Business Sectors

Events

Contents

Register to read more articles.

Antarctic cruise ship newbuild gets ‘fuel flexible’ MAN gensets

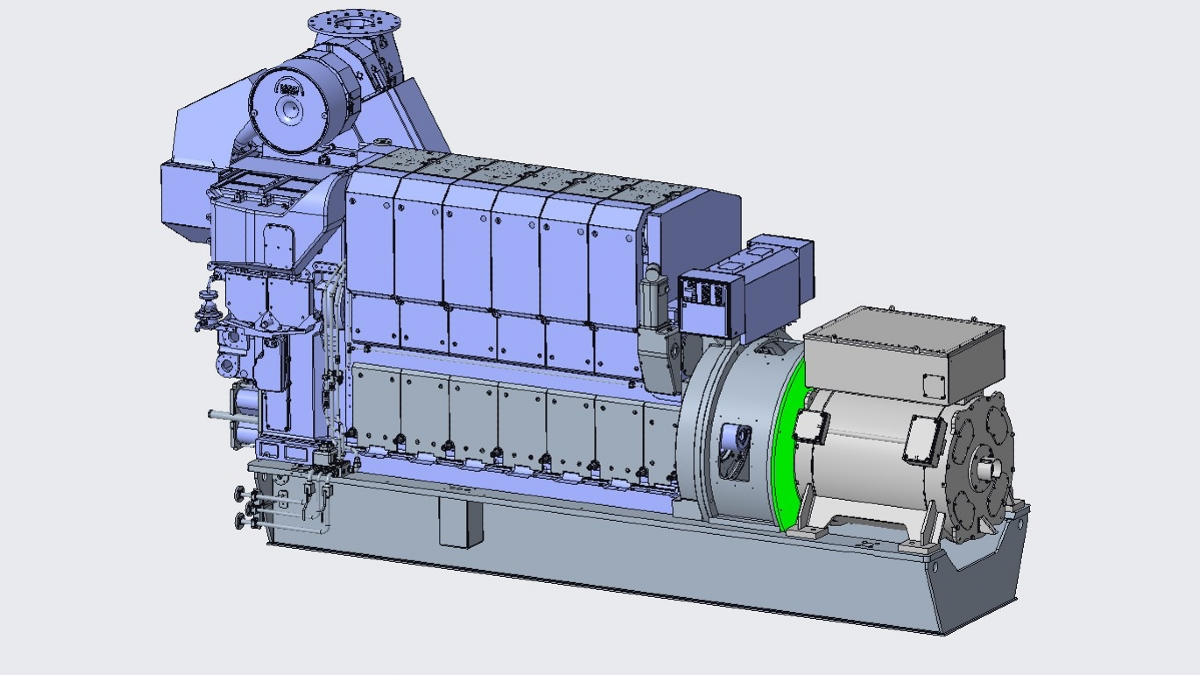

A 94-m, diesel-electric PC6 Polar ice-class cruise ship newbuild under construction in Chile will be equipped with four MAN 6L21/31 Mk2 part-load optimised (PLO) gensets

The new cruise ship is being built for Chilean tour operator, Antarctica21, which operates fly and cruise expeditions to Antarctica and sea voyages to the Falkland Islands, South Georgia and Antarctica. Called Magellan Discoverer, the cruise ship will accommodate 76 guests in 40 cabins across three passenger decks.

The operator said Magellan Discoverer is being constructed in response to the growing popularity of the company’s fly-and-cruise Antarctic expeditions, an offering they claim to have pioneered more than 20 years ago. Antarctic21 president Jaime Vásquez said the new ship was born out of customers’ rising expectations.

“Magellan Discoverer strengthens our dedication to sustainability while offering seamless comfort for our travellers. With its modern elegance and advanced technical features, it supports our ongoing effort to provide unparalleled experiences in the spectacular Antarctic region.”

Like 2019-built Magellan Explorer, Magellan Discoverer complies with the stringent Tier III emissions standard with its hybrid diesel-electric propulsion and heat recovery systems.

Chilean shipbuilder ASENAV ordered the vessel’s four MAN 6L21/31 Mk2 PLO gensets. Each genset will come integrated with MAN Energy Solutions’ proprietary low-pressure selective catalytic reduction system that delivers NOx reduction rates of up to 90% in fulfilling the latest IMO environmental requirements and is equipped with MAN’s safety and control system.

Like its predecessor, Magellan Discoverer will be build at ASENAV shipyard in Valdivia, Chile with delivery expected in December 2026. It will join the company fleet for the 2026-27 Antarctic cruise season.

Fuel flexible

Besides emissions, a strong factor in the four-stroke, small-bore genset’s selection was fuel savings. “This engine sets the standard for the lowest fuel consumption in its category,” said Antarctica21 president Jaime Vásquez.

The MAN 21/31 Mk2 PLO engine maintains a significantly reduced fuel consumption, up to 9 g/kWh at 75% MCR, with the longest times between overhaul in its class, according to the engine designer. Fuel flexibility is a benefit of the Mk2 engine, which is capable of burning conventional marine fuels like HFO/LSFO, MDO and MGO, complying with new ISO 8217:2024 fuels, as well as sustainable fuels like biodiesel FAME and HVO-100.

The 21/31 Mk2 PLO engine is designed as ‘methanol-ready’ with an approval in principle issued by class society DNV for retrofit to methanol operation in the future.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.