Business Sectors

Contents

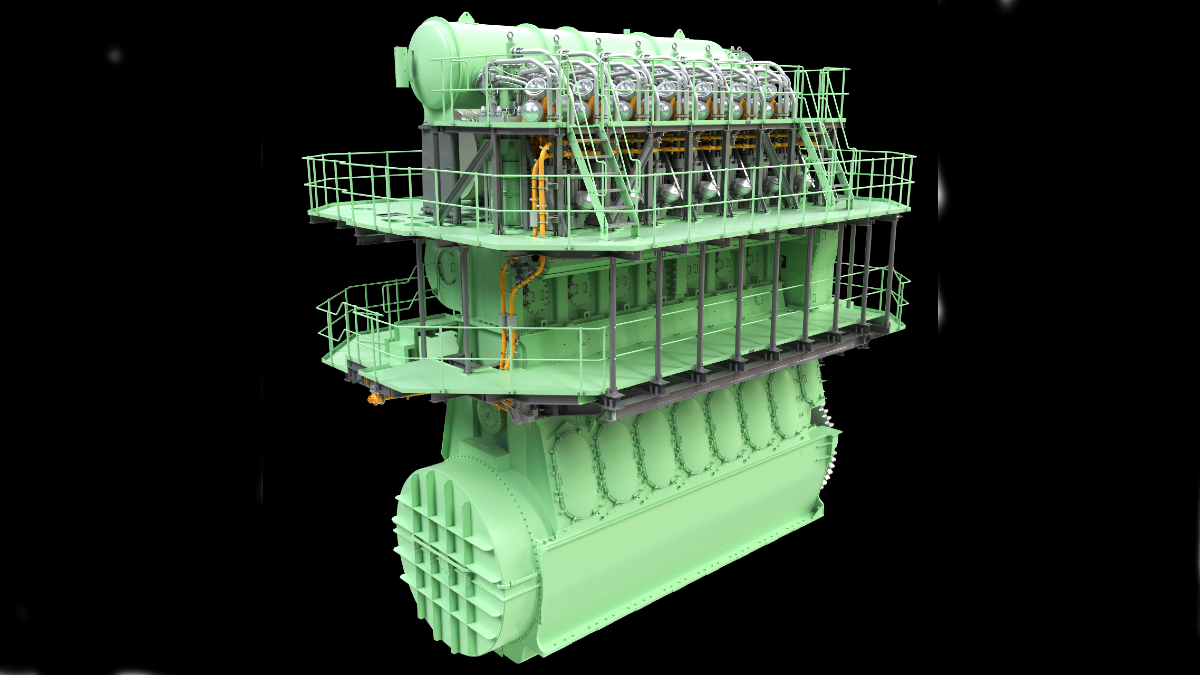

Preparing for IMO’s new engine emissions rules

A major change in emissions regulations is coming, which will likely have a considerable impact on tug and workboat design, construction and operation

There is less than five months to go before a major change in emissions regulations has a significant impact on the tug and workboat sector.

From January 2021, IMO Tier III regulations for commercial vessels with diesel engines will come into force. This imposes rules on the emissions from diesel engines on vessels with a total power of more than 130 kW, and with their keel laying date after 1 January 2021.

Vessels built after this date will need cleaner diesel engines and after-treatment systems to minimise nitrogen, sulphur oxide and particulate matter emissions.

This could lead to a rush to order new tugs and workboats before that date if owners want to avoid this restricting ruling. It is already in the minds of some tug and workboat builders, as they produce vessels that can be retrofitted with emissions-abatement technology.

Builders and naval architects have now developed designs with additional space in their enginerooms to install selective catalytic reduction (SCR) equipment for removing NOx and particulates from diesel emissions, ready for the Tier III requirements.

“US tug owners are ahead of the curve, with more vessels built to US Environmental Protection Agency’s Tier 4 emissions requirements”

Neptune Marine has worked with engine manufacturers to develop its portfolio in compliance with the upcoming environmental regulations.

Damen Shipyards is already producing tugs for its clients that incorporate space for retrofits and Robert Allan designs can also be used to build tugs to IMO Tier III requirements.

US tug owners are ahead of the curve, with more vessels built in their nation’s shipyards to US Environmental Protection Agency’s Tier 4 emissions requirements, which are similar to IMO Tier III.

Some owners in Europe now have tugs on order that will comply with IMO Tier III requirements when they are delivered.

P&O Maritime Logistics has ordered a harbour tug to comply with IMO Tier III to support container ships berthing at Barcelona, Spain. P&O Maritime Logistics chief executive Martin Helweg said this tug is under construction at DP World’s Drydocks World in Dubai for delivery in Q4 2020. “We have developed an innovative tug concept for our operations in Spain,” he said.

This eco-silent tractor tug will have a pair of diesel engines with SCR exhaust-gas emissions after-treatment systems to comply with IMO Tier III. This is an asymmetric tractor tug ATT 2020 designed by Cintranaval Ship Design.

While engine manufacturers are ready with SCR additions to their diesel main engines, one manufacturer has developed engine technology that does not require SCR to comply with IMO Tier III.

Wabtec subsidiary GE Transportation has introduced an alternative approach to reduce NOx emissions for compliance with IMO Tier III and EPA Tier 4.

It uses exhaust gas recirculation (EGR) and two-stage turbochargers on its medium-speed engines to reduce NOx without compromising on fuel efficiency.

Some owners are retrofitting existing tugs to IMO Tier III requirements. Boluda Towage Europe will retrofit tug enginerooms to comply with these emissions standards after securing a concession from the Port of Zeebrugge.

This owner upgraded Union Koala tug to IMO Tier III standards in 2019 and will retrofit Union Panda this year. In total, it will upgrade engineroom systems on six more tugboats over the next five years as part of the arrangement with the port operator.

As such, emissions of nitrogen oxides will be reduced by 80% from this tug fleet. Shore power will also become the norm for moored tugboats, so these can switch off their engines when inactive and during the rest-period of the crew.

Related to this Story

Events

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.