Business Sectors

Events

Contents

Register to read more articles.

Ammonia milestone: MAN ES successfully tests two-stroke engine at 100% load

Danish engine designer tests full-scale ammonia dual-fuel engine at 100% engine load, advancing the technology towards commercialisation

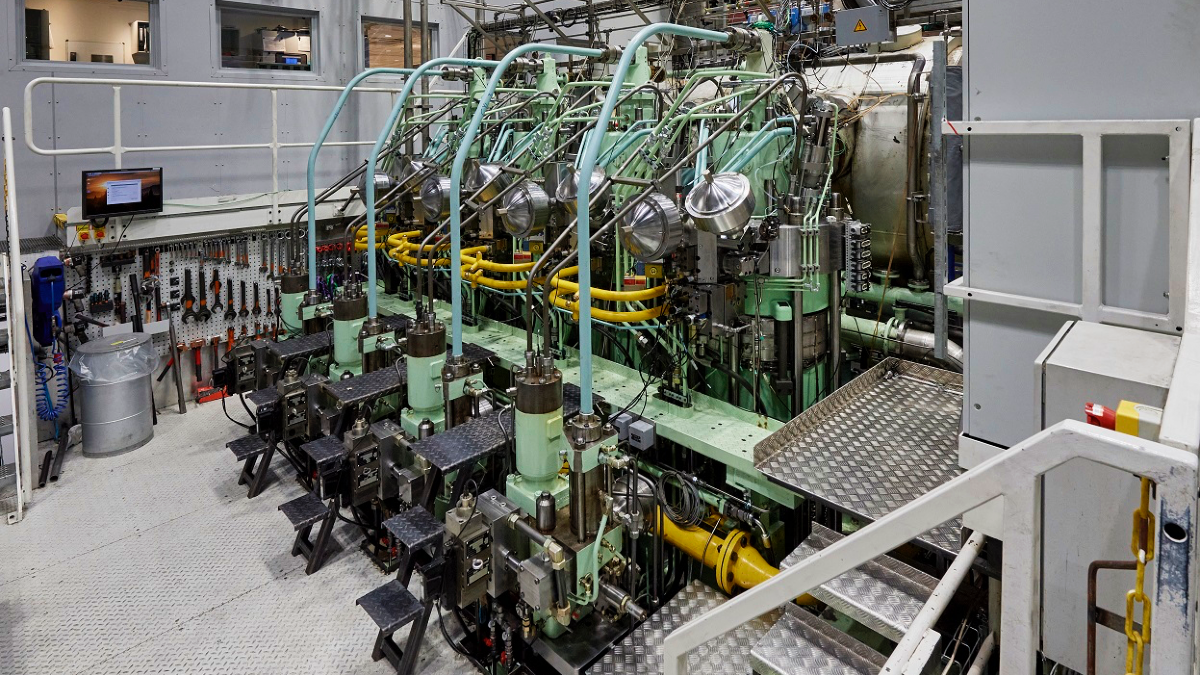

MAN Energy Solutions’ two-stroke ME-LGIA liquid gas injection ammonia engine has achieved a milestone, achieving a 100% engine load for the first time during testing at its Research Centre Copenhagen facility.

Progress on releasing the first two-stroke ammonia dual-fuel engine has “proceeded in a cautious and safety-first way,” said MAN Energy Solutions (MAN ES) head of two-stroke research and development, Ole Pyndt Hansen. Since full-scale testing began in November, Mr Hansen said the engine has been operated on ammonia from 25–100% load. “As such, we have now validated the ammonia fuel-injection system over the full load-curve with diesel-pilot amounts recorded according to our targets. Furthermore, the positive emissions and performance characteristics from previous, single-cylinder tests have now also been validated in full-scale engine operation,” he observed.

Ammonia, a zero-carbon fuel, is seen as a potential alternative fuel for shipping, replacing fossil fuels to allow the sector to lower CO2 and greenhouse gas (GHG) emissions. But ammonia, NH3, has vastly different combustion characteristics than traditional marine fuels, and is highly corrosive and toxic, requiring stringent safety protocols. Additionally, combustion of ammonia has the potential to emit harmful nitrogen oxides – a powerful GHG – requiring the use of selective catalytic reduction (SCR).

MAN ES reported its SCR “was operational at all test loads to treat exhaust gases, and that all supply and safety systems worked as intended.” The next steps in the testing will be to focus on performance and emissions optimisation, including injection and SCR systems as well as control strategies.

MAN ES head of global sales and promotion, two-stroke business, Christian Ludwig, noted the inherent design of the ME-LGIA – built on the Diesel-cycle combustion principle – makes it well suited for power takeoff (PTO) applications. “Prior to this round of testing, we simulated PTO on the ammonia engine with very positive results and are very happy to see this replicated in real life. We intend to support PTO on the ME-LGIA to the same degree as with the other Diesel-cycle engines in our low-speed portfolio.”

Using a PTO can help reduce fuel consumption, lower CO2 emissions and improve a ship’s Energy Efficiency Design Index.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Women in Maritime Today: Elin Saltkjel says no day working in maritime is dull

Events

Maritime Environmental Protection Webinar Week

Cyber & Vessel Security Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.