Business Sectors

Contents

Register to read more articles.

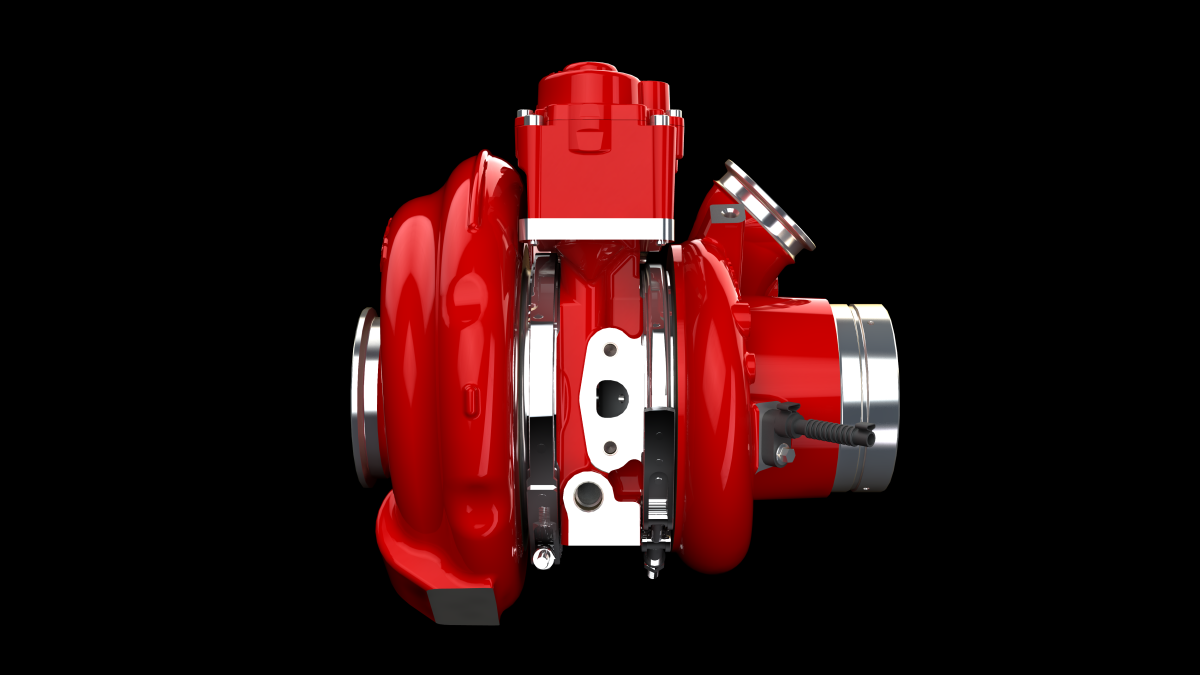

Cummins Turbochargers: engineering solutions for future fuels

Cummins, known for its durable marine engines and advanced turbocharging solutions, is leading the way in developing technology for a sustainable future

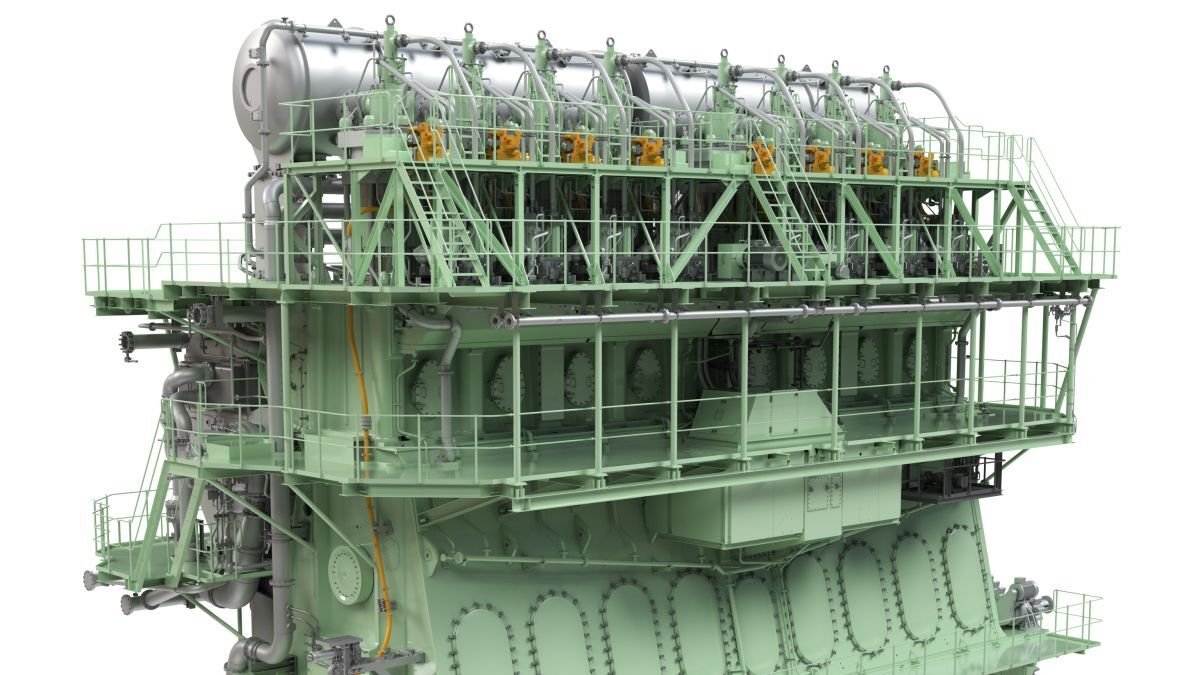

As the global maritime industry strives to reduce greenhouse gas emissions, Cummins is developing turbocharger and engine systems capable of handling alternative fuels such as methanol, hydrogen, ammonia, and biofuels. These fuels, each with unique benefits and challenges, are expected to become mainstream by 2030, driven by international regulations like IMO’s decarbonisation targets.

This article explores how Cummins is preparing its turbochargers and engines to meet the specific demands of future fuels, with insights from John Clark, executive director of research and engineering at Cummins. Mr Clark provides an in-depth look into the technological advancements that position Cummins as a leader in sustainable marine propulsion.

Integrating methanol

Methanol is one of the most promising alternative fuels in marine propulsion due to its relatively high volumetric energy density, which is higher than hydrogen but lower than diesel. However, its gravimetric energy density is lower than both diesel and hydrogen, a crucial consideration for tank size and vessel design. Methanol can be produced from green hydrogen or biomass, allowing it to be used in a carbon-neutral production process. Cummins is adapting its engines to integrate methanol as a primary fuel source. Methanol-fuelled engines benefit from lower nitrogen oxide (NOx) emissions, aligning with IMO Tier III standards without requiring complex after-treatment systems.

“Cummins’ turbochargers are designed to ensure optimal air-to-fuel ratios, compensating for methanol’s lower calorific value, thereby maintaining power output while minimising environmental impact,” says Mr Clark.

Hydrogen

Hydrogen, with its low carbon emissions potential, presents distinct engineering challenges due to its low volumetric energy density but high energy density by mass, making it efficient by weight but challenging for tank size and storage in transport applications. Hydrogen-fuelled engines for marine use must balance these density characteristics with available storage space, a task that requires turbochargers capable of handling large air volumes to ensure complete combustion and minimise NOx emissions.

The outlet temperature for an internal combustion engine using hydrogen as fuel is typically lower than that for diesel. This difference occurs because hydrogen requires a higher air-to-fuel ratio than diesel to prevent knock, resulting in lower temperatures at the engine outlet. Cummins’ turbocharger designs are thus engineered to maintain robustness even at the standard temperatures associated with hydrogen combustion, a critical consideration as hydrogen emerges as a long-term solution for sustainable energy.

Ammonia

Ammonia is promising for shipping due to its carbon-free combustion, though it brings challenges such as slow ignition, toxicity, and high NOx emissions. Cummins has optimised its turbocharger technology to meet these demands, including components like twin-entry turbines and variable geometry systems that support ammonia combustion. “The slow ignition speed and high ignition temperature of ammonia necessitate turbochargers capable of delivering high boost pressures,” Mr Clark states. To address ammonia’s elevated NOx emissions, Cummins uses selective catalytic reduction (SCR) technology, ensuring compliance with IMO’s environmental standards. Cummins is also researching ammonia’s impact on the engine, given its corrosive nature, to ensure it can be safely used as a marine fuel in the coming decades.

“Biofuels are valuable as a drop-in solution”

For biofuels and renewable diesel, Cummins has developed turbochargers that optimise combustion efficiency despite the differing properties of these fuels, such as higher viscosity and lower energy content than conventional diesel. “Biofuels are valuable as a drop-in solution,” says Mr Clark, “allowing existing engines to transition without extensive modifications.” This compatibility with existing engines is key to biofuel adoption, providing a straightforward path to reduced CO₂ emissions without overhauling current systems. Cummins’ turbochargers support this transition, maintaining diesel-like performance while enabling biofuel-powered engines to operate with reduced emissions.

In addition to these technical advancements, Cummins is leveraging digital tools to optimise turbocharger performance for alternative fuels. By embedding smart sensors and real-time monitoring systems, Cummins’ turbochargers can continuously adjust to deliver the right amount of air to meet the right air-to-fuel ratio requirements according to the specific fuel in use. “The digital integration supports predictive maintenance,” Mr Clark explains, “helping ship operators avoid downtime while maximising fuel efficiency.” Predictive maintenance is crucial in the marine industry, where unscheduled downtime incurs significant costs. This technology is particularly useful for dual-fuel engines that switch between diesel and alternative fuels like methanol or hydrogen, ensuring smooth operation across varying load conditions and fuel characteristics.

Electrifying turbochargers

Cummins is also exploring electrified turbochargers, which could play a transformative role in future propulsion systems. Combining an electric motor with the turbocharger, electrified turbochargers can provide rapid response and energy recovery. Mr Clark notes: “Although this technology is still in development, it offers promising solutions for applications where transient response and fuel efficiency are critical.” By pairing electrified turbochargers with hydrogen engines, Cummins can meet the air demands required for hydrogen combustion while preparing for a future where hydrogen is a primary marine fuel. Electrified turbochargers could significantly enhance performance by reducing lag time in turbocharging and improving overall fuel economy.

“Digital integration supports predictive maintenance”

Cummins’ turbocharger development prioritises flexibility and modularity, allowing for the seamless integration of alternative fuels. “We’ve designed our turbochargers to adapt to different operational requirements, including engines that might switch between biofuels and diesel blends,” Mr Clark says. This adaptability is essential for shipowners transitioning gradually from fossil fuels to cleaner alternatives, minimising capital expenditure and ensuring long-term viability. Modular designs enable Cummins to respond quickly to market demands and regulatory changes, allowing vessels to transition to alternative fuels without a complete engine overhaul.

However, the lack of infrastructure for ammonia and hydrogen refuelling remains a significant industry challenge. While Cummins is addressing fuel flexibility through dual-fuel capabilities, it is also actively collaborating with industry stakeholders to accelerate the development of refuelling infrastructure. “We’re committed to helping our customers adopt these fuels seamlessly once the infrastructure is ready,” Mr Clark affirms. By working with industry partners, Cummins aims to create a more accessible environment for ammonia and hydrogen, supporting sustainable choices with confidence.

“Cummins can meet the air demands required for hydrogen combustion”

Cummins’ commitment to sustainability extends beyond current technologies. The company is researching advanced materials to enhance durability when exposed to alternative fuels. For instance, hydrogen and ammonia impact metal components differently, requiring rigorous material testing. Cummins has received support from the Advanced Propulsion Centre for its work in this area, which includes testing materials under high temperatures and various fuel environments. “We’re dedicated to understanding the long-term impact of hydrogen on materials,” Mr Clark shares, “which is crucial for maintaining durability and safety across applications.” This research not only supports Cummins’ current efforts but also future proofs its technology for the evolving demands of the industry.

Cummins’ ongoing research and development align with the maritime industry’s IMO 2050 targets, which call for a 50% reduction in greenhouse gas emissions by mid-century. Cummins is developing a portfolio of solutions that extend beyond traditional engines, including hybrid configurations that combine fuel cells with conventional engines, which could further reduce emissions and enhance efficiency. By integrating fuel cells, Cummins aims to create hybrid systems that balance power output with environmental impact, paving the way for cleaner marine operations.

Moreover, Cummins’ expertise in turbocharging allows it to support a range of alternative fuels. As the marine industry moves towards cleaner, more sustainable propulsion methods, Cummins’ turbocharger innovations in fuel flexibility, real-time optimisation, and digital integration are essential. Cummins is addressing both the immediate technical requirements of alternative fuels and positioning its technology to adapt as fuel types and industry standards evolve, making it an invaluable partner for shipowners navigating the complexities of a low-carbon future.

Mr Clark summarises Cummins’ vision with clarity: “Our mission is to push the boundaries of performance and efficiency in turbocharging, while always keeping the unique needs of commercial applications in mind.” This forward-thinking approach is central to Cummins’ strategy, embracing the challenges posed by future fuels. By refining its turbochargers and engine systems, Cummins is not only reducing emissions but also enhancing performance and fuel efficiency across a broad range of applications.

In summary, Cummins’ commitment to innovation and sustainability underscores its leadership in the transition to alternative fuels in the marine industry. With advancements in methanol, hydrogen, ammonia, and biofuel technology, Cummins is setting new standards in turbocharging and fuel adaptability. By investing in electrified turbochargers, predictive maintenance, and modular designs, Cummins is creating solutions that are both practical and sustainable. As the shipping industry faces increasing pressure to decarbonise, Cummins’ technologies provide a robust pathway to a cleaner future, to help support the sector’s sustainability goals.

This illustrates Cummins’ pivotal role in advancing engine performance and setting the groundwork for a transformative shift in the maritime industry. With the integration of alternative fuels, advanced turbocharging, and digital technology, Cummins is well-prepared to meet future demands for marine propulsion, ensuring it remains a key player in the global fight against climate change.

Related to this Story

Events

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.