Business Sectors

Events

Contents

Register to read more articles.

Tug owners pushing autonomous and remote vessel tech envelope

Autonomous and remotely controlled technologies are increasingly influencing towage and tug operations, bringing efficiencies and safety benefits not previously anticipated

Artificial intelligence, machine learning and advanced computers are enabling greater levels of automation and remote operations, introducing more applications to mitigate risk from tugboat operations.

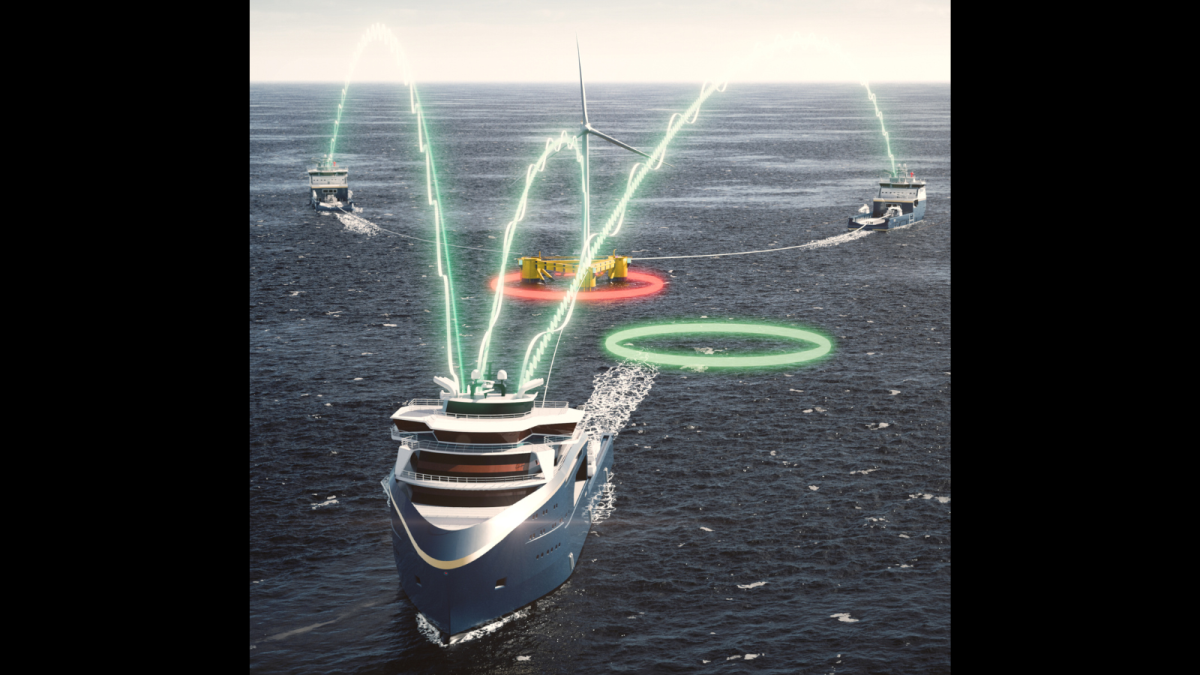

Kongsberg Maritime has developed digital technology to make towing and manoeuvring large offshore and marine construction structures more efficient by co-ordinating tugs and vessels in projects of greater complexity.

The Norwegian group has introduced Tow Assist, which uses dynamic positioning (DP) technology and operational analysis to improve situational awareness, safety and efficiency throughout all stages of the towing operation.

This builds on the K-Pos DP system, enabling unpowered floating structures to become DP-enabled during complex towing operations by calculating and distributing the optimal allocation of the connected vessels, including deepsea and harbour tugs.

Kongsberg primarily developed this technology to be used to tow huge floating wind turbines to remote offshore fields, but it can also be deployed on other large offshore and marine structures. It successfully trialled Tow Assist in the North Sea in 2024. This system provides real-time situational awareness through graphical guidance for precise and efficient towage and positioning.

Information is displayed on the lead towing vessel that can automatically command other tugs involved in towing, manoeuvring and positioning the floating offshore structure. This enables automated tows and provides insights to towage masters and vessel captains who could remain in control of the operation.

Remote control

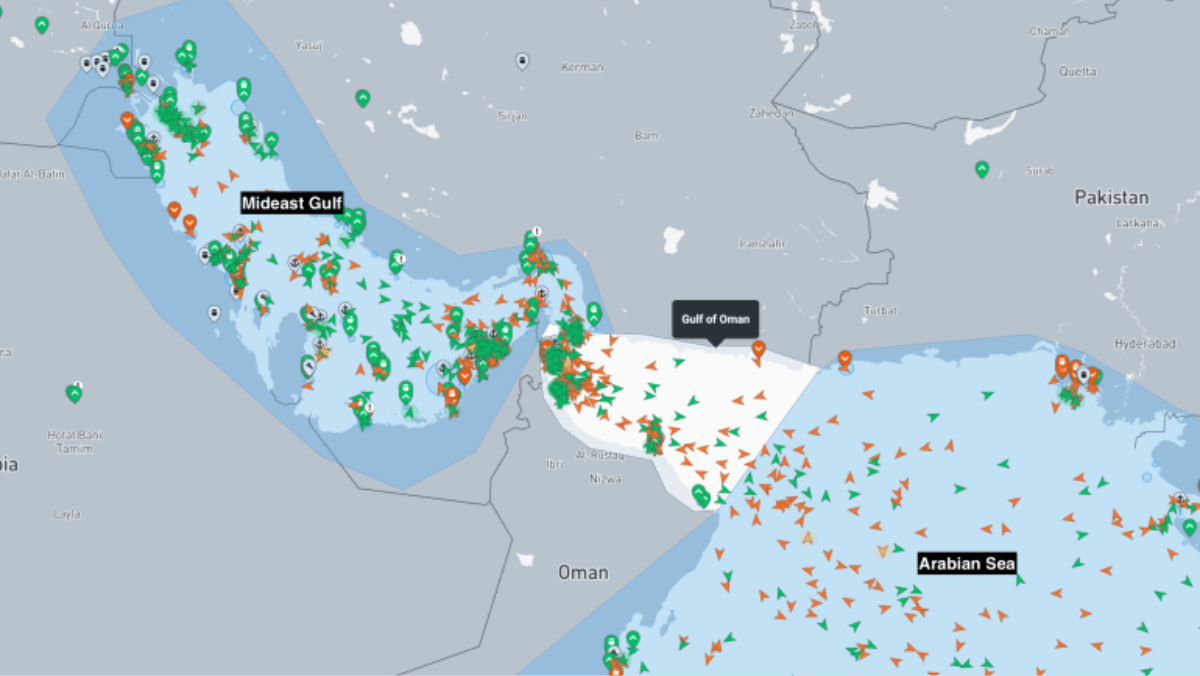

Chilean owner Ultratug is using technology to remotely operate a 32-m tugboat in Chile. MAHI’s Remote Operation solution is being used on 2010-built tug, Enco, to reduce manning in the wheelhouse during long coastal voyages to service remote ports.

Experts can remotely navigate Enco from a newly established operations centre (ROC) in Ultratug headquarters in Vina Del Mar, Chile, says Ultratug sales manager Felipe Meza Sigala.

“Commissioned in Q3 2024, the remote operation system was officially put into operation on 17 September 2024, he tells International Tug & Salvage. “This innovative project reflects Ultratug’s commitment to operational excellence and safety.”

The system includes MAHI Sense onboard computer and MAHI Bridge software to seamlessly integrate with onboard equipment such as main engines, thrusters, radar, automatic identification system (AIS) and VHF radio communications.

“The introduction of remote operation technology marks a transformative moment for Ultratug’s operations on three fronts, namely operational excellence, safety and sustainability,” says Mr Sigala. It enables the owner to maintain a single bridge complement during long-distance voyages, with the master only required for performing manoeuvres upon arrival, “thus increasing crew effectiveness by 20% and improving working conditions for crew working from the office,” he explains.

“Navigation crews working from the ROC can focus on their core tasks of navigating the vessels, avoiding idle moments and travel to and from the vessel.”

This initiative combines Ultratug’s deep operational expertise with next-generation technology to “significantly enhance the safety of crew and vessels by the automated processing of navigation sensors such as cameras, radar and AIS to detect and flag potential hazards,” says Mr Sigala.

“A third advantage of operating a crew from a centrally located ROC is the increased sustainability of Ultratug’s operations by eliminating the need to fly crew to ports for long-run vessel navigation.” He adds Ultratug is exploring potential opportunities for a broader adoption of remote operation technology across its fleet.

“We are pioneering advancements that optimise our operational performance, improve navigation efficiency and set new safety standards,” says Mr Sigala. This reduces the need to employ an additional pilot for navigation shifts and enables tugboat masters to rest during long voyages, so they remain in full compliance with work and resting hour requirements when the tug arrives at its destination.

“Ultratug has reduced its operational risks, enhanced the sustainability of its work and is at the forefront of efficient and sustainable maritime operations.”

Drone developments

Kotug International is using autonomous navigation, remote control and unmanned aerial vehicles (UAVs) to enhance safety, improve training and optimise operations on tugs and during towage.

It has developed an autonomous training tug, Rotortug Borkum for teaching, practising and assessing the navigation and towage expertise of vessel masters and maritime pilots. According to Kotug’s director of the Maritime Excellence Centre, Patrick Everts, the Dutch tug owner uses its experience to train tug masters and pilots worldwide and to promote standardised best practices through its consultancy division.

Kotug has also developed ways of using UAVs to improve towage safety. It has collaborated with technology provider Skeye to develop Tug Drone, where a UAV carries a line from a tug to an assisted vessel.

During H1 2024, Kotug and Skeye successfully executed a pilot project involving a drone transferring a line from a Kotug tug to the helideck of offshore construction support and crane vessel, Heerema’s Thialf, over 400 m.

This demonstrated using UAVs to deliver a messenger line to a predetermined location on an assisted ship, enabling Kotug to actively integrate drone capabilities into daily tug operations.

“We are pioneering drone line transfer technology and remote monitoring, which enhance operational safety and efficiency,” says Mr Everts. “We are enhancing towage operations using drones in challenging environments.”

Tug Drone delivers the messenger line directly to the assisted ship, enabling the tug to sail safely alongside rather than in front of the vessel. This can replace conventional methods where tugboat crews position themselves in front of and close to the assisted vessel to grab the heaving line by hand, placing them in the danger zone near the bow of the vessel.

“This innovation ensures safer and more controlled operations, significantly reducing the risk of accidents. including potential injuries to the deck crew and damage to both the tug and the assisted vessel,” Mr Everts adds.

In Q3 2024, Kotug deployed Tug Drone to its services supporting ExxonMobil’s deepwater energy projects offshore Guyana, where tankers are loaded with crude oil from floating production storage and offloading vessels.

Brazilian trials

Wilson Sons is testing drones in the Port of Salvador, Bahia, Brazil, to optimise the delivery of small packages and documents to ships.

It uses UAVs from Speedbird Aero to make port operations safer, more efficient and sustainable. Wilson Sons says UAVs support Brazilian port developments by introducing innovation and new technologies.

In 2022, Speedbird was the first company to obtain authorisation from Brazil’s National Civil Aviation Agency to operate aerial drones beyond visual line of sight between the pilot and the aircraft, with no auxiliary observer for long-distance flights.

“The drone tests are a milestone of innovation in Brazil’s port sector, generating even safer, more efficient and sustainable technological solutions,” says Wilson Sons executive director of shipping agency, Flávia Carvalho.

“The competent authorities have granted all authorisations and licences required for the operation, therefore Speedbird fully guarantees the safety of this activity. Safety is a value and a non-negotiable requirement for Wilson Sons.”

The Brazilian tug owner is driving innovation in the port and maritime sectors, including founding Cubo Maritime & Port in 2022. This is the first hub in the Latin American maritime and port sector dedicated to promoting an innovation ecosystem and developing new technologies.

Riviera’s TUGTECHNOLOGY ‘25 will be held in Antwerp, 22-23 May 2025. Click here for more information on this industry-leading event.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.