Business Sectors

Events

Contents

Analysis of engineroom data leads to intelligent operations

With knowledge of the performance of a vessel’s engine and auxiliary equipment, ship operators and onboard engineers can manage maintenance and fuel consumption, and enhance their efficiency. To this end, Kongsberg Maritime has integrated Austrian engineering consultancy AVL’s analysis package, EPOS, with its K-Chief engineroom controls to provide analysis of engine parameters, such as pressures and temperatures. Other engineering companies are also developing analysis tools with interfaces with automation systems.

AVL’s EPOS is linked to engineroom components through the K-Chief local area network (LAN) and the process network LAN. Information from sensors on the main and auxiliary engines, propulsion shaft, turbochargers, and fuel oil tanks is fed through the process LAN to K-Chief and presented on the operator stations. AVL’s EPOS mimics the information on the operator stations and provides the analysis. The information can also be sent via the ship’s satellite communications to the onshore shipmanagers’ office, says Kongsberg’s vice president for sensor sales, Stefan Bremer.

He adds, “We have integrated AVL into the Kongsberg K-Chief for the possibility of monitoring, not just a vessel’s performance, but also to compare the information with engines in a fleet of ships. There is access to data for each vessel online for onshore managers. This way they can get the full picture of performance. We can integrate third-party systems into K-Chief to provide different interfaces with operators. All the equipment on a vessel could have different systems, so we can integrate all these into one offering to the end-user.”

Condition monitoring systems product manager for AVL, Christian Strasser, says the EPOS program provides information on the condition of a ship’s engine, such as the combustion chambers. EPOS describes the engine status, including specific information about cylinders and subsystems, and provides predictions of realistic maintenance intervals.

“It provides data on fuel consumption and the mechanical stresses on engine parts”, says Mr Strasser. “It provides information on condition of the combustion chambers and differences between the cylinders. Operators can use this to determine whether there are good reasons to change equipment such as injection pumps, early or later than expected. We can also predict if fuel injection is early or late.”

EPOS can also trend liner, piston and turbocharger behaviour. The diagnosis algorithm uses ship data with logic and physical models to provide the intelligent analysis. The user interface is represented as a traffic light system, providing warnings of when maintenance is required.

K-Chief is a modular system with information coming from sensors for monitoring, for example, the torque, fuel levels, bearing wear and water-in-oil. Part of the system layout is the top dead centre (TDC) and crank angle pick-up system, mounted on the propeller shaft. The mimic picture on EPOS displays a number of calculated values such as: Pmax –maximum combustion pressure; APmax – the angle where Pmax occurs, referred to TDC; MIP – mean indicated pressure; Pexp – pressure 36 degees after TDC; Ptdc – pressure at TDC; power calculation – cylinder power in indicated kW; and cylinder pressure curve.

Two variants are on offer: K-Chief 600 is often fitted to merchant shipping, while K-Chief 700, with more functionality, is supplied to offshore vessels and passenger ships, says Kongsberg’s merchant marine sales manager, Stelios Hatzikiriakidis. The former provides a uniform interface that integrates several different onboard systems through multifunctional operator stations. It is a modular product that links machinery monitoring and control with power management, cargo monitoring, safety systems and bridge controls through a process network. Data from sensors throughout the ship is channelled to the K-Chief system through the LAN and I/O modules.

AVL and Kongsberg have received orders for the integrated EPOS and K-Chief. “We have sold 25 contracts and the first vessels are now being commissioned,” Mr Bremer says. The first systems are going on a Viking Line ferry and a Maersk Line container ship.

Siemens is providing measurement products to Greek system supplier C&A Controls & Automation, which is installing networks and display units on tanker retrofit projects in China. C&A uses Siemens low-voltage equipment, such as tank level sensors, temperature and pressure and flow transmitters.

C&A’s general manager, Stratos Karounias, explains: “We use Siemens for the monitoring of main engines, auxiliary systems, turbochargers, levels and pressures in order to control the different measuring points – we are the integrator. These provide data to our monitoring and controls that we are installing on tankers in China.

“A lot of shipowners are asking for monitoring systems because they want to have more control and to monitor vessel systems. They want to have low-level analysis and diagnostics. We offer real-time values and events data. We will also be using new measuring products from our sister company, Selectron, such as pressure and temperature and level sensors.”

Rolls-Royce’s marine engineroom control package is the Acon integrated automation system (IAS). It is designed to monitor ship operations and includes DP drives, alarm monitoring, cargo control and power management. There is also tank and ballast level monitoring, data logging and analysis, plus a load and stability calculator.

Within the IAS is an equipment health monitor that Rolls-Royce claims reduces downtime and maintenance costs. There is also a winch interface for anchor handling vessels that manages power to the winches during rig towing operations. For ships using LNG fuel, Acon has an LNG control module.

The IAS is run on a standardised software and hardware platform with common control interfaces and multifunctional displays. Acon has redundant system architecture with redundancy in the IO cabinets and control stations. These are all linked through a ringed network to reduce failure. There is also a remote monitoring mode when combined with a satellite link to shore.

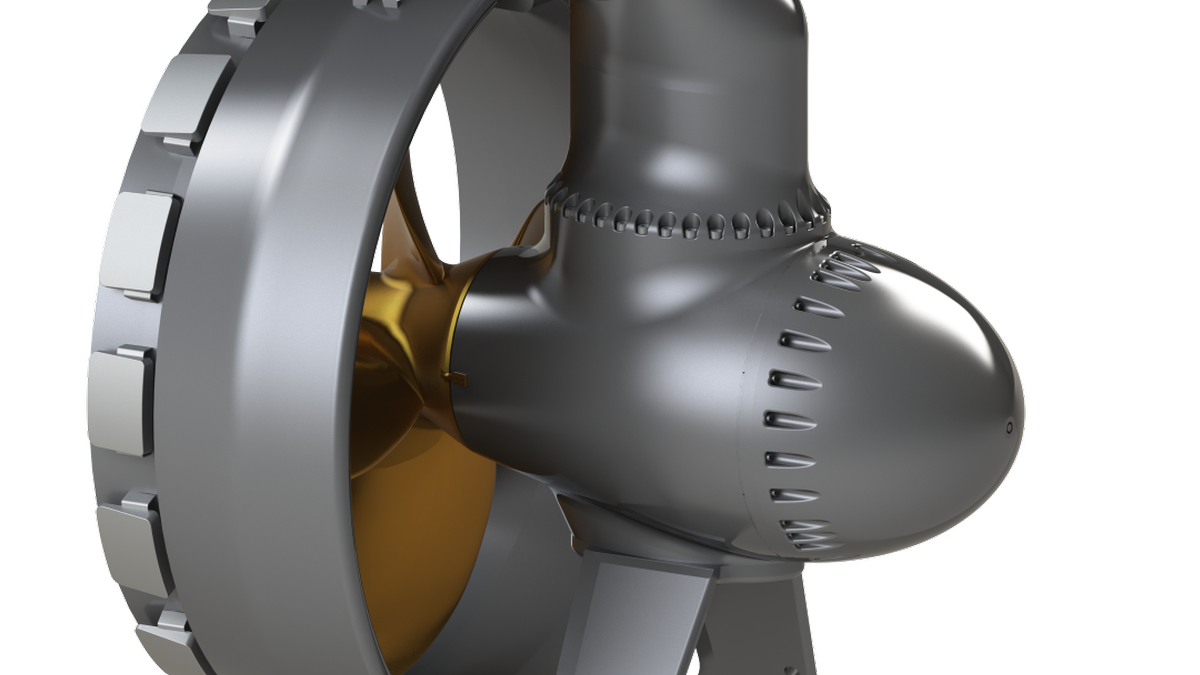

ABB has integrated the automation and control system into a complete propulsion package that includes its azipod thrusters, electric motors, low- and medium-voltage switchboards and transformers. The latest automation platform, 800xA, can be linked to monitoring systems from third-party suppliers, such as Siemens, says ABB marine sales manager, Antonis Asimakopoulos.

“We supply the total concept for the electrical propulsion, including the automation system that is linked to the drives, or invertors, which control the speeds of the azipods. The automation includes displays that include alarms and indicators of the whole system’s performance.”

Emerson Process Management can supply either a complete automation system, or package up components in a subsystem, which can be integrated with the rest of the ship’s automation. This comes under Emerson’s Marine Tank Management (MTM) automation solution, says the company’s sales manager, Jens-Christian Strate.

He says, “We can feed data to the overall automation system, from sensors such as tank level gauge radar, hydraulic activators and pump and shaft devices. With MTM Automation, we have everything together in one system, with general alarms and controls. We can control power management functions, fuel levels, make fuel efficiency calculations using the Emerson flow meters and display the fuel consumption.”

Emerson has developed a way for onboard engineering officers to remain updated with engineroom systems from their accommodation through a standalone display. It is also developing new automation and control computers that will be launched by the fourth quarter of this year.

SKF supplies monitor and analysis tools that can be integrated into automation and control systems. It has torque and vibration sensors, thrusters and gearbox monitors. SKF also supplies sensors for checking lubricant for contamination. It has introduced an online system, IMX-S, which transfers data to remote monitoring centres onshore, says SKF’s business development manager, Spiros Azzopardis.

“Our condition monitoring tools can be used as part of a condition-based maintenance (CBM) strategy”, he explains. “At an advanced level, users have the possibility of expanding the lifetime of equipment and increasing the time between overhauling equipment. We can transfer overall values from the automation system. Our remote monitoring centres will provide information to a ship’s crew and superintendents when there are early indications of problems.”

Setel Hellas has developed the SeeMBox-V ship efficiency management solution that analyses data from automation systems. The first two will be used on vessels for the first time in the third quarter of this year. It has been deployed on two Greek-owned bulk carriers, and will be installed on three non-Greek flagged vessels later this year, says Setel’s marketing director, Efthymios Chaldeakis.

“SeeMBox-V takes the signal from engineroom automation consoles and this goes to the office for remote monitoring in real-time. This is business intelligence than can be combined to go through possible scenarios, based on real data, before a failure occurs.” SeeMBox-V can interface with all automation systems, and can provide real-time analysis and comparison between similar automation equipment on different vessels, or between sister ships.

ABB gains pipeline vessels order

ABB is providing automation systems to two subsea pipeline construction vessels being built in South Korea under an US$18 million contract. The equipment will be installed on vessels under construction in Daewoo Shipbuilding and Marine Engineering (DSME)’s shipyard for French shipowner Technip and Brazilian operator Odebrecht.

As well as the automation, ABB will supply drives, motors and generators; medium-voltage switchgear, transformers and soft-starters that will provide energy-efficient propulsion; and a reliable power distribution system on board, the company claims. The vessels are due to be delivered in 2014 and will be used to install deepwater pipelines off Brazil.

ABB will also be supplying engineroom systems and controls to two new cruiseships being built for Royal Caribbean Cruises at Meyer Werft shipyard in Germany. Under a US$60 million contract, ABB will deliver power generation and distribution systems, azipod propulsion systems, motors and controls for each vessel. These are the first in Royal Caribbean’s Project Sunshine newbuilding campaign. They are scheduled for delivery in the fourth quarter of 2014 and second quarter of 2015.MP

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.