Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Five years into sulphur cap, cat fines still a 'major problem', says fuel test group

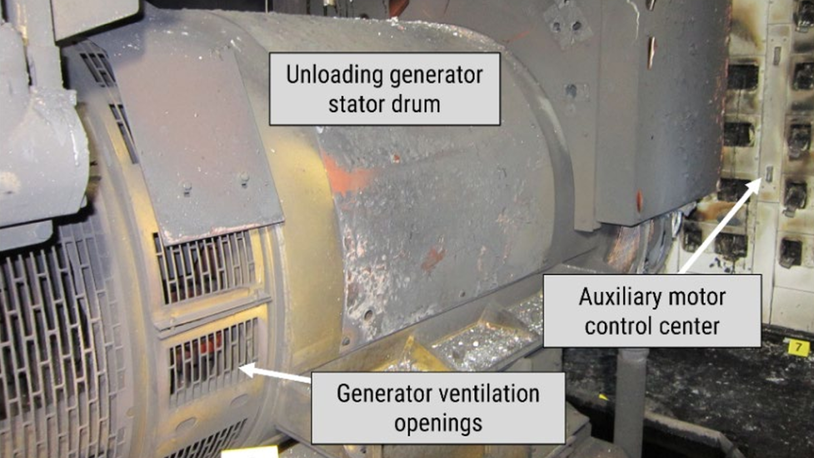

Catalytic fines made up of abrasive particles can damage engine components ’beyond repair’, according to fuel-testing specialists CM Technologies

Catalytic fines that can damage engine components are exceeding ISO standards in northern European bunker samples, according to the Germany-headquartered fuel testing specialist company CM Technologies.

A byproduct of catalysts used in fuel refining processes, catalytic fines, commonly referred to as ’cat fines’, are typically hard aluminium and silicon particles that abrade and cause wear to engine components.

CM Technologies managing director Matthias Winkler said cat fines levels are "exceeding ISO8217:2017 specifications in fuel being bunkered in some areas, including the ARA (Antwerp-Rotterdam-Amsterdam) region".

However, Mr Winkler said the more common cause of damage to engines comes from vessel operations, particularly in rough seas, that send larger levels of cat fines, that have built up in fuel tank sediment deposits, back through the engine.

"These very hard, abrasive aluminium and silicon particles... can severely damage cylinder liners, fuel injection valves, piston crowns and rings, potentially damaging the engine beyond repair," CM Technologies said.

The company suggested that using higher viscosity intermediate fuel oils (IFO), such as IFOs with a 380-centistoke (cst) viscosity or IFO 180-cst fuels, could result in more cat fines remaining suspended in the denser liquids allowing them to be more easily removed by fuel separators.

"Low-sulphur fuels have an average viscosity of 105 cst, though it can be as low as 10 cst. And this is resulting in cat fines sinking to the settling tank, where they can often [go] undetected," CM Technologies said.

CM Technologies’ report of bunker fuel tests exceeding ISO specifications comes shortly after Singapore-headquartered fuel testing centre Maritec released an industry alert saying ’several’ ships in the fuel bunkering hubs of Singapore and Rotterdam have reported operational problems after apparently bunkering fuel blended with cashew nutshell liquid (CNSL). In response, Singapore and Rotterdam port authorities have said they have received no reports of vessels with fuel-related problems.

In reply to the claim that ISO specifications were being exceeded in the ARA region, the Port of Rotterdam said "The Port of Rotterdam Authority is not involved in the quality of purchased bunkers."

Riviera has contacted the International Bunker Industry Association (IBIA) trade group, which was formed as an international forum for bunker suppliers regarding the report. Their representatives have said they are working on a response to the report.

Engine builders recommend no more than 10 parts per million (ppm) of cat fines in the fuel before it enters the engine. While some ship operators are opting for additives that can improve total sediment potential, sediment tests have shown samples significantly exceeding the maximum cat fines limit of 0.10%.

"In reality, it is about 30 ppm, but sediment levels are much higher," Mr Winkler said, noting that with low-sulphur fuels, cat fines levels in fuel before it reaches the fuel oil separators and consequently before entering the engine, is usually unknown.

CMT has found that, since January 2020, more paraffinic blends are being used, which poses a different type of danger to vessel engines and components when mixed with aromatic fuel.

"Mixing two types of fuels increases the risk of incompatibility, particularly when mixing heavy fuel and low-sulphur distillate fuels. This can result in clogged fuel filters, separators and fuel injection pumps, all of which can lead to a loss of power or even shut down of the propulsion plant, putting the ship at risk," CMT operations manager David Fuhlbrügge said.

Another outcome of fuel blending that can increase the sediment formation and fuel system blockages that CMT is seeing are increased levels of asphaltene.

Aside from the manual removal of sludge from tanks, which is both time-consuming and costly, CMT advocates the services it offers involving monitoring and testing fuels for compatibility.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.