Business Sectors

Events

Contents

Driving the efficiency of four-stroke engines to ‘a different level’

A Rolls-Royce executive emphasises the need to take ‘pragmatic but progressive steps’ to drive efficiency and emissions reductions, including collaborating with shipbuilders

It’s hard to beat the efficiency of the internal combustion engine (ICE), and thanks to continuous refinements by marine manufacturers, it has only gotten better with the passage of time.

“There is not a better energy converter than an internal combustion engine,” declared Rolls-Royce Solutions, Asia, commercial director, mobile business, APAC, Chew Xiang Yu. “Years ago, it was around 28%. These days it is more like 40 to 45%,” he said.

Mr Chew was on hand at the Offshore Support Journal Conference, Asia in September to discuss Rolls-Royce’s efforts in supporting offshore support vessel (OSV) owners, operators, shipbuilders and other maritime stakeholders in reducing CO2 and greenhouse gas (GHG) emissions to meet international, regional and national regulatory requirements.

Rolls-Royce manufactures four-stroke, high-speed MTU engines that are widely used in OSVs, offshore windfarm vessels, ferries, tugs, patrol craft and other types of workboats.

“How can we take very pragmatic but progressive steps towards sustainability in the OSV market?” asked Mr Chew. “With IMO coming together in October, you will see more emphasis on emissions and more emphasis on fuel consumption,” he said.

He said the enginemaker’s four main pillars to support client’s net zero goals are: sustainable fuels; hybrid technologies; methanol and hydrogen engine development; and digital initiatives.

About 98% of the global merchant fleet is powered by ICEs. But he pointed to the increasing use of ICEs in combination with batteries in hybrid propulsion applications in OSVs and in other sectors to improve efficiency, reduce fuel consumption, lower maintenance costs and cut emissions.

There are now some 1,072 vessels in operation and another 468 vessels under construction with battery storage. Of those, 82% are employed in either hybrid or plug-in hybrid applications. The remaining 18% are pure electric-powered vessels, according to DNV Alternative Fuels Insight.

When it comes to reducing CO2 and greenhouse gas emissions to meet regulatory requirements, another key feature of an ICE is its fuel flexibility. “ICE is not the problem. It is a matter of what you are burning,” Mr Chew said.

“The engine itself is a component in the total sum of efficiency”

Rolls-Royce is developing methanol engines. The big question, said Mr Chew, was whether the marine industry was ready for methanol. MTU hydrogen engines are also in development, but he sees those being deployed first in the land-based power-generation market.

When it comes to using data and digital solutions, Rolls-Royce is striking a balance between preventative maintenance and corrective maintenance. “One gives you a better certainty on uptime and the other gives you a better optimised cost of ownership,” he noted.

He also pointed to advances in turbocharging and fuel injection systems that allow engine makers to generate more power density and fuel efficiency in the same footprint.

SCR technology

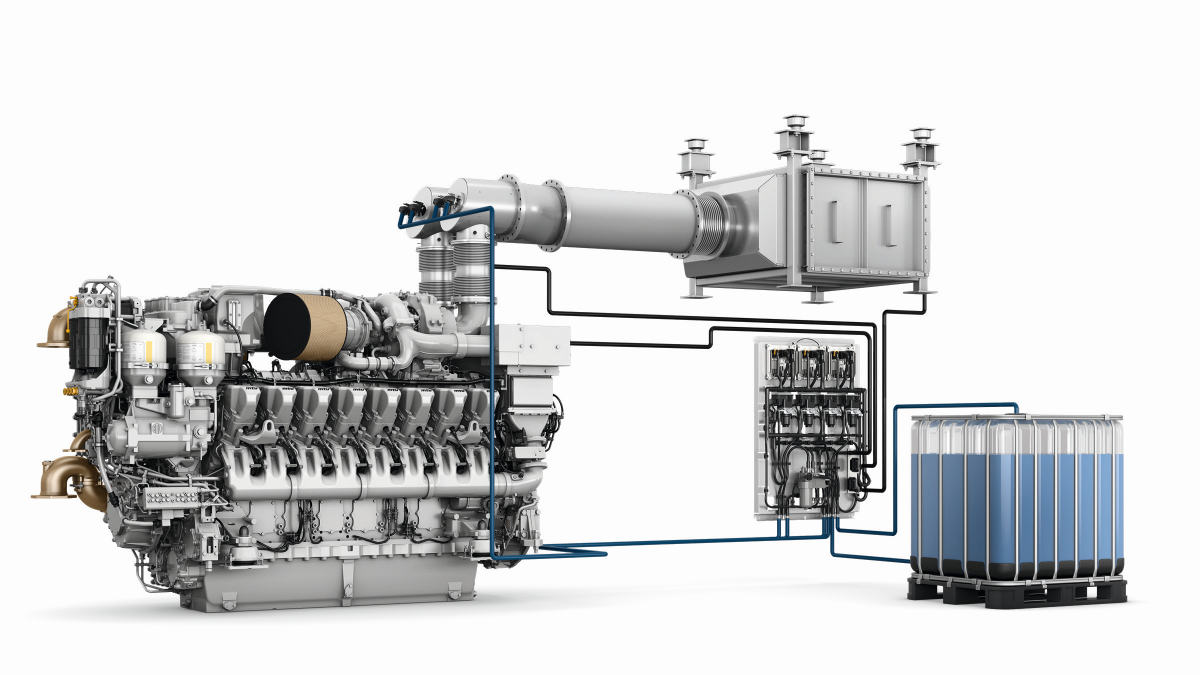

Reducing or maintaining the engine footprint is critical in vessel design, as enginerooms become more congested with the use of exhaust aftertreatment systems to meet IMO Tier III requirements. Engineers at Rolls-Royce have tackled this issue and developed a more compact selective catalytic reduction (SCR) system. Rolls-Royce is deploying these compact exhaust aftertreatment systems in combination with its 16-cylinder MTU Series 4000 engine for yachts, tugs, and ferries. The enginemaker says the new generation of MTU Flex SCR systems require 42% less space and weigh almost 40% less than previous systems.

A new ceramic material is used in the system which is anticipated to yield increased service life by as much as 18,000 operating hours (depending on the load profile) and a 15% reduction in life-cycle costs. Rolls-Royce expects to gradually rollout the new generation of MTU Flex SCR system on other MTU engines as well.

Ships that have MTU engines and SCR systems in the power range between 2,176 and 2,560 kW can be operated in Emission Control Areas (ECAs) and comply with IMO Tier III. This is particularly noteworthy with the proliferation of global ECAs and regional emissions regimes.

According to Rolls-Royce, the MTU Flex SCR system reduces NOx emissions by 75% compared to IMO II limits.

And when it comes to vessel design, these new SCRs are particularly advantageous in tight enginerooms, where space is at a premium. System components can be installed horizontally, vertically, upright, or suspended in the engineroom, depending on requirements. The engine maker has reduced the weight of the new exhaust aftertreatment system by almost 40% compared to the previous MTU Cube Box.

Collaboration with builders

Vessel design innovation is also critical to efficiency, said Mr Chew, who emphasised the role of collaboration with shipbuilders, noting Rolls-Royce’s partnership with Singapore shipbuilder Strategic Marine. “The engine itself is a component in the total sum of efficiency,” he said, adding, “we need to work with like-minded individuals.”

Strategic Marine and Rolls-Royce collaborated on a series of three 35-m surface effect ship (SES) crew transfer vessels, built for operation in the offshore oil and gas market in Angola under a charter to TotalEnergies. Based on an AIRCAT Crewliner design and equipped with four 16-cylinder MTU Series 2000M72 engines, these vessels use a combination of air-cushion technology and catamaran-style hull to reach speeds of more than 53 knots.

The vessels’ optimised power-to-weight ratio and use of powerful fans to generate an air cushion between their hulls minimises hull drag and resistance. Combined with the MTU Series 2000M72 engines, the vessels can travel at much higher speeds than conventional monohulls and catamarans, with consumption remaining at the same per hour of operations. Because of their high speeds, the SES crew transfer vessels can reduce transit times, while their low hull resistance saves fuel and reduces emissions.

By collaborating on the AIRCAT Crewliners, Mr Chew said Rolls-Royce and Strategic Marine “worked together to really bring efficiency to a different level”.

Related to this Story

Events

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.