Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

MAN puts emphasis on both products and services

Wide power range covers most engine types and sizes, using all fuels types

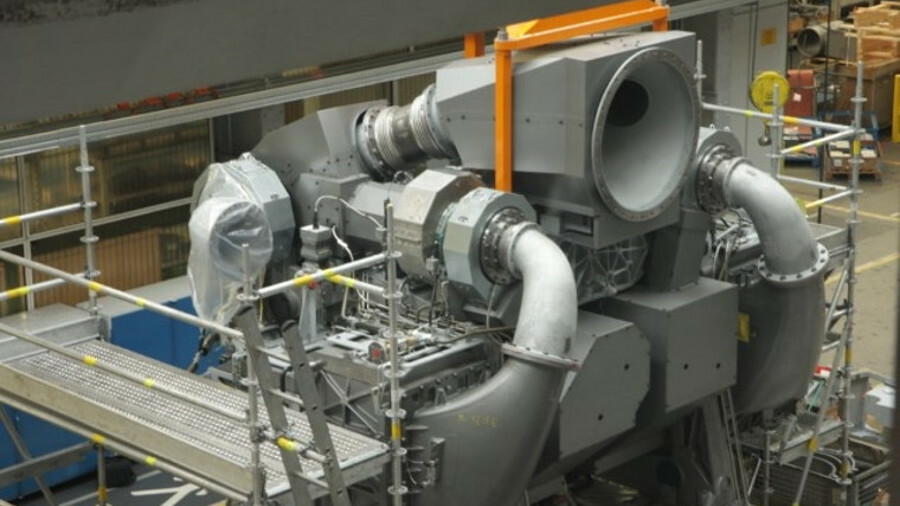

With equipment installed on 50,000 engines worldwide, MAN Diesel and Turbo SE, of Augsburg, Germany, is one of the world’s leading suppliers of turbocharging solutions. Covering engine capacities from 300 kW to 30,000 kW per turbocharger, the MAN range meets the demands of both two- and four-stroke marine propulsion engines and auxiliary power packages. MAN turbochargers are designed to operate on engines using all types of marine liquid fuels, including both medium and heavy fuel oils, and increasingly popular gas fuel alternatives.

The MAN turbocharger portfolio is headed up by the TCA series, for two- or four-stroke engine applications power capabilities of up to 30,000 kW per turbocharger. These axial flow turbine units can run with engine exhaust gas temperatures of up to 650°C and can deliver charge air pressure ratios of up to 5.5:1. Available in six frame sizes, they feature low-loss floating bearings with all oil pipework integrated into the design to allow simple installation. Noise emissions levels are low and a major service advantage for the TCA is the ability to change compressor wheels without needing to re-balance the full rotor.

The achievement of IMO Tier II emissions levels is unquestioned but MAN technologies also provide a range of possibilities to assist in meeting vessel EEDI targets. With the EEDI measuring point set at 75% of engine maximum continuous rating, however, this is not the only driver for operators in seeking higher efficiencies. Many vessels now use slow-steaming to reduce fuel use and major fuel savings can be made when engines are operating in the 25-50% power band.

To optimise slow-steaming savings for vessels with multiple engine turbochargers fitted, a turbocharger cut-out system is a viable option. This can be used at lower engine powers and enables one or more turbochargers to be isolated either automatically or manually, resulting in optimised turbocharging. Although not directly contributing to EEDI at these loads, fuel savings up to 6 g/ kWh can be achieved and the system also assists in meeting Tier II emissions targets.

Further options available from MAN include electronic control tuning (ECT) for the engine and variable turbine area (VTA) for the turbocharger. With the latter, delivery of charge air can be matched exactly with fuel injection rates at all engine speeds and loads, reducing specific fuel oil consumption by up to 5 g/ kWh and making a positive contribution to EEDI. Where required, exhaust gas bypass (EGB) technology can also be added, allowing better matching at lower engine loads and spilling excess exhaust gas at higher loads. Again, up to 5 g/ kWh fuel savings are possible using this approach and there can also be a noticeable benefit at the 75% EEDI measuring point.

A step change in turbocharger technology is also available from MAN with its two-stage Ecocharge solution. Available for engine powers of up to 20,000 kW, these turbocharging systems can operate at efficiencies of up to 80% and deliver pressure ratios of up to 10.5:1, which enable increased power density combined with the lower emissions resulting from Miller cycle valve timing. MAN already has extensive experience in two-stage applications with 2,000 turbochargers having been delivered for this purpose and approximately 10,000,000 operating hours accrued.

The first stage of Ecocharge systems use a TCA, TCR or new TCT design turbocharger with a TCX unit – specifically designed for higher pressures – providing a second-stage boost. Available in eight frame sizes, the TCX has a turbine of mixed flow design and can operate at high air-side pressures and in engine exhaust gas temperatures of up to 650°C. Intercooling between compressor stages is available and the result is both increased efficiency and a package that will assist engine manufacturers in meeting stringent IMO emissions limits.

MAN’s turbocharger products offer what the company describes as class-leading efficiencies but, looking ahead, MAN is also well advanced with systems for IMO Tier III compliance, having favoured high-pressure selective catalytic reduction (SCR) and EGR systems as solutions for two-stroke engines. For high-pressure EGR using the ‘short route’ approach, MAN now has an electrical turbo blower (ETB) product available to overcome the pressure difference between the exhaust gas and the scavenge air receiver. The variable speed of the ETB drive motor allows accurate control of the volume of exhaust gas recycled to the inlet and hence the optimum emissions performance of the engine.

Global network plays key role in MAN’s service plan

A key part of MAN’s customer service is its ability to support equipment throughout its life using the worldwide MAN PrimeServ network. The company sees customer support as being critical to business success, not only for aftermarket needs but also as a factor for new equipment orders. Its experience is that the global ability of PrimeServ to deliver this support provides customers with the confidence that through-life service demands will be met efficiently and effectively. This is particularly important for the marine industry where vessel routes will often vary, making competent local support for both engines and turbochargers essential.

The PrimeServ network consists both of MAN facilities and those of licensed associate companies but, in all cases, engineers and technicians are fully trained and certified by MAN before licensees are approved to provide repair and maintenance services. All engines and turbochargers are covered and rapid delivery of spare parts to PrimeServ workshops ensures equipment downtimes are kept to a minimum. Many regular spares are held at worldwide locations but the MAN logistics systems enable most parts to be delivered within 24-48 hours, even if not held in local stocks.

PrimeServ engineers undergo continuous training to ensure that are fully up to date in their knowledge of equipment and overhaul processes. This is assisted by regular information updates through service bulletins and video clips. Close co-ordination is maintained with all licensees, ensuring all work carried out meets company standards and is fully quality assured. Service is available on a 24/7 basis and backed up by technical support from MAN engineers and technical experts.

The result is a cost-effective and efficient support service for turbochargers and engines throughout their operating lives. Full overhaul facilities are available in service centres but in-situ inspection and assessment work can be carried, out using borescopes to evaluate turbocharger condition. Vibration measurement and analysis can also be carried out on units in operation to evaluate likely root causes in the event of any vibration problem being identified.

In addition to new part supplies, MAN offers repair and reconditioning services of key turbocharger parts at its Augsburg base. This allows operators the option of a potentially lower-cost route to extending the service lives of installed units. Examples of repairs include turbine shaft and bearing surface recovery, diffuser wall recovery and weld repairs to address minor damage of compressor wheels. Where damage is significant, MAN’s in-house laboratory is available for assessment work to confirm the feasibility of part repair.

A further service offered through MAN PrimeServ is the modernisation and upgrade of existing equipment to maximise reliability, availability and efficiency in operation. This can include upgrades of engine components but also the re-matching or full upgrade of turbochargers. As turbocharger performance has a major influence on engine power and efficiency, the retrofit of an existing engine with the latest MAN turbocharger technology can both extend operational life and significantly improve engine economic and environmental performance.

Related to this Story

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.