU designs turbochargers to deliver sufficient boost pressure while covering as broad a range of engine speeds as possible. For applications demanding even more dynamic power response, the company adopts the sequential turbocharging principle.

In such a system, featuring sequentially linked multiple turbochargers, a single turbocharger produces the boost pressure for low engine speed operations, with additional units contributing when the engine is revving faster or when more power needs to be developed and supported by a sufficient charge of air to the cylinders.

Highly responsive dynamics – associated with MTU Series 890-engined military vehicles – can be addressed by variable turbine geometry. With such technology, the exhaust passes over adjustable wings to the turbine blades so that the turbine spools up quickly at low engine speeds and subsequently fosters high exhaust-gas flow rates.

Two-stage turbocharging is exploited to achieve high performance from new engine generations. In the early 1980s MTU equipped its Series 1163 engine with fully integrated two-stage turbocharging with intercooling. Up to five sequentially arranged turbocharger groups embracing high- and low-pressure stages enabled the engine to deliver 7,400kW.

Current engine development is influenced by the continual tightening of emission standards. Systems inhibiting the production of diesel particulates or nitrogen oxides during the combustion process or that secure cleaner exhaust through exhaust gas recirculation (EGR), selective catalytic reduction (SCR) or diesel particulate filtration (DPF) have to be integrated into overall engine designs.

For MTU, turbocharging is one of the key technologies in low-emission concepts because it is only with a compatible turbocharging system that the tendency of these additional measures to negatively affect engine performance and responsiveness can be prevented. A common feature of all emissions-reducing technologies is that they diminish the effect of the turbocharging.

The Miller process, EGR and DPF create a higher exhaust back-pressure, while EGR also increases the air mass that has to be delivered to the cylinder. The turbocharger has to compress the air at a higher rate (it must force more air into the combustion chamber to provide the same amount of oxygen for combustion as before).

MTU research has shown that single-stage turbocharging as previously applied will no longer be sufficient for most applications in the future. Propulsion system specialists, it says, will opt for regulated two-stage turbocharging systems for engines designed to comply with tough emission standards.

Such a system ensures a constantly high rate of intake air delivery to the engine at all operating points and even under extreme ambient conditions (intake air temperature and back-pressure, for example). Two-stage turbocharging is based on pre-compression of the intake air by low pressure turbochargers followed by further compression in high pressure turbochargers.

Turbocharger system control is integrated into MTU’s Engine Control Unit (ECU) electronic engine management system, which was developed in-house.

MTU’s innovative regulated two-stage turbocharging system will be used for the first time for the Series 4000 engine in rail applications, enabling EU Directive 97/68/EC Stage IIIB emission requirements for diesel locomotives (in place since 2012) to be met. The system is planned for implementation on the current engine series for other mobile applications.

For stationary power-generation applications, where the demands on turbocharger dynamic response are not so high, the more economical single-stage turbocharging will continue to be applied.

When air is compressed by the turbocharger, it heats up. Intercooling further increases the air density so that a greater air mass and hence more oxygen enters the cylinder. The regulated two-stage turbocharging system operates with two intercoolers: the first is located between the low-pressure (LP) and the high-pressure (HP) stages; and the second downstream of the HP stage.

Intercooling achieves more efficient compression in the subsequent HP stage, leading to a higher efficiency level in the turbocharging system. The intercoolers are highly integrated in all MTU engines and have a very small space requirement.

• Single-stage turbocharging: the boost pressure for the entire range of engine speeds and loads is generated by a single turbocharger.

• Sequential single-stage turbocharging: in this setup one turbocharger runs at low speeds and the second turns on a predetermined engine speed or load by means of valves in the intake and exhaust systems.

• Sequential two-stage turbocharging: operates in the same way as sequential single-stage turbocharging but, instead of an individual turbocharger in each case, a pair of turbochargers is added or disconnected as required.

• Regulated two-stage turbocharging: two turbochargers are connected in series. In the system configuration adopted by MTU the exhaust flow from the cylinders is split so that part of it passes through the high-pressure turbine and the rest is diverted through a bypass by a controllable waste-gate valve. The entire mass flow then passes through the low-pressure turbine. WTG

Related to this Story

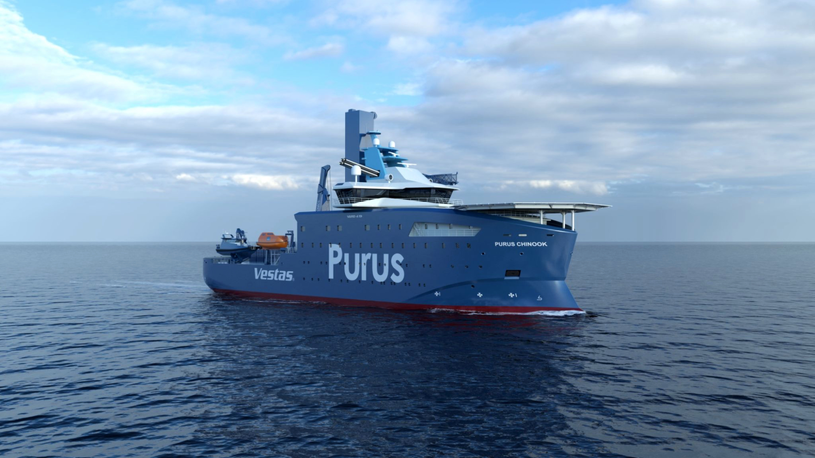

AI, digital twins help design cyber-secure, green SOVs

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.