Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

US Navy turns to non-traditional defence start-up for fleet of ASVs

Navy awards US$392M contract to Texas-based defence technology company to build fleet of autonomous surface vessels

In the next few years, the US Navy will be adding a fleet of small robot ships produced by Texas-based defence start-up Saronic Technologies, following the award of a contract worth US$392M.

While details of the other transaction agreement were scarce as announced by US Secretary of the Navy John C Phelan on X on 8 December, the deal represents a significant step for Navy vessel acquisition and puts the budding Austin-based defence tech company on the fast track. Secretary Phelan tweeted the project “proves how we’ll build a hybrid manned–unmanned fleet: open competition, real contracts, real hardware for sailors and marines, not slides. This is now the standard.”

With the threat of the Chinese shipbuilding juggernaut looming, the US Navy is looking to quickly advance autonomous capabilities in its fleet and is opening acquisition pathways to non-traditional defence companies such as Saronic.

Prior to the announcement, company co-founder and chief operating officer, Doug Lambert spoke with Riviera at the International Workboat Show in December, sharing details of Saronic’s US$300M investment to expand the former Gulf Craft, Franklin, Louisiana shipyard, its line of autonomous surface vessels (ASVs) and how it plans to modernise US shipbuilding.

An electrical engineer who started his career in robotics, Mr Lambert worked in previous start-ups that served as “jet fuel” for his career; his efforts at Liquid Robotics – later acquired by Boeing - helped pioneer Wave Glider, one of the first unmanned surface vehicles with robotics. Another venture with a Texas-based autonomous submarine company led him to connect with his three fellow Saronic co-founders: company chief executive Dino Mavrookas, chief commercial officer Rob Lehman, and chief technical officer Vib Alterkar.

While its roots are in small uncrewed surface vessels, Saronic’s “vision was always to push into shipbuilding and help rebuild the maritime base,” said Mr Lambert. What was clear in speaking with Mr Lambert is his passion to create, innovate and boost the US maritime shipbuilding base.

In comparing the current state of manufacturing in the US, Mr Lambert said he “never liked the term ‘re-industrialise’”, noting past industrial achievements like the Hoover Dam and Interstate Highway System. “But how do we take next-level engineering principles, next-level production principles, revive the process knowledge in the United States, and build ships to scale?”

One way that Saronic plans to do that is by building on its accumulated experience in producing smaller ASVs at its Austin facility. It is already expanding the facility’s footprint to support the manufacture Corsair, a 7-m-long ASV for US Navy missions with a range of 1,000 nautical miles (nm), payload capacity of about 450 kg, and a top speed of 35+ knots.

Franklin expansion

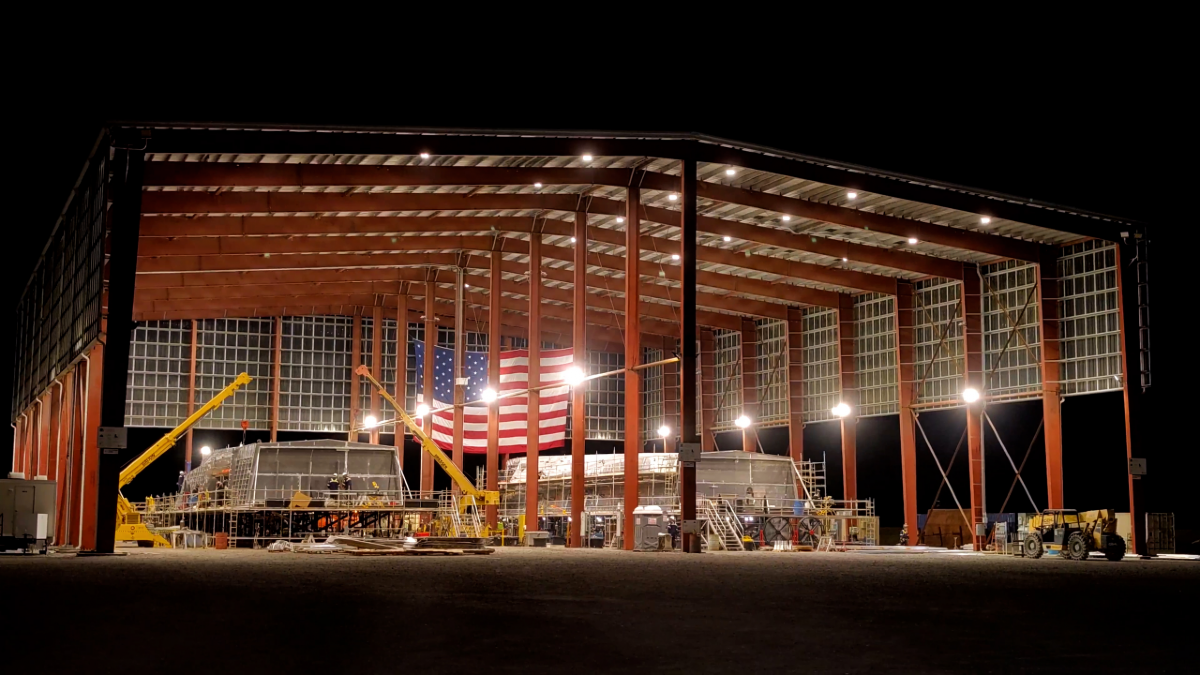

Mr Lambert said Saronic’s US$300M investment in the Franklin shipyard will allow it to expand in multiple phases, with a dedicated production line to build larger ASVs like Marauder, the company’s 55-m medium unmanned surface vessel with a projected range of 5,400 nm (with a baseload of 25 tonnes), cruising speed of 12 knots and ‘burst’ speed of more than 25 knots. Two Marauder vessels are under construction in Franklin.

While the production line is expected to be highly automated, the shipyard will need to ramp up and train its workforce, which is expected to grow from the current 100 to some 1,500 over the next few years.

When it becomes fully operational in early 2027, the expansion will add more than 27,870 m2 of new production capacity.

“There are talented Americans who want to build ships if the environment is right and the opportunity is there,” said Mr Lambert. “It’s on us in industry to make sure that we provide those opportunities,” he concluded.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.