Business Sectors

Events

Offshore Support Journal Conference, Middle East 2025

Contents

Register to read more articles.

High demand drives tugboat newbuilding surge

Owners worldwide are ordering higher-powered vessels with lower emissions

Tug owners and shipyards are benefitting from a buoyant market for harbour and coastal towage, with more being constructed with higher bollard pulls and technologies to lower emissions.

Construction of electric tugs and those with hybrid propulsion is accelerating, with more nations and shipyards starting their own projects for low-emissions ship towage; but still the vast majority of newbuilds have twin main diesel engines driving either azimuth thrusters or fixed-pitch propellers on the stern.

More of these diesel-fuelled newbuilds have exhaust aftertreatment and selective catalytic reduction (SCR) units, removing more than three-quarters of NOx and enabling compliance with IMO Tier III emissions standards.

With more than 300 tugs built annually - 348 in 2024 according to International Tug & Salvage (ITS) data - this is a huge market for engine and thruster manufacturers and suppliers of generators, pumps, deck machinery, fire-fighting systems and wheelhouse equipment.

Construction in 2025 appears to be even higher than in 2024, with more than 180 tug and towboat deliveries, as recorded by ITS, in H1 2025. Q2 2025 was particularly active with 104 deliveries recorded. Early indications on H2 2025 activity suggests this year is heading towards a record year for tug deliveries.

There has been no rest for tug builders, as multiple fleet orders were tackled and completed from January to June this year. Of these deliveries, around 20% were from Chinese shipyards, produced for export by Damen Shipyards and Cheoy Lee Shipyards, and for domestic owners, for which Jiangsu Zhenjiang Shipyards is the most prolific. Damen’s prominent position in shipbuilding in Vietnam means this nation produced around 13% of all tugs in H1 2025, while Turkey was close behind with 12%. With several independent shipyards, Malaysia was the second-largest nation for producing tugs, with 15% of the market. Indonesia would have been in this tug producer list, but there is scarce information coming from its shipyards on new deliveries, with more of that nation’s owners turning to Malaysian and Chinese builders.

Tug and towboat construction is high in the US, which produced 11% of these vessels, almost all for its domestic market, in H1 2025. In Europe, the Netherlands and Spain are also major tugboat producers. India is returning as a builder of tugs, with Cochin group being the most prolific yard.

After Damen, three Turkish companies are the largest tug builders: Med Marine; Sanmar Shipyards; and Uzmar Shipyard. They produce fleets for major owners, mostly using Robert Allan designs such as the RAstar-series escort tugs Uzmar has built for Kotug International, of which the latest delivery was SD Chatboul. Another major operator adding to its fleet was Boluda Towage, with tugs completed for ports in Latin America, North Africa and Europe.

Winning Logistics added several tugs to its operations in Guinea, where it supports mining exports. Maritime Partners received the most towboats in the US from domestic shipyards.

“We are talking with ports about getting shore power for electric tugs”

Other companies adding several tugboats to their fleets in H1 2025 were Camorim, P&O Maritime Logistics, PSA Marine, SAAM Towage and Svitzer.

On the ordering side, data is harder to obtain, so this does not match the deliveries information. However, ITS recorded 53 newbuild contracts in Q2 2025 compared with just 26 in Q1 2025, but 52 in Q2 2024. These orders were dominated by shipyards in China, Turkey and Vietnam, with a few orders in Malaysia, India, the US and the Netherlands.

These contracts and many other unreported orders boosted the global orderbook for tugs to 406 at the beginning of July, according to BRL Shipping Consultants, its highest since ITS began reporting this data in 2018.

Battery revolution

A notable number of tugs were built with energy storage systems (ESS) on board. This is becoming a new trend, as tug owners see the environmental advantages of having battery-powered tugs in their fleets operating in ports where there is charging infrastructure.

To date, 42 tugboats, pusher vessels and towboats operate with ESS on board, either providing full power for propulsion or as part of a hybrid-electric configuration, according to information collated by ITS. Of these, nine were completed and delivered in H1 2025, and 12 were delivered in 2024. Another 10 electric-powered tugs and pusher vessels could be completed by 31 December 2025.

Turkey remains the biggest building nation for battery-powered tugboats, but China is building up experience in constructing these vessels. Damen Shipyards in Vietnam has produced several electric tugs, with these vessels operating in New Zealand, Belgium and the United Arab Emirates (UAE).

Other nations producing electric-powered tugs include Japan, South Korea, India, the Netherlands and the US, while Brazil has built hybrid-electric pusher vessels and Spain has completed tugs with hybrid propulsion.

China now has the most operating electric tugboats, at eight, as the nation’s ports seek to reduce emissions in harbours and river estuaries; while there are five operating in British Columbia, western Canada.

They will be overtaken by Panama in the next two years, as the Panama Canal Authority has ordered 10 tugboats with hybrid-electric propulsion from Armon Shipyards in Spain and has confirmed an option for another 10 of these vessels. Of these, three have been completed, with Isla Barro Colorado in Cristobal, Isla Bastimentos in Pena Blanca, Panama and Isla Bona undergoing sea trials in Gijon, Spain according to automatic identification system (AIS) data.

These 29-m tractor tugs have a beam of 14 m and a maximum draught of just over 6 m, and two diesel main engines, each with 2,331 kW of power, supported by a 445-kW battery pack, which is small for an ESS, to drive two thrusters and generate a bollard pull of 80 tonnes. Hybrid propulsion reduces the amount of CO2 emitted during transits and mobilisations and increases the available power for ship handling and towage. These tugs also have a FiFi1 system for fighting fires and enhanced accommodation for crew.

In comparison, ElectRA design tugs built by Sanmar Shipyards for several owners have more than 3,600 kWh of battery capacity for zero-emissions ship towage in harbours.

Alternative fuels

The towage market is also preparing to use future fuels, with some tugs built with dual-fuel engines to combust methanol, LNG, ammonia and hydrogen, or with fuel cells. For example,

Sanmar Shipyards has built two methanol-powered escort tugs for Kotug Canada, with the first scheduled for launch soon. These 44-m tugs, SD Aisemaht and SD Qwiy Aanitsa Sarah are constructed to a Robert Allan Ltd RASalvor 4400-DFM design, with around 120 tonnes of bollard pull. Equipped with twin methanol dual-fuel engines, they feature Schottel’s Sydrive-M mechanical hybrid propulsion, consisting of two azimuth rudderpropellers of type SRP 710 that can be driven by just one of the two high-speed main engines on each tug.

“Dual-fuel engines enable longer operations with lower emissions”

When completed and operating in western Canada, these tugs will escort laden crude oil tankers from the outer harbour limits of the Port of Vancouver to the open Pacific Ocean through the commercial shipping lanes of the Salish Sea, where they will also provide emergency response.

For Svitzer, Uzmar is building a TRAnsverse-design tug with methanol dual-fuel engines and around 6 MWh of battery capacity. Construction of this TRAnsverse 3500E design tug is expected to be completed in 2026, says Uzmar Shipyard project manager, Furkan Yildiz.

“The dual-fuel engines enable longer operations with lower greenhouse gas emissions, while the batteries provide close to zero emissions,” he explains. “This is operational flexibility and fuel efficiency in one vessel. System integration is important, and hybrid propulsion has many benefits.”

This 35-m, ABS-class tug will have a beam of 15 m, twin methanol dual-fuel engines and two rooms each with 3 MWh of batteries, all combined to generate 85 tonnes of bollard pull.

Mr Yildiz expects more methanol-battery tugboats to be ordered and brought into service.

“We are crafting a blueprint for the future of green sustainable towage,” he explains, adding the TRAnsverse 3500 E is “a crucial milestone to lowering emissions” and lowering the towage industry’s carbon footprint.

Global operator

Svitzer is the leader in using biofuels in tugboats, outside of Indonesia where it is mandatory to use diesel-biofuel blends from palm oil. A considerable amount of tugs in Svitzer’s UK fleet operate on hydrogenated vegetable oil (HVO) and the Danish owner is testing the use of fatty acid methyl ester (FAME) fuels in the Netherlands and Oman. Svitzer offers EcoTow to global shipping lines and has teamed up with DP World in the UK to provide lower Scope 3 emissions to owners and operators.

Svitzer added the first fully electric tugboat to its fleet in July after Sanmar Shipyards built it at its facilities in Altinova, Turkey. This 25-m, battery-powered vessel was built to Robert Allan’s ElectRA 2500SX design, with a 13-m beam and a draught of 5 m.

“We are focusing on reducing our carbon emissions footprint and thereby supporting the decarbonisation of the maritime industry,” says Svitzer chief operating officer, Kasper Karlsen.

“We believe electric tugs are key to achieving our ambitions of net zero,” he adds. “With this new tug, we are taking steps towards electrifying our fleet.” This ABS-class tug has a battery capacity of 1,808 kWh from Corvus Energy, backed up by generators to drive two Schottel azimuth thrusters, and a FiFi1 fire-fighting capability, while achieving a bollard pull of 70 tonnes.

It is part of an ElectRA series of battery-electric tugs Sanmar is building for several owners and its own fleet. These are being built in a range of 19 m to 28 m long, with power outputs ranging from 40 to 85 tonnes of bollard pull. Sanmar has completed 10 fully electric tugboats to date, with five more currently under construction.

Svitzer chief operating officer, Kasper Karlsen, says the biggest challenges in lowering port emissions include supplying electric power to tugs while they are at berth, which would enable battery-powered vessels to be used in ports.

“We are talking with ports about getting shore power for electric tugs, but this is challenging,” he says. “Another big challenge is getting charterers on side.”

Mr Karlsen suggests ports could install microgrids and generate power from renewable resources and store it in quayside batteries. Svitzer would not be interested in operating microgrids, but could use them, “depending on the ownership structure and where they are installed,” he adds.

“Microgrids can be difficult to justify, but with battery storage on quays, they could support the transition and provide financial benefits. Grid energy prices could provide business opportunities for ports,” he says.

Future Svitzer tugs will be built to its TRAnsverse design and could have combined methanol dual-fuel engines and batteries, says Mr Karlsen. “We want to drive the energy transition. Owners want sustainable financial outcomes, and solutions need to be viable, simple and cost-effective for the lifetime of our tugs,” he says. He wants to see capital and operational costs fall for low-emissions technologies and a greater availability of transition fuels.

Testing alternative fuels

As new fuels are sought, Port of Antwerp-Bruges has led the sector in its experience with them. It has been operating the world’s first tugboat operating on hydrogen, CMB.TECH’s Hydrotug, methanol-fuelled tugboat, Methatug, and one of the first battery-electric tugs in Europe, Volta 1.

Hydrotug is a 30-m, 496-gt tug with 65 tonnes of bollard pull coming from two dual-fuel BeHydro V12 engines, producing a combined 4,100 kW of power to drive two Schottel SRP 460 type Z drives. These are linked to diesel filters and SCR units to minimise NOx emissions to comply with IMO Tier III and EU stage V emissions regulations. Hydrotug has enough compressed hydrogen fuel, stored in pressurised bottles on deck, for a day’s operations before new fuel is needed.

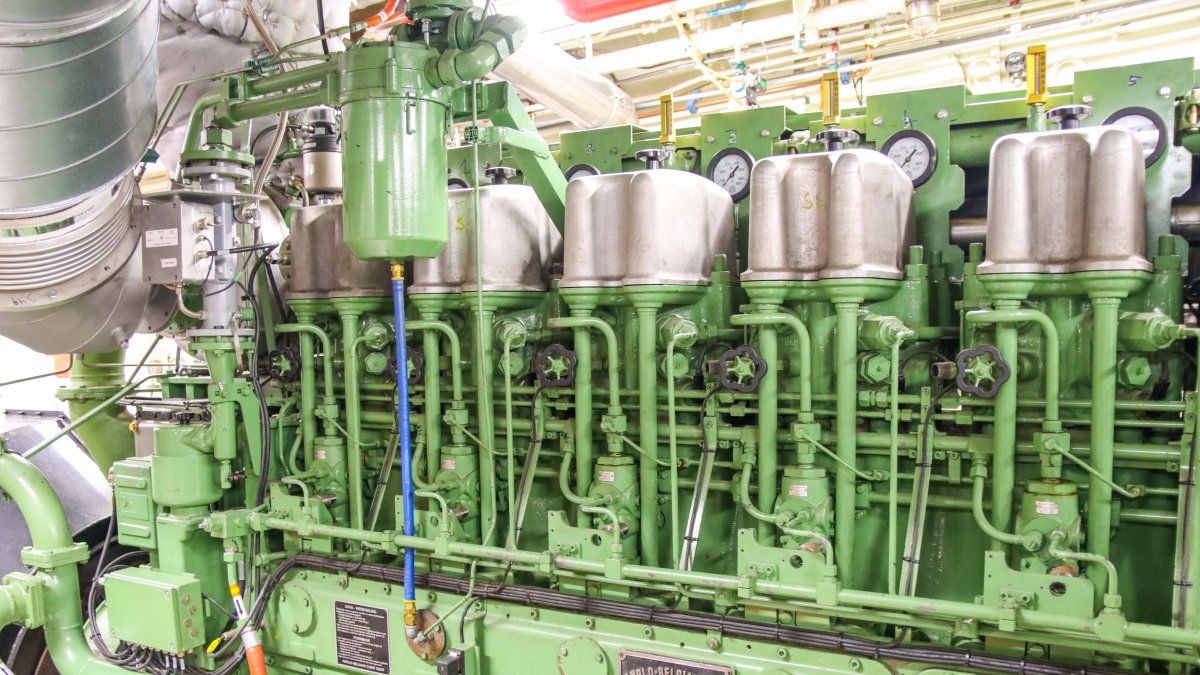

Methatug (ex-tug 21) has an overall length of 30 m and a traction force of 50 tonnes. It was converted to store and combust methanol in retrofitted Anglo Belgian Corp dual-fuel engines under the EU-funded Fastwater project in 2024.

Middle East leader

Abu Dhabi Ports Group subsidiary, Noatum Maritime, is building its fleet of electric tugboats to provide zero-emissions handling, towage and docking of ships at its Khalifa Port in the UAE.

Damen Shipyards has supplied two of its electric-powered reverse stern drive (RSD) tugboats to the port. The first of these, Bu Tinah, broke the Guinness World Record as the most powerful electric tugboat in the world in Q4 2024 during its sea trials, having achieved an average high-peak bollard pull of 78 tonnes.

This was followed by Bu Tinah 2 in Q3 2025, with both built to Damen’s RSD Tug 2513-E design and classed by Bureau Veritas, with an overall length of around 25 m, a beam of 13 m and a draught of around 6 m.

This is similar to other electric tugs Damen has built in Vietnam, with the first tugboat Sparky, working in Auckland, New Zealand for the past three years, and Volta 1 operating in Antwerp, Belgium.

Noatum Maritime director of commercial and business development in marine services, Ferlin Brown, says Abu Dhabi Ports has invested in infrastructure for charging tugs, installing a transformer, charging station and cables. “The economics work, and we are investing in supplying electric power to ships at berth,” he says. “We are creating a complete ecosystem and looking at more international opportunities.” He thinks ports should provide more shoreside power for sustainability.

In June, Damen-built electric tug Aqua Pollux was in Southampton, becoming the first battery electric tug active in the UK. It had been operating in the Benelux countries since its arrival in November 2024, where a port authority had provisionally booked it. But according to Damen sales manager for Benelux, Joost van der Weiden, Aqua Pollux is being operated by a Damen crew and is available for purchase. He says there has been interest in northern Europe, but there are challenges in finding charging stations for battery-powered tugs, which means Aqua Pollux uses its onboard Caterpillar gensets to charge its batteries. According to AIS data, Aqua Pollux was stationed in Rotterdam, the Netherlands, in September.

Inland waterways

Kotug International has developed its own battery-electric concept for pusher tugboats operating in inland waterways and has picked up orders for these in northern Europe. E-pushers come in three sizes, depending on power requirements and the width of the canals they operate within.

Kotug International director of Kotug OptiPort, training and consultancy, Patrick Everts, says these electric pusher tugs are ready to run on alternative fuels if charging infrastructure is not in place. He also thinks harbour tugs should be fuel-flexible, enabling owners to replace engines in future retrofits.

“The challenge for owners, shipyards and suppliers is how to build an asset that will last 20 years and could be retrofitted later for different fuels and propulsion systems,” says Mr Everts. “Suppliers need to adapt to those changes as we need more flexible assets running on different fuels for 30 years.”

Kotug’s first E-Pusher, built in 2023, transports cocoa beans for Cargill from Amsterdam to Zaandam, making up to three return trips on a full charge of the 2-MWh capacity batteries. When at Cargill’s facilities in Zaandam, the Octopus container is charged three times a week with energy from renewable sources.

E-Pusher tugboats are being built and operated in the Netherlands for other operators, transporting bulk cargo on barges. One is working for Ofi, transporting cocoa on four barges between Amsterdam and Ofi’s Koog aan de Zaan and Wormer factories.

Dutch sand transport group ROS is also starting a fully electric E-Pusher to handle barges provided by Jansma Shipping for an emissions-free transport chain between the Maasvlakte and Rotterdam.

Padmos Shipyard in the Netherlands builds E-Pusher vessels for Kotug, while Jansma Shipyard retrofits barges. EST-Floattech works with Kotug, Sea and Shore and Gebhard Electro to design and customise containerised Octopus ESS to power the propulsion and auxiliary systems.

Hydromaster Propulsion has supplied two 300-kW electric-driven outboard azimuth thrusters for each of Kotug’s E-Pusher tugboats, with three sets already delivered. Earlier this year, it received a follow-up order for electric-driven thrusters from Kotug for an even larger E-Pusher design.

Scarcity of secondhand tugs

Environmental requirements and high demand are affecting tug availability and pricing, reducing opportunities for fleet purchases and older asset sales. There is a shortage of available secondhand tonnage as owners are reluctant to sell vessels due to high returns, while those available require high-cost upgrades.

According to Marcon International, the number of tugs available for sale at the end of Q2 2025 had dropped again to just 218, down 10% from 244 a year ago and by 64% from 605 tugs five years ago.

“Owners of tonnage are holding prices higher than this market will absorb,” says the US shipbroking firm in its latest report. “Shipyard costs continue to be very strong and inflationary pressures on this industrial segment will continue to increase.”

Marcon says another issue for owners seeking to purchase older tonnage is whether to invest in repower projects to upgrade tugboat enginerooms with modern, more-efficient engines. “Few buyers are willing to spend or exceed US$1M for tugs requiring major repowering, or major refurbishment,” it says.

Environmental regulations are affecting sale and purchase activity. Owners are renewing fleets with newbuilds while keeping older vessels within their fleets and seeking retrofit options.

“While repowering remains cost-prohibitive for many, larger operators with healthier capital positions are investing in newbuilds and major overhauls to align with decarbonisation goals,” says Marcon. “The industry continues to see strong interest in cleaner propulsion technologies.”

Offshore drives tug orders

The introduction of more floating production storage and offloading (FPSO) projects in west Africa and north-east Latin America is propelling owners to invest in newbuild escort-class tugs.

Smit Lamnalco has ordered four powerful DP-2-class, offshore support tugs from Turkey’s Uzmar Shipyard to support a new multi-year contract to provide ExxonMobil with offshore terminal support services in Guyana.

Four 60-m newbuild vessels will support FPSO activities, including operational, maintenance and logistics in the Stabroek block, some 110 nautical miles offshore.

Based on Robert Allan’s RAmpage 6000-DE design, each tug will have a bollard pull ahead exceeding 130 tonnes and astern of 120 tonnes and have FiFi1 fire-fighting capabilities and equipment for emergency response. They should be delivered in early 2028. ExxonMobil operates four FPSOs in the block and has plans for at least two more.

Kotug has added five Uzmar-built escort tugs to its fleet, constructed to Robert Allan’s RAstar 3200-W design, with 80 tonnes of bollard pull to support LNG export projects in Africa.

SD Djoudj, SD Chatboul, SD Rosso and SD Waalo have left the shipyard to support BP’s Greater Tortue Ahmeyim (GTA) gas project, on the Mauritania and Senegal maritime border, while SD Wonder operates from Pointe Noire in Congo for Eni’s Congo gas project, according to AIS. Kotug and Edison Chouest also support tanker loadings at ExxonMobil’s FPSOs in Guyana.

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

Maritime Decarbonization Conference, Americas 2026

Offshore Wind Journal Conference 2026

© 2024 Riviera Maritime Media Ltd.