Business Sectors

Contents

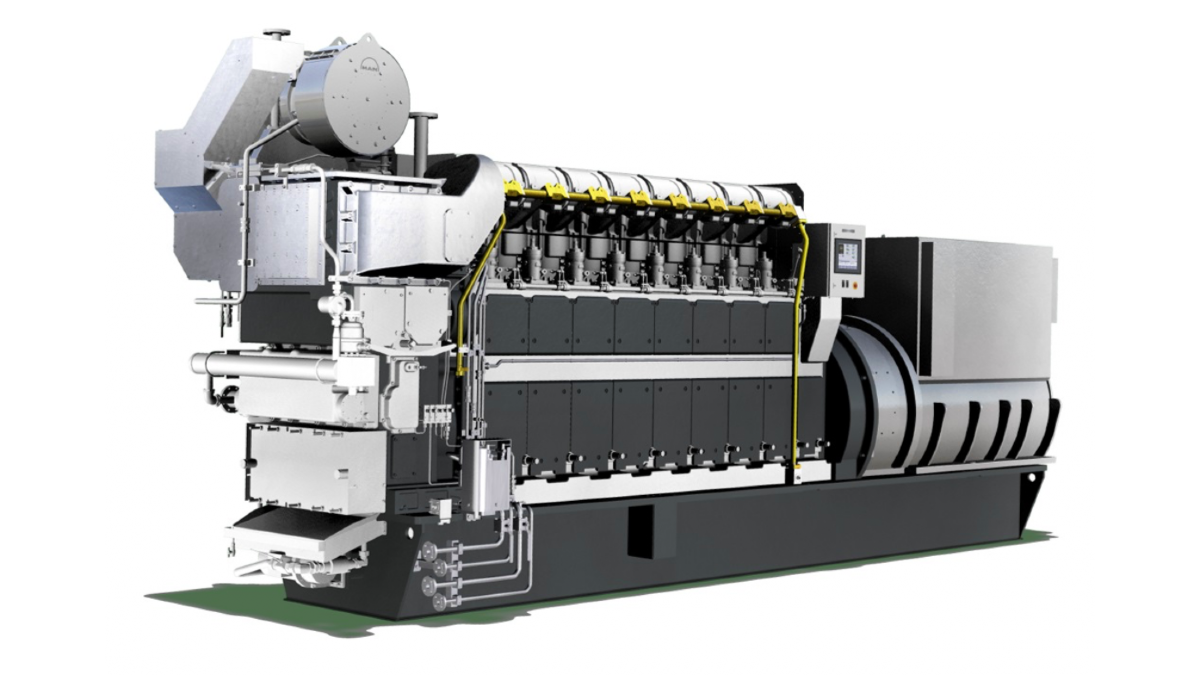

Hydrogen and hybrid hold promise for cleaner engines

To meet the industry’s greenhouse gas emission targets, engines need to burn fossil-free gas and be supported by energy storage

Tackling both global and local emissions is harder than it sounds. Speaking at Riviera Maritime Media’s Sulphur Cap 2020 Conference in Amsterdam on 8-9 May, Wärtsilä director of system integration and performance Patrik Baan explained that although solutions are already in service that tackle local emissions such as SOx and NOx, they can come at the expense of increasing the global emissions that will have a long-term impact around the world.

The case of scrubbers – of which Wärtsilä is a major supplier, having sold over 300 in the second half of 2018 – is a good example. First, they need energy, adding up to 2% to a vessel’s power requirements just to keep the water systems running for an open-loop scrubber. And of course, they enable the continued use of high-carbon fuel.

The impact of NOx reduction technology, to meet IMO’s Tier III limits, is less familiar. The drop in pressure that selective catalytic reduction (SCR) causes is known to engineers – lower pressure means that more energy (and therefore more fuel) is required to push gas through the unit. But Mr Baan explains that the big issue for SCR as engines become more efficient is exhaust gas temperature.

“For four-stroke engines, selective catalytic reduction is normally at the back of the engine, behind the turbocharger,” he says. “But with better turbocharger technology exhaust gas temperatures have gone down. More efficient engines mean less waste heat and lower exhaust temperatures.”

Patrik Baan (Wärtsilä): "We can burn hydrogen in today’s engines"

As SCR cannot operate at low temperatures, Wärtsilä has introduced a new tuning parameter to enable NOx reductions in its most efficient engine, the Wärtsilä 31. The two-stage turbocharging process on the engine means that the exhaust gas provides little heat for the catalytic reduction process, so a high-temperature tuning (called High T6) reduces the engine efficiency.

“The best use of hybrid power is to size your power for average, rather than maximum load”

“So we can use an SCR to get the NOx down on these engines, but we need to worsen efficiency and therefore increase CO2 emissions to get there,” says Mr Baan.

There is then an inherent challenge in tackling greenhouse gas emissions at the same time as reducing ‘local’ emissions such as SOx and NOx. For more than one reason, gas-burning engines may hold the answer.

Wärtsilä deploys different technologies to burn the various hydrocarbon fuels on the market today, explains Mr Baan. For the lower-carbon fuels such as LNG, it deploys either pure-gas, spark-ignited engines or dual-fuel engines, both of which use the lean-burn Otto cycle combustion principle. For conventional, higher carbon fuels, it uses Diesel cycle engines with a higher injection pressure. As well as having an impact on CO2 emissions, this also has an impact on NOx formation and therefore the efficiency that can be achieved in an engine.

“The nice thing about the Otto cycle is that it has lower temperatures, which means less NOx formation,” says Mr Baan. “So these engines can meet NOx Tier III requirements without after-treatment.”

That lack of after-treatment is crucial. It means that no compromise needs to be made in engine tuning, and Wärtsilä can deploy the entire efficiency benefit of newer, better engine technologies.

“Take two-stage turbocharging on the Wärtsilä 31,” he says. “We can really use that to its full extent if we don’t have to reduce efficiency to increase the exhaust temperature for SCR. In the future we may even see three-stage turbocharging. We know that engines using gas will benefit much more because this temperature constraint is not there.”

The next step

But although using low-carbon fuels is a step in the right direction – enabling reduced CO2 both inherently and by not demanding emissions aftertreatment – it is not enough.

“If we want to take the next step we will need to go towards no-carbon, non-fossil fuels,” says Mr Baan. “We have been looking into this area and have done several tests on hydrogen.”

Taking its spark-ignited and dual-fuel engines, Wärtsilä has performed tests mixing quite a high proportion – up to around 25% – of hydrogen with natural gas in its Otto-cycle engines.

The initial results, using standard engine tunings, were not entirely encouraging. The combustion characteristics of hydrogen meant that combustion was accelerated. This extra heat led to an increase in NOx formation. The faster heat release also meant that peak pressures within the cylinder were higher.

On the positive side, Wärtsilä confirmed that, as expected, the lower carbon content of the fuel mix led to lower carbon emissions. Methane slip was also reduced due to the more violent combustion of hydrogen burning the gas more completely.

“We can use an SCR to get the NOx down on the engines, but we need to worsen efficiency and therefore increase CO2 emissions to get there”

Just as turbocharger tunings were needed to enable the use of SCR with Wartsilä 31, so here tunings made all the difference. By using alternative injection and spark timings to try to bring NOx down to Tier III compliance, researchers were able to lower the impact that the hydrogen content had on heat pressure, as well as offering lower total carbon emissions.

“So the answer is yes, we can burn hydrogen in today’s engines,” confirms Mr Baan.

But although Wärtsilä may be able to use hydrogen as part of the fuel mix for some of its engines, the answer to reducing carbon emissions does not lie in the engine alone.

“The energy consumption of internal combustion engines is quite linear,” he explains. “If you take out half the power you need to put in half the fuel. So going slowly saves fuel and if you really want to save fuel you need to downsize your plant. That is the hybrid opportunity.

“Batteries are amazing, but apart from the cost there is also the volume – if you wanted to sail around the world you would need a much bigger ship. And while our experience of electric vessels is that they are great if you want to take a 20 km trip, it is quite a different story if you want go 1,000 km in one go.”

The idea of peak shaving has gained a lot of traction in early iterations of hybrid propulsion. The idea is that engines run on a continuous load, with batteries discharging when a peak demand is encountered and charging when the engine output exceeds energy demand. But Mr Baan is not convinced that is always a good solution.

“The dynamics have an impact,” he says. “There is the constant charging and discharging and then you need to install frequency converters. Even within Wärtsilä it depends who you ask about whether peak shaving is worth it.”

The best use of hybrid power, says Mr Baan, is to size your power for average, rather than maximum load.

“What traditionally happens is that we typically tend to install more than enough power. So you have a big engine or a number of gensets running part load in case the load increases. But if you can scale your engines for average power and then use energy storage – whether it is batteries or supercapacitors or something else – to take the peaks, that would be a more efficient solution.”

By harnessing hybrid power and lower carbon fuels, Mr Baan believes that enginebuilders can tackle the challenge of beating both local and global emissions.

Related to this Story

Events

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

CO2 Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.