Business Sectors

Contents

Register to read more articles.

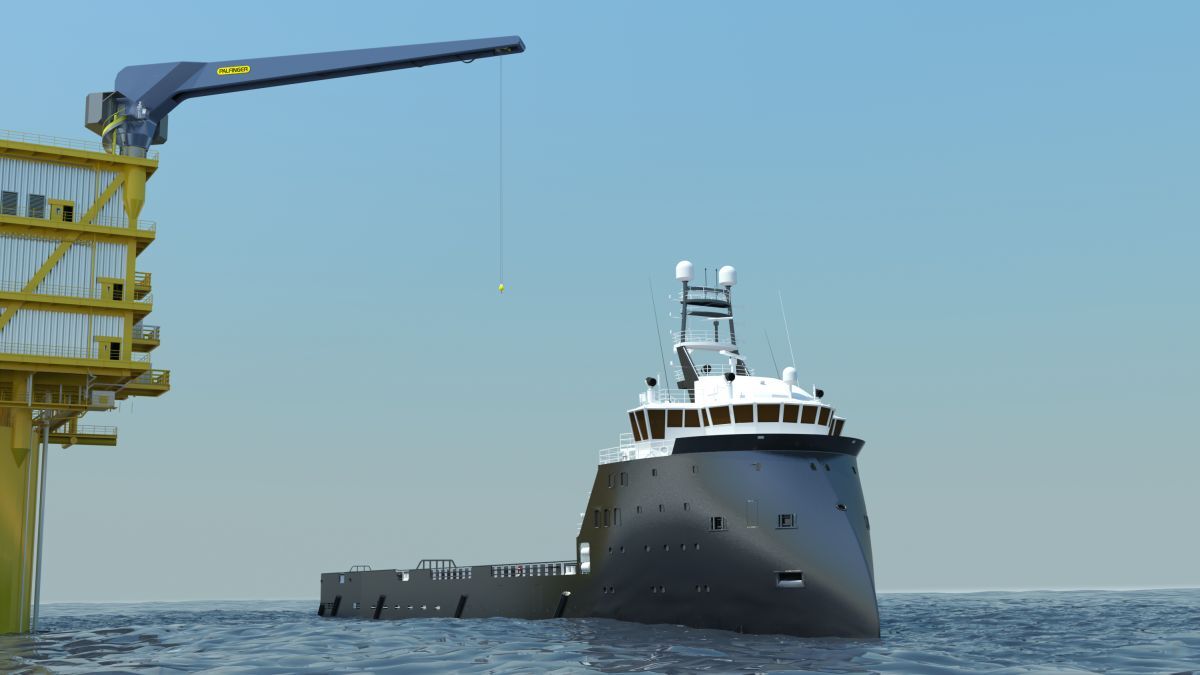

Remote-controlled cranes will take crew out of harm’s way

In an industry first, Palfinger and Aker BP will deploy cranes on offshore platforms that will be controlled remotely from onshore, keeping crew safe, while generating cost savings

Capable of operating in extremely hostile weather with waves of up to 6 m, Palfinger Marine’s latest generation of remotely controlled cranes will be deployed on Aker BP’s Fulla fields off Norway in a world first, offering significant opex savings and an important step forward in health and safety.

When the platforms come into operation – FID is due this year — it will mark the first time an oil and gas installation will be able to use cranes that are worked from an onshore control room, relying solely on camera and artificial intelligence, the Austrian-based group tells OSJ.

“It will be possible to offload a supply vessel without having personnel on the deck of the vessel,” Palfinger’s designers explain. “Nor will there be any need to have crew on board the installation or operators in the crane’s cabin.”

As a result, the crews’ health and safety is greatly enhanced. As Palfinger points out, one of the biggest dangers, especially in bad weather, comes when deck personnel connect and unhook the load. “This is a situation where a lot of injuries happen, especially to hands and feet,” the crane’s designers say.

“It will be possible to offload a supply vessel without having personnel on the deck”

Savings in transportation costs also look promising. As well as not requiring on-deck personnel, it will not be necessary for crews to be helicoptered onto the rig to operate the crane, another important contribution to safety and the bottom line. The fields are located on the Norwegian Continental Shelf, where extreme weather conditions can sometimes prevail.

Overall, Palfinger expects “huge cost savings”, particularly for operations that usually require calm weather, large crews and facilities, or highly repetitive tasks that can now be performed remotely with digital tools.

Palfinger and Aker BP have collaborated for years in the energy group’s pursuit of remote working, standardisation and automation. As the oil group’s senior vice president of operations and asset development, Ine Dove, notes: “By standardising cranes across these development projects, we can also improve quality and reduce costs.”

Palfinger first began working on remotely operated offshore cranes in 2017 in conjunction with Aker BP and Optilift, a specialist in cargo-handling in remote and harsh locations.

The collaboration is bearing fruit in other ways. Palfinger is also contracted to deliver a completely new jib crane – model number DKJ1600e – which is intended for unmanned or low-manned installations. The model is designed for intermittent use in the most remote rigs – “it can be out of operation for a long time with a minimum of maintenance requirements”, the crane-builder says.

The latest contract with Aker BP, which follows the recent delivery of four offshore cranes to the energy group’s Valhall platform, is a framework 10-year deal with an option to extend. Overall, it covers the development and implementation of remote-control cranes, plus the delivery of six electric cranes to four platforms.

Related to this Story

Events

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

CO2 Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.