Business Sectors

Events

Offshore Support Journal Conference, Middle East 2025

Contents

Register to read more articles.

From peanut oil to ammonia: the future of the diesel engine

Everllence senior vice president, head of two stroke business, Bjarne Foldager, discusses the five-year journey to the engine designer’s first ammonia dual-fuel two-stroke engine

With roots stretching back some 260 years, Everllence is no stranger to making history. The enginemaker’s DNA is built on technological milestones. Among those are the development and manufacture of the world’s first diesel engine, together with Dr Rudolf Diesel between 1893 and 1897, and the first seagoing ship, Selandia, with diesel propulsion in 1912. You can reach out and touch this history at Diesel House, a museum in Copenhagen that celebrates innovation and the birth of the diesel engine. It is built around B&W2000, a massive 22,500-hp, eight-cylinder, double-acting two-stroke engine that was built in 1932 to produce electricity for the city.

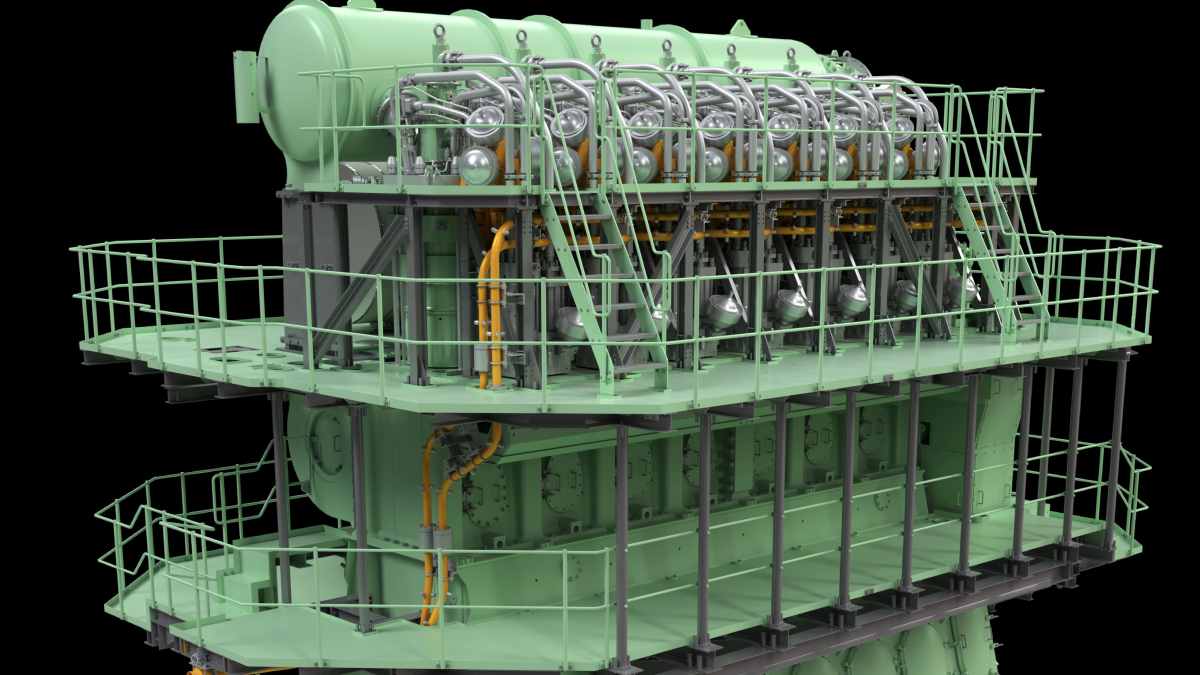

When Dr Diesel demonstrated his first diesel engine at the 1900 Paris World’s Fair, it operated on peanut oil. With Diesel House providing an appropriate backdrop, Marine Propulsion sat down with Everllence senior vice president, head of two stroke business, Bjarne Foldager, to discuss the future of the diesel engine and the company’s latest milestone: the introduction of its first two-stroke, slow-speed, ammonia dual-fuel engine. Mr Foldager explained why it was necessary for the company to take the technological leap to develop the new B&W ME-LGIA (liquid gas injection ammonia) dual-fuel engine, how the process differed from past marine engine rollouts and what the next steps are for its commercialisation.

Over the last decade, Everllence has developed and commercially launched two-stroke, slow-speed dual-fuel engines capable of burning LNG, LPG, ethane, and methanol, offering shipowners the flexibility of selecting the right engine platform and low-carbon intensity fuel for their ship type and route to minimise CO2 and greenhouse gas (GHG) emissions. The engine designer’s R&D efforts have been shaped by owner demands to meet IMO’s GHG emissions reduction ambitions and regional environmental regulations, such as FuelEU Maritime and EU ETS. In all, more than 1,900 alternative fuel-capable engines have been sold by the engine designer since the first ME-GI methane-burning prime mover was delivered more than a decade ago. That accumulated experience has underpinned the development of the ammonia dual-fuel engine.

“For the ammonia engine, we need to have a completely new level of maturity”

But Mr Foldager said in the case of ammonia, Everllence probably spent the most time on developing the B&W ME-LGIA, and it was “the most mature before we sent it to the market.” Mr Foldager said it was decided early on by Everllence – previously known as MAN Energy Solutions – that safety would be paramount in the engine’s development to mitigate any risk in the use of ammonia as a fuel, which is highly toxic.

“We have maintained that position,” he stated. “For the ammonia engine, we need to have a completely new level of maturity before we launch it to the market.” Mr Foldager said the company was under “an enormous amount of pressure” because other engine designers have launched their engines “at an earlier maturity stage, putting pressure on us.”

Despite the commercial pressures, the company stayed the course. It conducted full-scale engine tests at the Research Centre in Copenhagen in 2024 and full-scale testing on a commercial ammonia engine at Mitsui Tamano Works in Japan in 2025. After 150,000 hours of collective work, some 800 tests in Copenhagen and Japan and five years of R&D, Everllence unveiled the engine during a two-day event in mid-November that drew some 350 shipowners, operators, shipbuilders, ports, fuel providers and other maritime stakeholders from around the world.

In the quest to reduce shipping’s CO2 and GHG emissions, Mr Foldager said: “Ammonia is a wonderful fuel because there is no carbon,” adding, “because it is slow burning, it’s perfect for the two-stroke engine.” He said: “There are clear indications that the efficiency is even higher than [for] traditional diesel oil.”

When assessing it through the prism of decarbonisation, you can see why Mr Foldager describes ammonia as a “wonderful fuel.” Ammonia, NH3, is an excellent hydrogen carrier, it is carbon- and sulphur-free and when produced using renewable energy (so-called ‘green ammonia’) becomes a carbon-neutral fuel from a well-to-wake perspective. Additionally, it eliminates concerns around black carbon, methane slip and CO2 emissions.

“Ammonia is a wonderful fuel because there is no carbon”

Initially ME-LGIA engines, like other alternative fuel-capable Everllence B&W two-strokes, will have 5% specific pilot oil consumption.

But Mr Foldager was candid in assessing the risks of ammonia as a marine fuel. “It is toxic,” he said, noting concerns with leakage or ammonia slip in the engine. “It is toxic in handling, not only in the engine, but also in the systems: bunkering, the auxiliary system, the fuel gas supply system, the ventilation system, and emissions. We want to be sure that whatever ammonia comes out of the stack is of extremely low values.”

Mr Foldager emphasised that Everllence has had significant success in mitigating ammonia slip – unburned fuel escaping out of the stack – and nitrous oxide (N2O), which is a by-product of combusting ammonia. N2O, also known as laughing gas, is a powerful GHG gas with a GWP of 273, according to the US EPA.

Data shared during the Everllence event showed ammonia slip at less than 6 ppm across the entire load range. NOx emissions were well within compliance with both Tier II and Tier III regulations as ammonia combustion generates less than 50% of that of diesel combustion. Additionally, N2O, even at 100% load, was well below 2 ppm.

“Efficiency is even higher than for traditional diesel oil”

“The figures for both laughing gas and ammonia slip are in the single digit ppms. We are very proud of what we have achieved,” he said.

To minimise ammonia slip, Mr Foldager said Everllence spent an enormous amount of time on the actual injection process, researching spray patterns, pressure, and the design of the injector. He said the injection that Everllence is using is so-called ‘low sac volume’. Using a small amount of ammonia in the fuel injector nozzle affects the spray characteristics, allowing for the optimisation of atomising of the fuel and reducing unburned fuel.

“We are where we want to be when it comes to ammonia slip,” he said.

More work ahead

But Mr Foldager said that more work remains. “Where we need more work is in the actual system integration. The engine alone is not enough. You need all the other systems on the ship, the fuel gas supply system, the purging system, the ventilation system, etc. How those systems interact is an area where we really need to work very closely with the shipyards, ship designers and enginebuilders to make sure that we optimise the whole system,” he said.

Additionally, all ME-LGIA units will be equipped with a selective catalytic reduction (SCR) system. “If there is a small amount of unburned ammonia from the combustion, we use that in the SCR to further reduce the levels (of NOx slip). The SCR is now interactive with the engine. It is not a separate system now. The engine interacts directly with the control system and the SCR,” he observed. Mr Foldager explained that the interaction with the engine, control system and SCR comes into play when there is “not sufficient ammonia available in the slip.” At that point, he explained, urea could be added when operating in a Tier III area.”

Pilot projects and next steps

Next year will be a big one for Everllence and its ammonia engine, marked by type approval testing and initial service experience. According to Everllence, the first ME-LGIA engine will be delivered in Q1 2026, with bedding-in set for Q4, 2025. Mr Foldager said the company has about 20 pilot projects, many of which have not been made public.

Among those that have been made public are deliveries of Everllence B&W 6G60 ME-LGIA engines for two very-large ammonia carriers for Eastern Pacific Shipping, with factory approval testing (FAT) in Q1 2026 and delivery in Q3 2026.

A further four Everllence 7S60 ME-LGIA engines are destined for four Höegh Autoliner 10,800-CEU pure car and truck carriers. FAT is set for Q3 2026 and delivery in Q2 2027.

And another 7S60 will sit in a Newcastle bulk carrier in Japan, where the engine is currently on the Mitsui E&S testbed.

Mr Foldager said these engines were critical for gaining “the first real life experience in a ship” and “how the shipowner and crew interact with the engine.”

The digitally connected engine

Another important element will be collecting data from each of the engines in service.

“We have developed digitally connected engines. It’s real-life, high-resolution data. It means we receive 500 data points from the engine every minute, 24 hours/seven days a week, 365 days a year. The electronic engine itself produces about 2,000 signals continuously, and 500 of those signals are sufficient for us to know exactly what is happening in the engine,” he said. “It’s data that is generated in the engine from the control system with the sensors. So that means the data quality is impeccable,” said Mr Foldager. “We already have 1,000 engines that are connected this way,” Mr Foldager observed.

The data will enable Everllence to understand the overall health of the engine, troubleshoot any problems before they arise and ensure safety. “We insist that our ammonia engines are connected for two reasons,” explained Mr Foldager.

“The engine alone is not enough”

“First, we need to support the shipowner in the safe and reliable operation of the ammonia engines. We monitor this data 24/7 at our manned remote operation centre to support the owner and the crew.”

Remotely monitoring the data from the engine allows Everllence to make recommendations on optimising engine performance and increasing efficiency.

“In our standard performance report, we have a total of 13 different parameters that we monitor and score to see if the engine can be further optimised,” said Mr Foldager. He said, for example, data can show if the turbocharger is starting to foul. “As a result, we can recommend to the owner that it is probably a good idea to clean the turbocharger now.”

The owner can use the performance report to decide which actions they want to take.

“Second, it allows us to troubleshoot. If there is an issue with the engine, then we have all the data that we need. It enables our engineers to troubleshoot much faster than the traditional way, where we would send an email to the ship’s chief engineer asking them to extract the data and send it back by email. We must wait to receive the data the next day, before looking at it. With the connected engine, we have it instantly,” said Mr Foldager.

One key message that Mr Foldager wanted to share in wrapping up the interview was offered on a slide at the Everllence event. It said simply: ‘We are ready.’

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

Maritime Decarbonization Conference, Americas 2026

Offshore Wind Journal Conference 2026

© 2024 Riviera Maritime Media Ltd.