Business Sectors

Contents

Hartmann gas carriers log 10,000 hours on ethane fuel

Two new 36,000 m3 ethane/ethylene carriers operated by Hartmann Reederei of Germany on the transatlantic route have successfully logged 10,000 hours running on ethane in their two-stroke, high-pressure, dual-fuel engines.

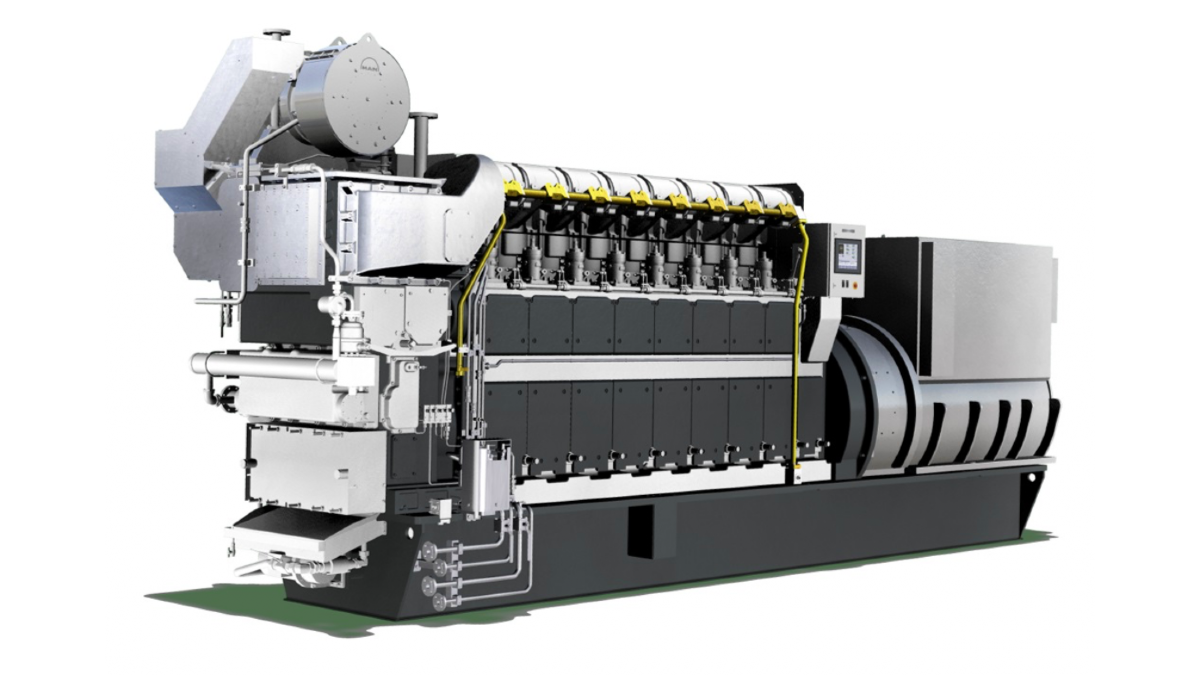

Gaschem Beluga and Gaschem Orca are powered by the world’s first M-type, electronically controlled, gas-injection ethane (ME-GIE) engines supplied by MAN Diesel & Turbo. The pair, each provided with a gas-driven 7G50ME-GIE engine, achieved their collective milestone since going into service in late 2017.

The two gas ships were ordered by Hartmann and Ocean Yield of Norway at the Sinopacific Offshore & Engineering yard in China for transporting ethane derived from US shale gas to European crackers for the production of ethylene. The vessels are on charter to Sabic Petrochemicals.

“We are grateful to MAN Diesel & Turbo for developing their natural gas ME-GI engine to burn ethane,” stated Hartmann’s fleet manager Captain Ulrich Adami. “The ME-GIE unit is very reliable and about 97-98% of our ships’ passage back and forth over the Atlantic has been on ethane. Our charterers are happy with the positive budget implications that have come with being able to exploit the fuel on board.”

He continued “You are always taking a risk with prototypes, in this case not just the engine but all the new features that were implemented into these vessels. But I was confident that we had reliable partners and we wouldn’t have any major issues, so the risk was mitigated.”

Adami concluded “Overall, the propulsion system performs very well with an even better fuel consumption than predicted, and we are recording higher sea-passage speeds during heavy weather in the Atlantic. I believe Gaschem Beluga and Gaschem Orca are among the fastest vessels on the Atlantic crossing.”

MAN Diesel & Turbo sales and promotion manager René Sejer Laursen reported “While our inspections of the cylinder liners on both sides of the Atlantic show they still look brand new, we continue to look for ways to further improve the ME-GIE’s performance. We are currently working on lowering pilot-oil consumption and expect to eventually to get it down to just 1%.”

The propulsion packages supplied by MAN Diesel & Turbo for Gaschem Beluga and Gaschem Orca also feature an AT3000 remote control system, a VBS 1350 – ODS Mk5 controllable-pitch propeller, a rudder bulb and a shaft generator with frequency converter that enables it to run at variable speeds between 80 to 100 rpm.

The engine manufacturer pointed out that combustion performance of the ME-GIE’s diesel-cycle engine, enhanced by the relatively high gas-injection pressure, enables it to operate on almost any gas quality, without any reduction in efficiency.

The engine can run on a mixture of LPG and methane, or ethane, with an unchanged gas-mode efficiency. Such a mixture may comprise as much as 50% LPG, while MAN Diesel & Turbo’s findings thus far indicate that an even greater LPG percentage can be used. MAN Diesel & Turbo contends that the negligible methane/ethane/LPG slip of the ME-GI engine makes it the most environment-friendly, two-stroke technology available.

Hartmann Reederei is also a part of the JHW consortium that ordered five 85,000 m3 very large ethane carriers (VLECs) at SOE in 2016. Each of the vessels will be powered by a single MAN B&W 6G60ME-GIE main engine. Following delivery, the vessels will go on charter to Oriental Energy of China.

Like Gaschem Beluga and Gaschem Orca, the 85,000 m3 VLECs, will be fitted with Star-Trilobe cargo tanks, a new Hartmann design which essentially combines three cylinders into one. Each ship will have four tanks and the largest, at 23,000 m3 in capacity and weighing 1,800 tonnes, will be the largest IMO Type C pressure vessel tank ever fitted on a gas carrier by a wide margin.

Related to this Story

Events

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

CO2 Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.