Business Sectors

Events

Contents

Maximising efficiency with compact and lightweight single-stage turbochargers

Hedemora Turbo & Diesel’s turbochargers are designed to ensure flexibility onboard and enable simple maintenance

No turbocharger works harder than a turbocharger on a supertrawler. These giant deep-sea fishing factories conduct all their processing on board. So, when Hedemora Turbo & Diesel was asked to replace its older H6-1 blowers on a fleet of Russian-owned vessels, the solution came in the form of the Sweden-based group’s latest HS5800 models.

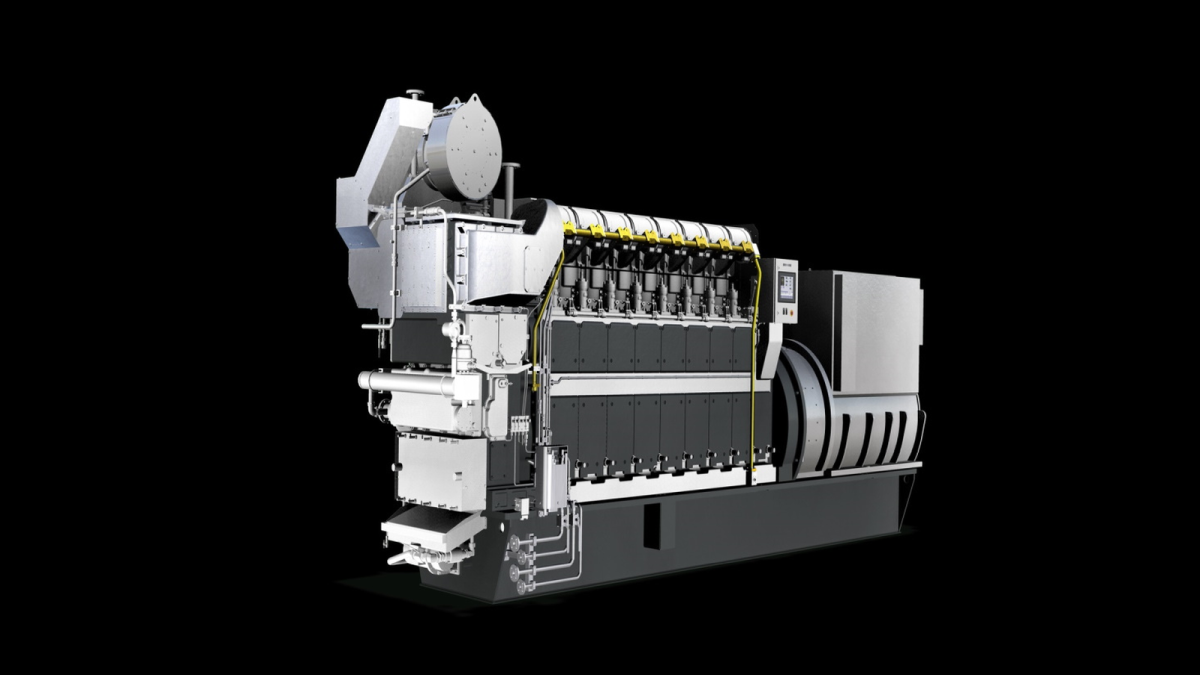

These compact and lightweight single-stage turbochargers, with a total peak efficiency pushing 72%, produced immediate results when installed on the supertrawlers’ German-made, six-cylinder, four-stroke SKL engines.

Designed primarily for diesel, gas and HFO engines between 1,200 and 4,200 kW, the turbochargers in the HS range are among the most efficient single-stage units. They do not require water cooling and are easily repaired and maintained on-site, without the need for special tools.

HS designs use high-strength aluminium alloy impellers, coupled with Inconel turbine wheels. The design of the rotor allows for simplified servicing and keeps costs and downtime to a minimum. Where necessary, the rotating components can be individually replaced in the field without the need to rebalance the complete rotor assembly.

“The rotating components can be individually replaced in the field”

The main bearings are positioned inboard of the compressor and turbine wheels, allowing a compact construction. Both compressor and turbine casings can be phased to allow the products to be adapted to installation on all engine applications.

Efficiency is everything on big units like the SKL. When the turbocharger is worn-out, the performance of the engine declines, leading to a variety of problems. Exhaust gases accumulate in the combustion chamber, cylinders and pistons overheat, and less oxygen is available for combustion. The consequences are expensive, in the form of wear and tear on the engine, as well as higher fuel consumption. The installation of the HS5800 turbochargers produced immediate gains. Using the Hedemora units, the operator noted “significant improvements in the scavenge gradient across the entire operating range” and also cited benefits in the engine’s in-cylinder dynamics.

Manufactured in Hedemora’s US factory in Columbus, Ohio, the HS5800 is a neat and versatile unit. Weighing 430 kg, it covers an engine power range of 1,500 to 3,700 kW and puts out a maximum pressure ratio of 4.5. It is also extremely durable, running without maintenance for as long as 24,000 hours.

Although Hedemora’s engineers expected efficiencies, they were surprised by how lean the SKL engines were running, with a bigger drop in fuel consumption than had shown up in factory tests. “We have found that very good results can be achieved even on lower boost pressure,” said Hedemora.

When Hedemora engineers fitted a blower to an entirely different type of engine, in this case two Alco 16-cylinder units on a Mississippi River push boat, the operator was impressed by a dramatic reduction in pollution.

Widely used on push boats and tugboats in environmentally sensitive waterways, the V16 medium-speed, four-stroke diesel Alco is a turbocharged workhorse known for its high specific output and ruggedness. Because power output typically ranges from 6,200-8,000hp, superchargers play a fundamental role in cleaning emissions.

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.