Business Sectors

Events

Contents

This ‘space ship’ counts on Rudderpropellers for precise manoeuvring

ULA will use a new roro vessel to transport Vulkan rockets to support Amazon’s Project Kuiper broadband initiative

A new roro vessel under construction in Louisiana will provide ‘special deliveries’ supporting a new Amazon venture. Those special deliveries will be high-value cargo: massive Vulkan rockets, which will be transported by water from United Launch Alliance’s Decatur, Alabama, manufacturing facility to launching pads at Cape Canaveral Space Force Base in Florida and Vandenberg Space Force Base in California. The rockets are the next generation of heavy lift launch vehicles that will be used to launch low Earth orbit satellites for Amazon’s Project Kuiper, the retailer’s satellite network that will provide the backbone for a new high-speed internet service.

United Launch Alliance (ULA), a joint venture between Boeing and Lockheed Martin, selected Bollinger Marine Fabricators (BMF) to build the steel vessel in December 2023. Last year, the Louisiana shipbuilder laid the keel for the 111-m long by 25-m wide vessel at its Amelia, Louisiana shipyard.

Called SpaceShip, the new roro vessel underpins ULA’s future launch plans. ULA vice president, Kuiper Program, Chris Ellerhorst, said his firm plans to double its launch rate capacity to support Amazon. As a result, ULA ordered a second vessel “to ensure timely deliveries of the rockets to the launch site.”

“A second vessel ensures timely deliveries of the rockets to the launch site”

Bristol Harbor Group, Bristol, Rhode, was selected by ULA to design the specialised transport vessel. This is not the first time that the Rhode Island naval architectural firm has supported the aerospace industry. Among its previous design experience is the 94.4-m NASA barge Pegasus, used to transport the Space Launch System core stage along rivers and open ocean.

Mr Ellerhorst said his firm’s first ship, RocketShip has been in service for decades. “With this second ship called SpaceShip our maritime fleet will enable enterprise transportation capacity of four Vulcan launch vehicles across two voyages to either the East or West Coast.”

Manoeuvrability

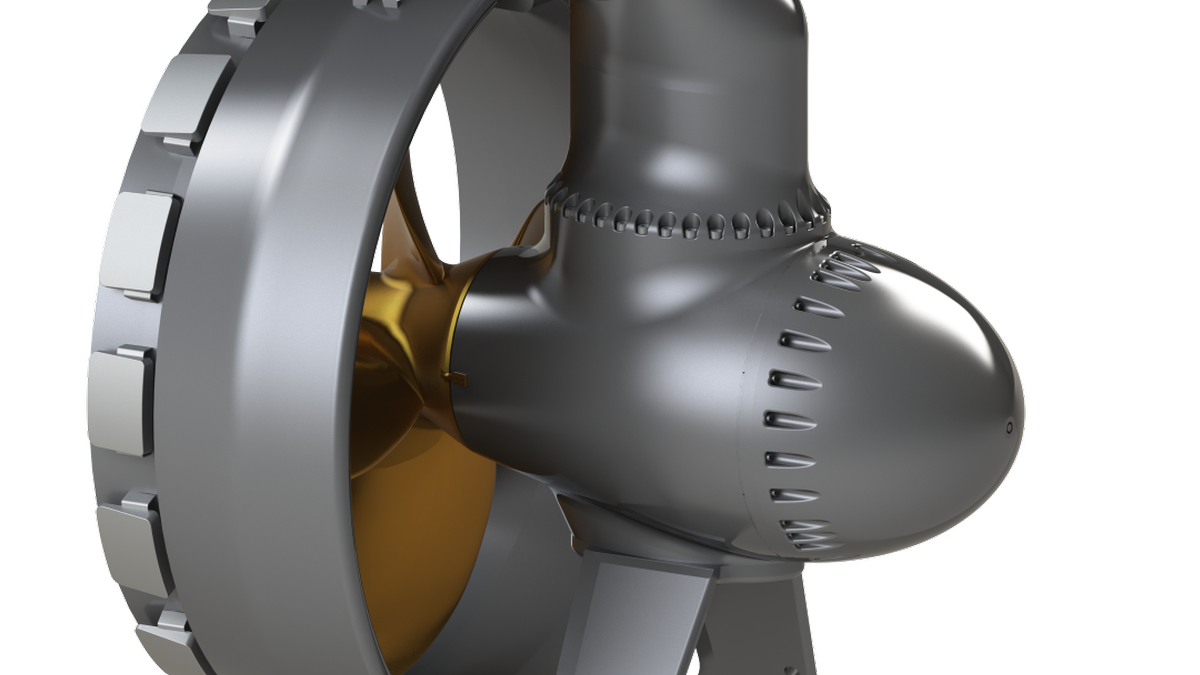

Transporting high-value cargo on rivers or in open oceans requires precise control, safety, stability and manoeuvrability. To address this, the vessel will be equipped with three Schottel SRP 460 LE Rudderpropellers, and two Schottel STT 1 Transverse Thrusters.

Since first introduced in 1999, more than 1,000 SRP 460 Rudderpropellers have been delivered, making it one of the world’s most popular azimuth thrusters. These units have undergone continuous refinement over the last 25 years.

The three SRP 460 LE-Drives for SpaceShip are what the German propulsion specialist calls “an embedded L-Drive variant”, which was developed in response to increasing demand for electric drive concepts. Each unit has an input power of 2,100 kW and a propeller diameter of 2.6 m, enabling the 111-metre-long and 25-metre-wide vessel to reach a maximum speed of 15 knots. The 360-degree steerable SRP combines high manoeuvrability with exceptional course stability during free sailing and provides powerful thrust in any direction.

Flexibility is a hallmark of the LE-Drive because it allows the owner, designer or shipbuilder a choice of electric motor for diesel-electric or purely battery-powered vessels. Additionally, with its compact design, the integrated LE-Drive allows even more vessel design freedom compared to conventional SRP Z and L variants, according to Schottel.

What is particularly noteworthy about the SRP L-Drive variant is its compact electric motor, which is embedded in the thruster’s azimuth module. This reduces the overall height of the thruster, making it easier to install in confined spaces or compartments where other machinery requires a lot of space. From an opex standpoint, the unit’s fewer mechanical parts reduce mechanical loss, making it more efficient, while lowering maintenance costs.

Transverse thrusters

Two STT 1 transverse thrusters further enhance the vessel’s manoeuvring performance. Each of these units will have an input power of 373 kW and a propeller diameter of 1.3 m. These transverse thrusters are designed to be used during docking and undocking operations in port with only a limited number of operating hours per year, or in continuous operation under high load conditions in demanding positioning tasks.

The German propulsion company’s joystick system, MasterStick, will be installed, allowing the vessel’s master to control all five propulsion units simultaneously with a single lever.

Electrical system design

Elkon, Schottel’s sister company in the Schottel Group, is engineering and supplying

SpaceShip’s tailored electric system. This will cover the delivery of Active Front End Drive technology for the main electrical propulsion system, which improves propulsion efficiency, reduces fuel consumption, and increases overall vessel performance.

According to Schottel, the scope of supply offers quieter, smoother operation while optimising energy management across ship systems.

The company will equip the vessel with main electrical switchboards, an Alarm Control and Monitoring System, which enhances operational safety by providing real-time diagnostics and proactive issue resolution, as well as a Power Management System for optimising energy distribution by integrating all generators and switchboard functions. Furthermore, Elkon is supplying motor control centers, power distribution system panels, as well as bridge and engine control center consoles.

Expectations are that SpaceShip will be delivered by BMF to ULA in early 2026.

German Aerospace Center research vessel gets next-generation CRPs

Steerprop will deliver its new next-generation contra-rotating propeller (CRP) units to Lloyd Werft Bremerhaven for installation in a new 48-m research vessel under construction for the German Aerospace Center (DLR).

The Finnish propulsion specialist said it will supply two Steerprop 14 CRP LM units, each rated at 750 kW and designed to Ice Class 1A standards.

“The new CRP design introduces pressure lubrication for smaller applications, likely making this vessel the first in the world to implement such a solution,” noted Steerprop in making the announcement. The supplier said pressure lubrication minimises mechanical losses, enabling mechanical efficiency up to 98.5% compared to the typical 95%, and enabling superior fuel economy and performance.

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.