Business Sectors

Events

Contents

First shipping sector deal for MAN 49/60 medium-speed engines

Dutch dredging and marine services provider Royal Boskalis has taken three of the engines for a newbuild dredger

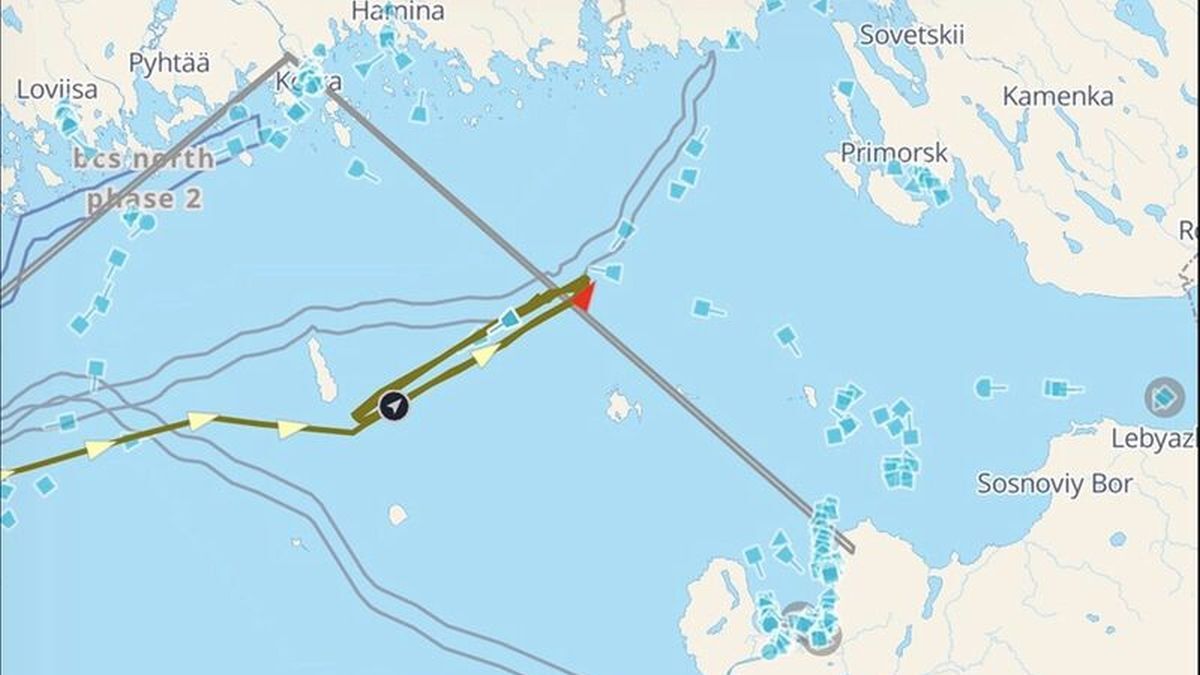

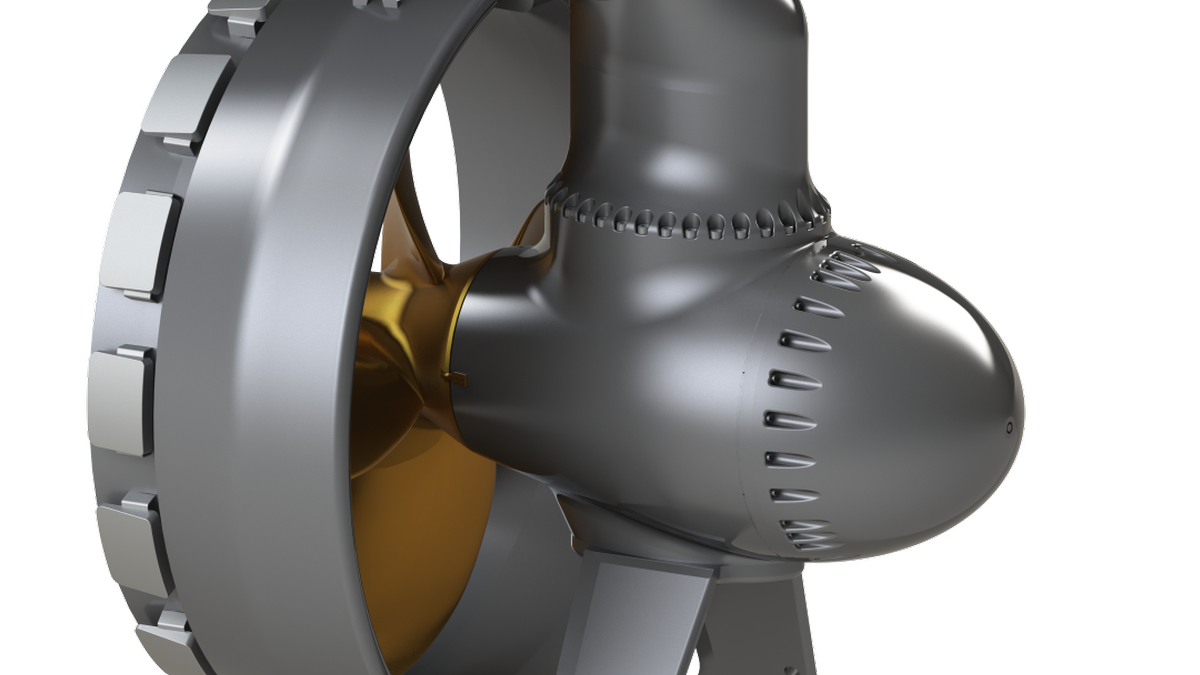

The Royal Boskalis trailing suction hopper dredger (TSHD) will be diesel-electric powered with two Azipod thrusters to allow vessel operation at shallow draught. All major drives will be electrically driven and controlled by frequency converters, according to the companies.

"The asymmetric load-sharing results in optimal load distribution over the diesel generating sets with low fuel consumption and high maneuverability," MAN Energy Solutions (MAN ES) said.

According to MAN, the Bureau Veritas-classed 49/60 main diesel engines will be able to run on either conventional fuels such as heavy fuel oil (HFO), middle distillates and marine gas oil, and sustainable fuels such as biodiesel (HVO and/or FAME). The dual-fuel engines will also be delivered as methanol-ready, capable of meeting NOx Tier III emissions limits.

"In close co-operation with Royal IHC and Boskalis, the engines have been fitted into an engineroom design similar to those used in previous Royal IHC dredger projects," MAN ES said.

The MAN 49/60 engine successfully passed its type-approval test in March 2023 and features a power-per-cylinder of 1,300 kW, reducing the number of installed cylinders necessary to meet power demands. While in this particular project six-cylinder engines are applied, the L-type of the engine can accommodate up to 10 cylinders, which makes it capable of propelling ships typically powered by V-type engines. The 49/60 is also available as 12V and 14V engine variants.

According to MAN ES, "A key determinant in choosing the 49/60 engine was its ability to fulfil the load-acceptance requirements demanded by the TSHD’s diesel-electric propulsion system in diesel mode. The next-generation MAN common-rail system 2.2, in combination with the two-stage turbocharging system used by the engine, enables it to compromise between load acceptance and efficiency. Additionally, the next-generation SaCoS 5000 engine-automation system enables the engines to fulfil cyber-security requirements and offers enhanced remote-support possibilities."

MAN ES also announced continued sales of its ME-GA engines, with Japan’s Nippon Yusen Kaisha ordering four sets of engines for a series of four newbuild LNG carriers. All eight MAN engines have MAN ES’ exhaust gas recirculation bypass systems that aim to lower emissions.

MAN Energy Solutions head of two-stroke business, Bjarne Foldager said, “We developed this engine for easy application to most contemporary LNG carrier designs and, indeed, all ME-GA orders to date have been exclusively for this segment. Demand for the engine has been continuously strong since its introduction, especially due to its accompaniment by our self-developed EGR system that comes proven by more than a decade of in-service, operational experience and optimisation.”

Join Renk’s Optimising low-speed drivetrains: exploring the advantages of front-end mounted PTO webinar, 10-11 am, 1 February

Related to this Story

Events

Offshore Support Journal Conference, Americas 2025

LNG Shipping & Terminals Conference 2025

Vessel Optimisation Webinar Week

© 2024 Riviera Maritime Media Ltd.