Business Sectors

Events

Contents

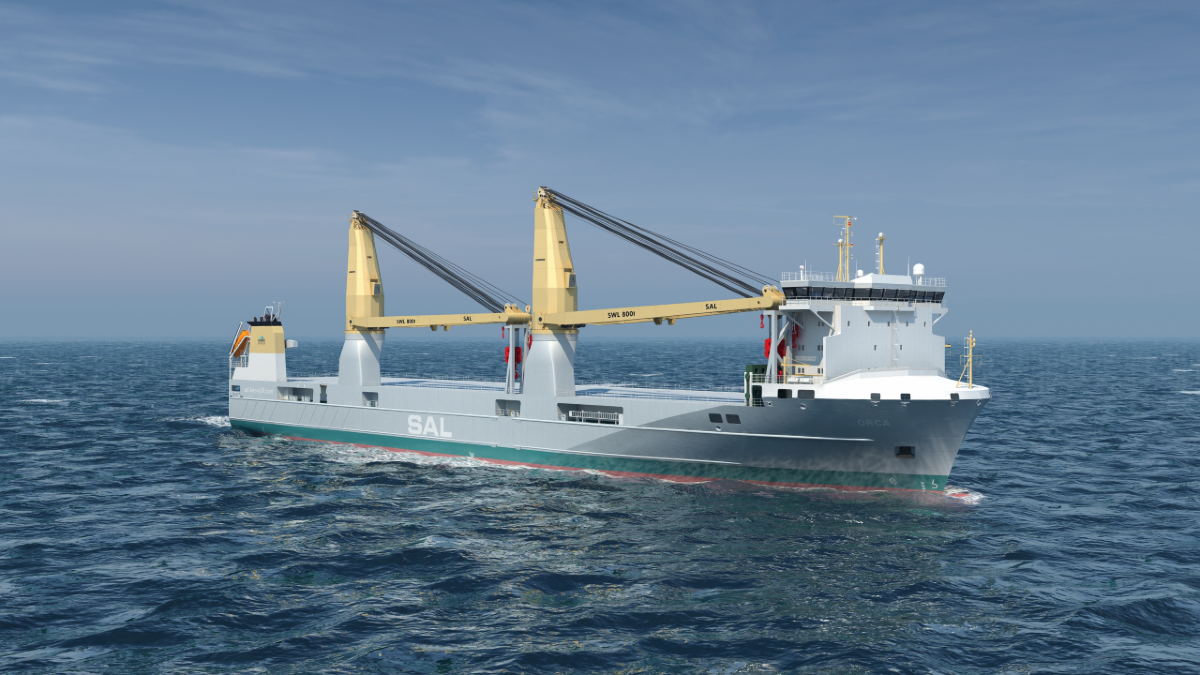

New class of heavy-lift vessels aims for ‘carbon-neutral transport’

A German-Dutch joint venture maritime heavy-lift and logistics company aims to offer clients carbon-neutral transport solutions with a new class of heavy-lift ships on order in China

These 14,600-dwt Orca-class heavy-lift ships are being built for Jumbo-SAL-Alliance, a JV between German shipping company SAL Heavy Lift and Netherlands-based Jumbo Shipping. With the combined input and experience of both companies, the Orca class has been designed and developed by SAL Engineering, a sister company to SAL Heavy Lift, which are both part of the Harren Group.

Owner and chief executive of SAL Heavy Lift, SAL Engineering and the Harren Group, Dr Martin Harren, said the Orca class vessels “represent the new benchmark both in terms of their technical capabilities and modern climate-friendly propulsion systems,” adding they “will be the most efficient vessels in their class, with consumption and emission figures far superior to any existing heavy-lift vessel today.”

Among the key technologies integrated into the Orca class are optimised hull forms, methanol dual-fuel engines and propulsion systems that include a “diesel-electric booster function” in hybrid setup with a broad range of economic speed settings and redundancy, according to the owner. Jumbo-SAL-Alliance plans to operate the ships on green methanol when it becomes available at ports to offer their customers carbon-neutral transport solutions.

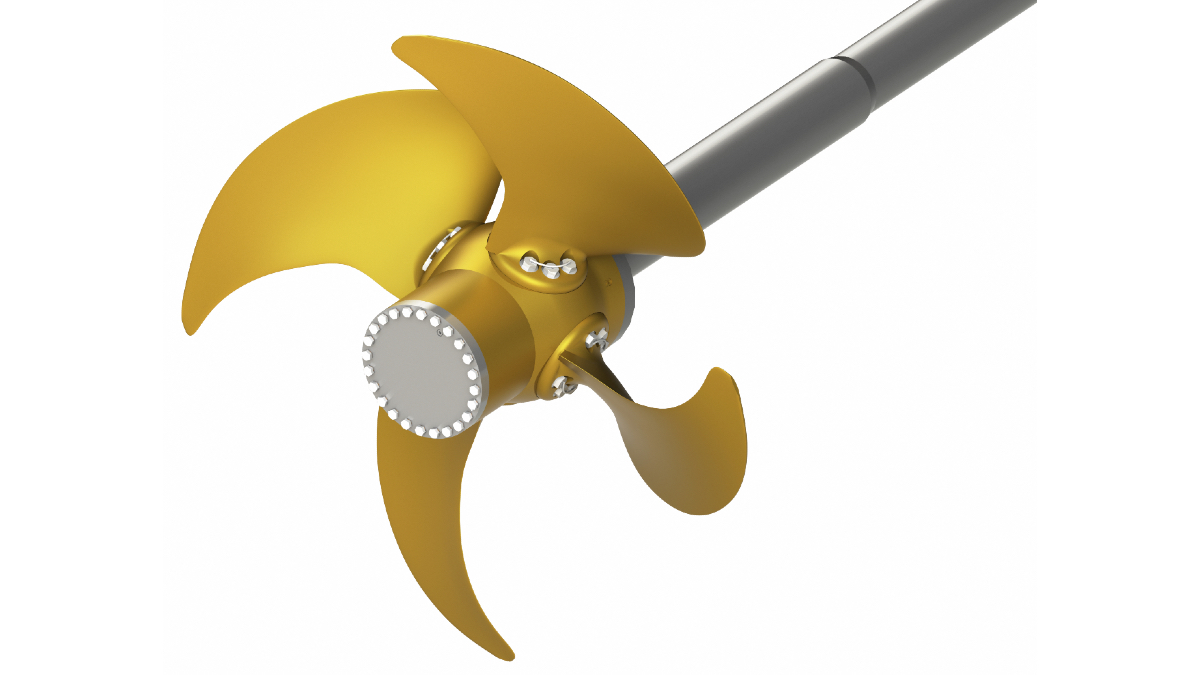

Critical to each of these ship’s energy efficiency and fuel consumption will be 6-m Schottel controllable propellers (SCPs). Each ship will have four-bladed SCP 129 controllable pitch propellers with an input power of up to 8,810 kW.

To optimise the propulsion systems for the Orca-class vessels, SAL Engineering performed hydrodynamic calculations on three competing propeller designs at two independent model test facilities, China Ship Scientific Research Center and the Shanghai Ship and Shipping Research Institute.

Open water, self-propulsion and cavitation model tests were carried out, with evaluations conducted based on SAL’s predefined requirements covering propeller efficiency, cavitation behaviour and propeller-induced hull pressure pulses. The tests showed Schottel’s bespoke propeller design, with an almost cavitation-free operation and an optimised open water curve, meeting SAL’s requirements.

SAL Engineering project engineer Florentin Edler said these tests were needed to objectively compare all different competing propeller designs. “When it now came to equipping the Orca class, Schottel’s hydrodynamic team once again had proven their expertise, which was the key to them winning the contract.”

The SCP is a customised combination of propeller blades, propeller shaft, coupling, stern tube, hydraulics and sealing. The hydraulic and lubrication oil system is designed for the use of environmentally acceptable lubricants to comply with US EPA VGP regulations.

Siemens Gamesa Renewable Energy will take the first two Orca-class heavy-lift vessels under long-term charter starting in mid-2024, employing the cargo ships to transport massive wind turbine components for offshore windfarms.

At a service speed of 15 knots, the Orca-class vessels will consume “significantly less” than 20 tonnes of fuel oil per day – like far smaller-sized and geared MPP vessels, according to SAL Heavy Lift. At 10 knots, fuel consumption is expected to be 6 tonnes per day.

Projects by the owner suggest NOx emissions will be 10% below IMO Tier 3 levels while undercutting EEDI phase 3 limits for CO2 emissions by 21%.

Riviera Maritime Media’s Maritime Decarbonization Conference, Americas will be held 12-13 December 2023 in Houston, USA. Use this link for further information and to register your interest

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.