Business Sectors

Events

Marine Coatings Webinar Week

Contents

Propulsion expertise 100 years in the making

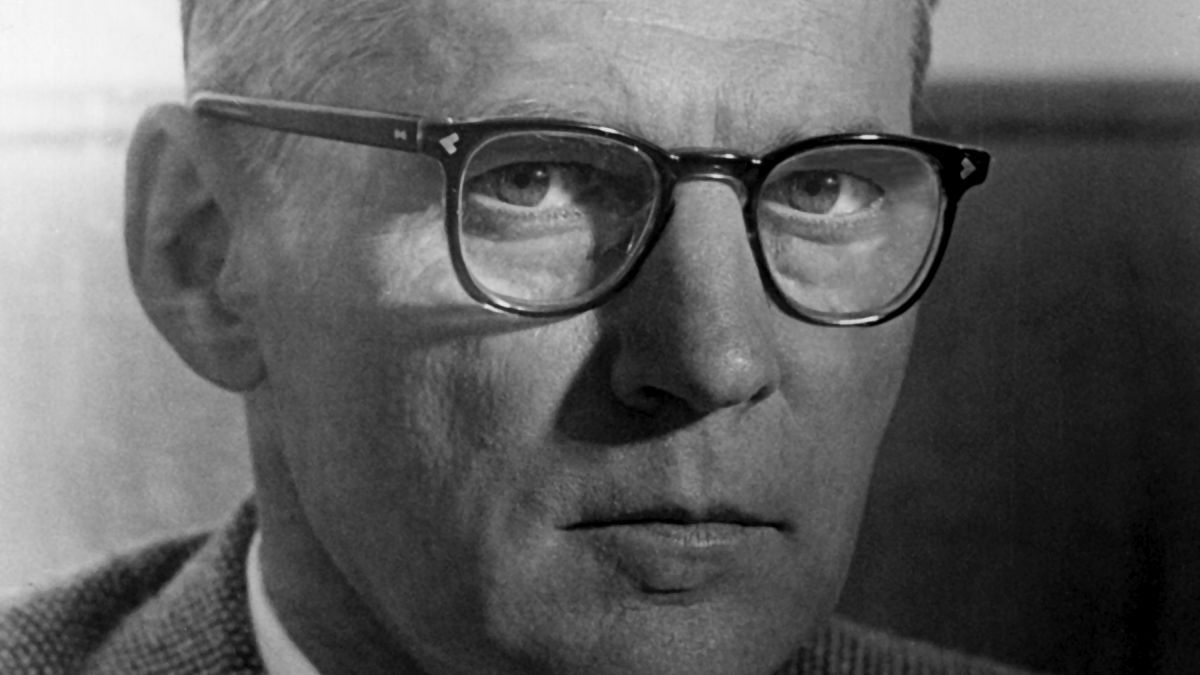

Building on the success of its founder Josef Becker and the Rudderpropeller, German propulsion specialist Schottel marks its 100th anniversary

Maker of the ubiquitous Rudderpropeller, German propulsion specialist Schottel will mark its 100th anniversary this year since its founding by inventor Josef Becker in 1921. A trained locksmith by trade, Mr Becker opened his workshop, J. Becker Maschinenbau-Werkstätte, in a barn in Niederspay, a small German village on the Rhine, to initially repair water pumps for local farmers.

In 1925, Mr Becker transitioned the focus of his business from land to water: he developed a manoeuvrable ‘unsinkable’ sloop – built with large, permanently installed air boxes for a local baker to transport flour. Only a few years later, Mr Becker started designing and building motorboats, at that time still a novelty on the Rhine. To meet the growing demand for production space, he built a shipyard in 1934 on a nearby plot of land at Rhine kilometre 578.4 – the river section known as Schottel.

Before the shipyard closed in 1973, more than 16,000 sloops were produced by the Schottel shipyard.

At the end of the 1940s, Mr Becker began testing a propulsion system that would revolutionise shipping: the 360-degree, steerable Schottel RudderPropeller. As a starting point for his concept, Mr Becker used the well-known outboard drive. He struck upon the solution by using a Z-drive without a separate rudder blade, but with a propeller that can be steered 360 degrees around its own axis without any restrictions. As a result of his work, steering and propulsion were combined for the first time, providing vessels with full power while turning and manoeuvring. With this invention, Mr Becker paved the way for Schottel’s future growth.

In 1967, Schottel supplied Rudderpropellers to Janus — the first harbour tug fitted with the propulsion innovation.

In 1958, Schottel Netherlands was founded as the first subsidiary abroad, followed by more than a dozen others worldwide. Schottel is now represented in all of the world’s key shipping centres, and the international Schottel Group employs around 850.

Schottel’s penetration in the propulsion market goes well beyond the global tugboat sector. At the end of the 1990s, new developments for the ferry market enabled the move from the harbour basin to the high seas. During the offshore oil and gas boom, which continued until 2015, Schottel secured a 20% market share in the offshore supply vessel segment.

In 1998, Schottel acquired Wismarer Propeller und Maschinenbau GmbH (WPM), expanding its product range to include controllable-pitch propellers up to 30 MW. Retractable and large SRP units are manufactured in Wismar today.

Outgrowing its original location in Spay, Schottel opened a new production site in nearby Dörth in 2015. There, the traditionally high vertical range of manufacture was expanded and the production capacity increased by about 30%.

“The vessels that are built today will be in the water for decades to come”

With the invention of the Rudderpropeller in 1950, Josef Becker laid the foundation for Schottel becoming one of the world’s leading manufacturers of vessel propulsion systems. Decades of expertise in the field of propulsion combined with evolving technologies has enabled Schottel to offer a wide range of innovative and future-oriented products and services.

Schottel propulsion systems can be found in tugs, offshore support vessels, ferries, passenger vessels, yachts, merchant ships and navy and government vessels. This applies equally to new vessels and to modernisations. Automation, propulsion control and hybrid propulsion systems extend the product range, which is supplemented by marine services.

Schottel Rudderpropellers continue to be popular choices in tugs. Most recently, Brazilian towage company Starnav choose Rudderpropellers for a series of four 80-tonne bollard pull newbuilds.

Each azimuth stern drive tug features two diesel-driven Schottel rudder propellers, type SRP 490 at 2,525 kW each, featuring fixed-pitch propellers with a diameter of 2.8 m. With this thruster configuration, they will achieve more than 80 tonnes of bollard pull and a maximum speed of 12.5 knots.

One of the 32 m escort tugs has Schottel’s patented Sydrive-M technology from the start, while the other three will be configured to be Sydrive-ready.

Sydrive is a mechanical hybrid drive system without the costly complexity of common hybrid technology, to help lower maintenance costs and fuel consumption.

Starnav chief executive Carlos Eduardo Pereira says: “By using Schottel’s hybrid solution, we [are seeking] clean operations. Starting now is particularly important: the vessels that are built today will be in the water for decades to come.”

“Our history is marked by bold decisions at the right time”

He continues: “Our focus has always been the high level of reliability in the equipment, mainly safety and environment care. With 34 vessels propelled by Schottel in our fleet, we will continue expanding our operations and benefit from a strong partner with extensive know-how in Brazil.”

The Sydrive-M connects a port and starboard-mounted azimuth thruster in one vessel, allowing the thrusters to be driven together by only one of the main engines. The system needs no additional electronical components, which offers many advantages, as demonstrated in three main operation modes: light operation or free sailing mode, full thrust operation mode and FiFi mode.

In turn, the configuration helps reduce the operating hours of the main engines and results in lower maintenance costs and reduced carbon emissions.

Starnav has contracted Detroit shipyard in Itajaí, Brazil to equip the tugs with the Schottel Rudderpropellers. The first of the tugboats will enter service in 2022.

Bitumen tanker and beacon vessel

Rudderpropellers are just part of Schottel’s portfolio of propulsion products. A new 15,000- dwt bitumen tanker being built in China Merchants’ Jinling shipyard for France-based Rubis Group will feature a pair of Schottel EcoPeller azimuth thrusters for main propulsion. The two electrically-driven Schottel EcoPellers type SRE 560 (2,050 kW each), have fixed-pitch propellers with a diameter of 3.1 m.

With this configuration, the 145-8 m long, 26.2-m wide vessel will achieve a maximum speed of 13.55 knots at design draft.

Also included in the propulsion package is a Schottel TransverseThruster type STT 2 (600 kW) to ensure maximum manoeuvrability.

This is believed to be a particularly effective combination of powerful propeller thrust and course-stabilising fin, as the Schottel EcoPeller fulfils all the requirements of a modern high-performance propulsion unit.

The hydrodynamically optimised design allows the Schottel EcoPellers to produce maximum steering forces and enables excellent efficiency and course stability, reducing fuel consumption and lowering operating costs and emissions.

Model tests carried out at the maritime consulting company SSPA Sweden confirm the performance of the EcoPeller: when compared with a conventional rudder propeller with nozzle, it demonstrated a 17% increase in propulsion efficiency at an operational ship speed of 12.5 knots throughout testing.

To achieve the maximum ship speed of 13.55 knots at design draft, the Schottel EcoPeller requires 11% less propulsion power than a conventional rudder propeller with a nozzle.

EcoPellers are being applied as main propulsion in a new Chinese ice-breaking beacon vessel. Haixun 156 has recently been launched by Wuchang Shipbuilding Industry Group in China’s Hubei Province. It was ordered by the Tianjin Maritime Safety Administration (MSA) and is scheduled to enter operation in September 2021.

Its main propulsion consists of a pair of diesel-driven Schottel EcoPellers type SRE 460 at 1,800 kW, each featuring a four-bladed propeller with a 2.4-m diameter.

A transverse thruster type 500-kW STT 1 will enhance the ship’s manoeuvrability and provide dynamic positioning capabilities, allowing the ship to reach a free sailing speed of 14.5 knots.

EcoPellers are an ecologically clean propulsion system, primarily developed for open seas and coastal operating conditions. The combination of propeller thrust and course-stabilising fin helps the system fulfil the requirements of a modern high-performance propulsion unit.

Haixun 156’s azimuth thrusters are ice-strengthened to China’s ice-class CCS 2 (corresponding to Finnish-Swedish ice class 1B) to enable the vessel to break through ice as thick as 0.6 m, guaranteeing emergency response in North China’s waters, even under extreme weather conditions.

The 75 m vessel has a displacement of 2,400 tonnes and will be deployed for setting up, removing, swapping and maintaining navigation aid facilities at ports and on navigation routes in North China.

The ship will help support Tianjin Port’s navigational security centre. The MSA Beihai Navigational Security Center’s Tianjin Aids to Navigation system is responsible for the maintenance of all navaids within the Tianjin area.

Besides serving vessel owners, ship designers and shipbuilders through its worldwide sales and service network, Schottel continues to support its customers by offering technical seminars locally or at one of its four training centres and online.

“The customer is the focus of our daily business,” says Mr Kael. “Those in the maritime industry who turn to Schottel have always been able to expect products and services of the highest standard. Our goal is to be the first choice in marine propulsion solutions. To this end, we use our entire wealth of experience and all our innovative strength to improve existing areas and expand into new ones. This and the powerful heritage of Josef Becker will help us to stay on course for a bright future.”

Related to this Story

Events

Marine Coatings Webinar Week

Maritime Environmental Protection Webinar Week

Ship Recycling Webinar Week

© 2024 Riviera Maritime Media Ltd.