Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

How batteries, gensets and data help reduce OSV emissions

Installing batteries, variable speed generators, software and data analytics helps owners to reduce fuel consumption and emissions

Decarbonisation in the offshore support vessel (OSV) sector is progressing steadily.

Newbuild OSVs have batteries, and efficient generators and engines on board, cutting their environmental footprint, and many vessels have been optimised using data analytics.

Strategies and technologies for reducing emissions from OSVs were presented at Riviera’s Annual Offshore Support Journal Conference in London, UK, on 3 February 2026.

International Support Vessel Owners’ Association (ISOA) secretary Jan-Piet Baars said the industry is working with supply chain partners to install energy storage systems (ESS) and other packages for cutting emissions.

"Decarbonisation is a work in progress," he said. "It is a key objective for owners and charterers."

ISOA is working across the industry to establish frameworks and to standardise data exchange, reporting and sharing technology information.

DNV Maritime global segment director for OSVs and special ships Arnstein Eknes said many vessel owners are using high levels of data-driven intelligence for efficient operations.

"Operating smarter does not need to cost anything, but it is good to invest in data collation and analysis," he said.

Owners have installed ESS modules on more than 300 OSVs for battery-centred hybrid propulsion and dynamic positioning (DP), especially on vessels operating around offshore windfarms.

"The energy industry is in real transformation," he said. "The industry has learned to operate with more complexity and more systems integration. Alternative fuels come next, but the challenge is which ones."

The next technology shifts include deploying offshore charging stations for vessels at windfarms and installing engines and generators ready for using alternative fuels, said Mr Eknes, adding "zero emissions is possible."

Developments in variable-speed gensets and alternative fuels are providing back-up and additional power for battery-electric vessels.

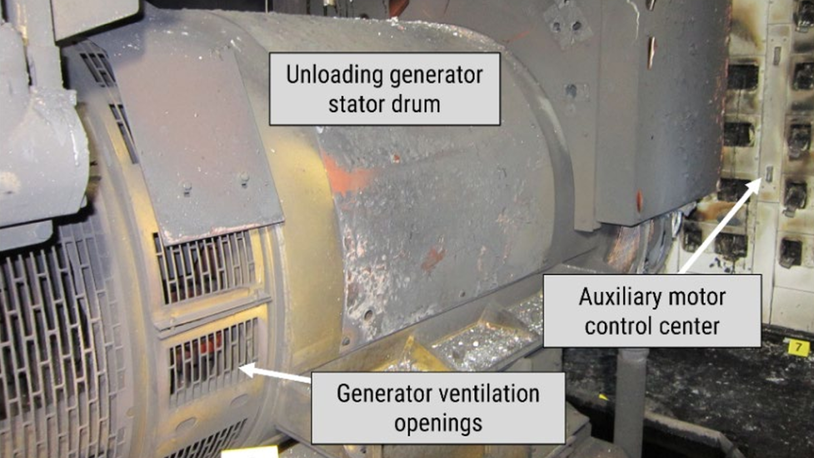

Combining ESS, direct current (DC) grids and variable-speed gensets is enabling more OSVs to reduce emissions during DP without impacting safety.

"With vessels on DP, low loads on gensets mean they can operate with less fuel consumption, noise and vibration, and there are longer periods between maintenance," said Rolls-Royce Solutions senior expert for the commercial marine business unit, Phil Kordic.

He said lightweight, compact and fuel-efficient gensets can support vessel electrification and offered a walk-to-work OSV as an example.

One of the company’s references is a Kongsberg-designed windfarm commissioning and service operations vessel with a DC Grid, 8,700 kW of genset power and space for a future ESS installation.

"These gensets provide the main source of power and hotel load and are used for DP and low-load operations," said Mr Kordic.

This vessel has three mtu 20V/4000 M65L gensets linked to an aftertreatment system for IMO Tier III compliance and heat recovery from the engines. Each genset has 2,900 kWe, generating at 30-60 Hz, and can work at variable speeds, operating between 900 and 1,800 rpm.

Data solutions

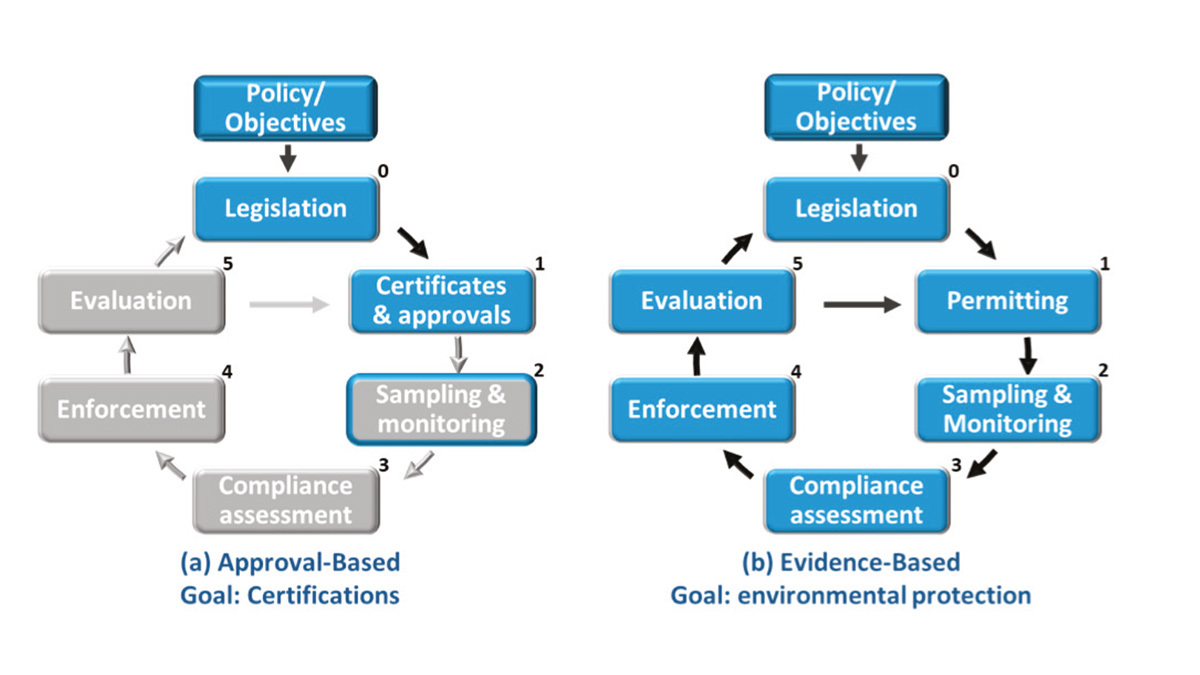

VPS chief operations officer for digital and decarbonisation, Jan Wilhelmsson, said OSV owners will need to install Emsys emissions monitoring units in the future to take exhaust samples on vessel stacks to provide information on emitted gases, including methane from gas engines, to charterers and regulators.

This will be required in Brazil for newbuilds and chartered vessels when charters are renewed, he said.

Owners are already investing in fuel consumption and emissions monitoring through data analytics, with more than 700 OSVs globally using VPS Maress software.

Maress "connects with an offshore ecosystem" connecting charterers and owners and "creates a data-driven truth for benchmarking" with data collected and then collated into a cloud-based resource that is then analysed for operational insights, said Mr Wilhelmsson.

One area where owners and charterers can work together is determining why vessels are over-consuming fuel during various operations and environmental conditions.

"It is critical to show what overconsumption is due to sea and weather conditions," said Spinergie co-founder and chief executive Jean Cristofari.

The next step is to calculate what additional fuel is consumed due to charterer requests, such as ordering vessels to transit at high speeds between jobs or having vessels waiting on standby on DP inside the 500-m zone when they could be moored outside that area.

"These would mean suboptimal engine or genset loads and higher fuel consumption," said Mr Cristofari. "Owners should go back to the charterer to show them these orders."

Technical performance is the next area to consider for fuel efficiency, especially deciding when to drydock for hull and propulsion cleaning and recoating.

Information can also be used to "highlight to crew ways to improve efficiency over time" and "show how actions are being taken and the baseline is improving," said Mr Cristofari.

Riviera’s Offshore Support Journal Conference, Asia will be held in Singapore on 8-9 September 2026. Use this link for more information and to register for the event.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.