Business Sectors

Contents

Register to read more articles.

Napier Turbochargers: maximising efficiency and fuel flexibility

As IMO regulations steer shipping towards decarbonisation, Napier is developing high-efficiency turbochargers capable of handling traditional and low- and zero-carbon alternative fuels

With ambitious goals set by IMO, including reducing greenhouse gas emissions by 50% by 2050, the need for high-efficiency turbochargers capable of handling traditional and alternative fuels is more pressing than ever. Napier Turbochargers, partnered with Wabtec, has technologies that address fuel challenges through highly adaptable and efficient turbocharging systems.

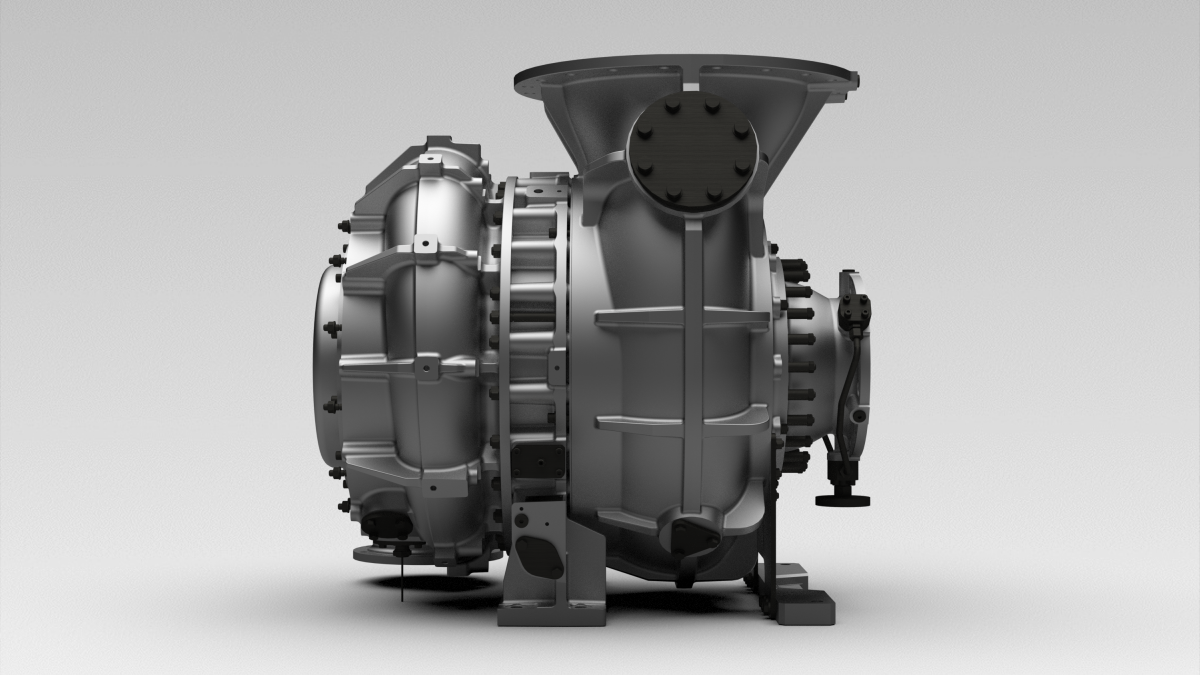

This collaboration positions Napier as a leader in turbocharging for both marine and industrial applications. Its NT1 and NT2 series are engineered to deliver high efficiency while operating under varying fuel conditions, maximising performance and minimising emissions. Napier’s commitment to producing turbochargers designed for alternative fuels, such as ammonia, hydrogen, methanol, and biofuels, highlights its role in helping engine manufacturers meet the demands of evolving marine regulations and requirements.

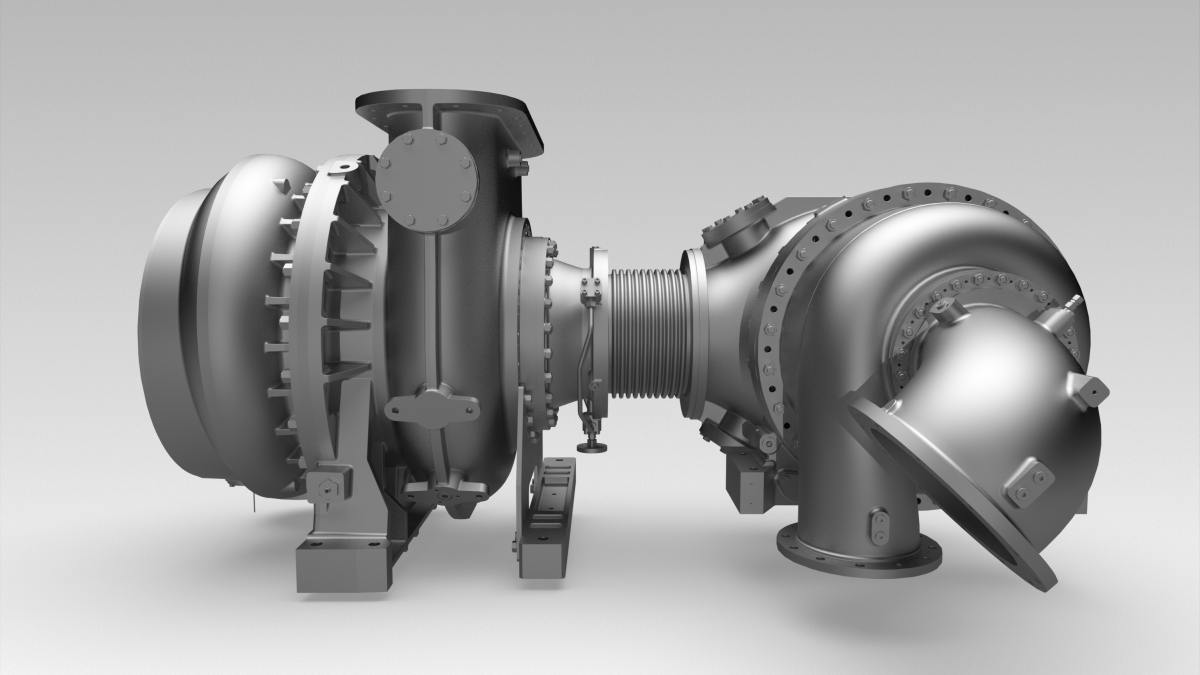

Napier’s NT1 and NT2 turbocharger series exemplify the company’s focus on efficiency and sustainability, aligning with original equipment manufacturers (OEMs) seeking robust, future-ready turbocharging solutions. The NT1, a single-stage turbocharger, is designed to optimise high-pressure conditions, achieving peak performance across diverse fuels, including heavy fuel oil, methane, and the upcoming generation of green fuels like ammonia and hydrogen.

“Methanol and biofuels often vary in quality, impacting combustion efficiency”

Describing Napier Turbochargers as an independent turbocharger supplier to the industry, Sam Tonks, Napier Turbochargers business development manager, said it works closely with various enginebuilders to help them achieve their environmental and efficiency goals. Each turbocharger is matched to a specific application, fuel type, and legislative requirements.

“Environmental regulations and subsequent alternative fuels pose a challenge to enginebuilders, to which Napier Turbocharger can provide turbocharging solutions to current and future developments, whether that be increased charge air pressure or flow rates for the engine,” he says. “Our broad portfolio of turbochargers, from 50 kW to 25 MW, allows us to be a part of enginebuilders’ commitment to sustainability. The Napier Turbocharger product development is driven by the potential new demand on charge air systems,” he says.

With the NT2 series, Napier has developed a two-stage turbocharger tailored to the high-power density requirements of next-generation engines. This dual-stage setup ensures fuel efficiency, even with multi-fuel operations combining diesel with alternative fuels like ammonia or methane. Designed to support engines that run on a mixture of traditional and alternative fuels, the NT2 series’ flexibility is essential as the industry moves towards compliance with more stringent emissions regulations.

Newly implemented EU regulations, including the FuelEU Maritime initiative and the EU Emissions Trading System, place stricter limits on CO₂ emissions for maritime vessels. These mandates effectively require shipowners to invest in more efficient engines and turbocharging systems to reduce their emissions profiles and lower operating costs associated with carbon compliance. Napier’s NT1 and NT2 series meet this demand by offering high efficiency and adaptability to multiple fuel types. By enabling ships to meet these regulations with optimal combustion and reduced fuel consumption, Napier’s turbochargers help ship operators avoid penalties, remain competitive, and contribute to broader environmental goals.

Efficiency and durability

By engineering turbochargers capable of handling future fuels, Napier leverages advanced technologies such as computational fluid dynamics and finite element analysis to refine the NT1 and NT2 turbochargers for maximum efficiency and durability. These methods enable Napier to optimise airflow and enhance resilience under high thermal stress, a critical feature in turbochargers that will operate with next-generation fuels. This precise engineering helps achieve higher fuel efficiency, reducing energy loss and ensuring optimal combustion, even in variable load situations.

“The key components in the NT series are modular”

As shipping embraces alternative fuels like ammonia and hydrogen, Napier’s turbochargers address the unique combustion characteristics of these energy sources. For instance, hydrogen combustion is characterised by high flame speeds and combustion temperatures, creating stress challenges for turbochargers. Napier’s solution is to incorporate advanced cooling technologies and thermal-resistant materials, ensuring that the NT1 and NT2 turbochargers maintain durability and efficiency even under these high temperatures.

Ammonia burns with a slower flame speed and requires a higher ignition temperature, posing its own technical challenges. Napier’s approach to ammonia-fuelled engines involves optimising air compression and boost control, enabling stable combustion and minimising the risk of releasing unburned ammonia. This focus on safe and efficient combustion ensures that Napier’s turbochargers are ready to support the fuel-flexible engines essential to the maritime industry’s decarbonisation goals.

Napier’s aftermarket services extend its commitment to efficiency and sustainability, offering retrofitting options that allow operators to transition to alternative fuels without extensive engine modifications. This retrofit programme provides upgraded cartridges and components for existing turbochargers, allowing operators to convert their engines to handle various fuel types while minimising downtime and costs. By enabling this gradual shift to low-emissions and zero-carbon fuels, Napier’s retrofits align with both environmental mandates and the financial considerations of fleet operators.

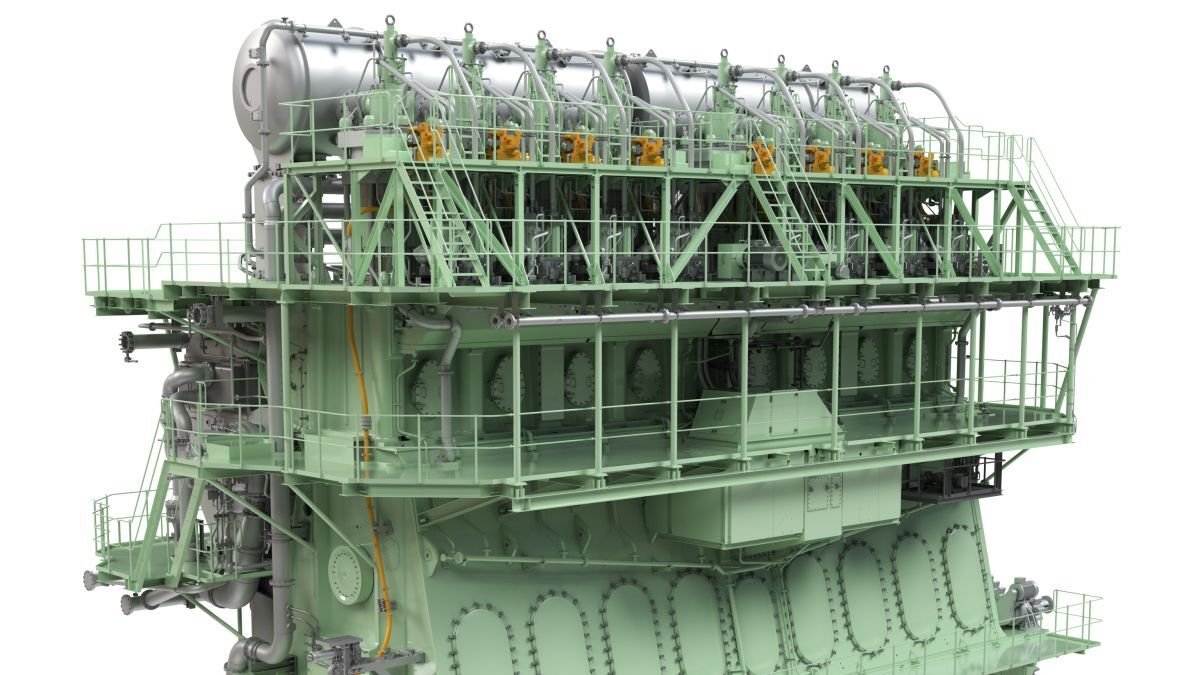

Strategic partnerships and collaboration with OEMs, including Wärtsilä and Rolls-Royce, underpin Napier’s position as a leader in turbocharger development. Collaborations like these allow Napier to refine its turbocharging solutions for compatibility with low-emissions engines, creating a propulsion ecosystem that can support the next wave of marine fuel innovation. For instance, the partnership with Wärtsilä has led to the development of the Wärtsilä 46TS-DF engine, incorporating Napier’s two-stage turbocharging technology. Designed to operate on various fuels, including LNG, ammonia, and methanol, this engine demonstrates Napier’s ability to deliver optimal performance across load conditions, meeting the versatility required by today’s modern vessels.

Napier’s collaboration with Rolls-Royce has broadened its applications in both naval and commercial sectors. These partnerships focus on developing propulsion systems that remain fuel-flexible while complying with strict emissions standards. Napier’s NT1 and NT2 turbochargers, with modular upgrade capabilities, are particularly valuable in such applications, supporting phased transitions to alternative fuels that minimise operational disruption.

The NT series of turbochargers are specifically designed to address the variable qualities of alternative fuels, each of which presents distinct operational challenges. Methanol and biofuels, for example, often vary in quality, impacting combustion efficiency. Napier’s design allows its turbochargers to adjust performance to maintain efficiency and emissions control, even when fuel quality fluctuates.

Key components in the NT series, such as the compressor and turbine wheels, are modular and can be upgraded to suit specific fuel requirements. This flexibility reduces the cost and complexity of transitioning to alternative fuels, enabling operators to incrementally upgrade their systems as supporting infrastructure expands. By adopting this modular approach, Napier facilitates a smoother, more economical shift to alternative fuels.

Related to this Story

Events

Maritime Decarbonisation, Europe: Conference, Awards & Exhibition 2025

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.