Business Sectors

Contents

Register to read more articles.

New engines developed for US inland waterways

Enhancements on the C32B engine make it ideal for repowering tugs, towboats and pushboats

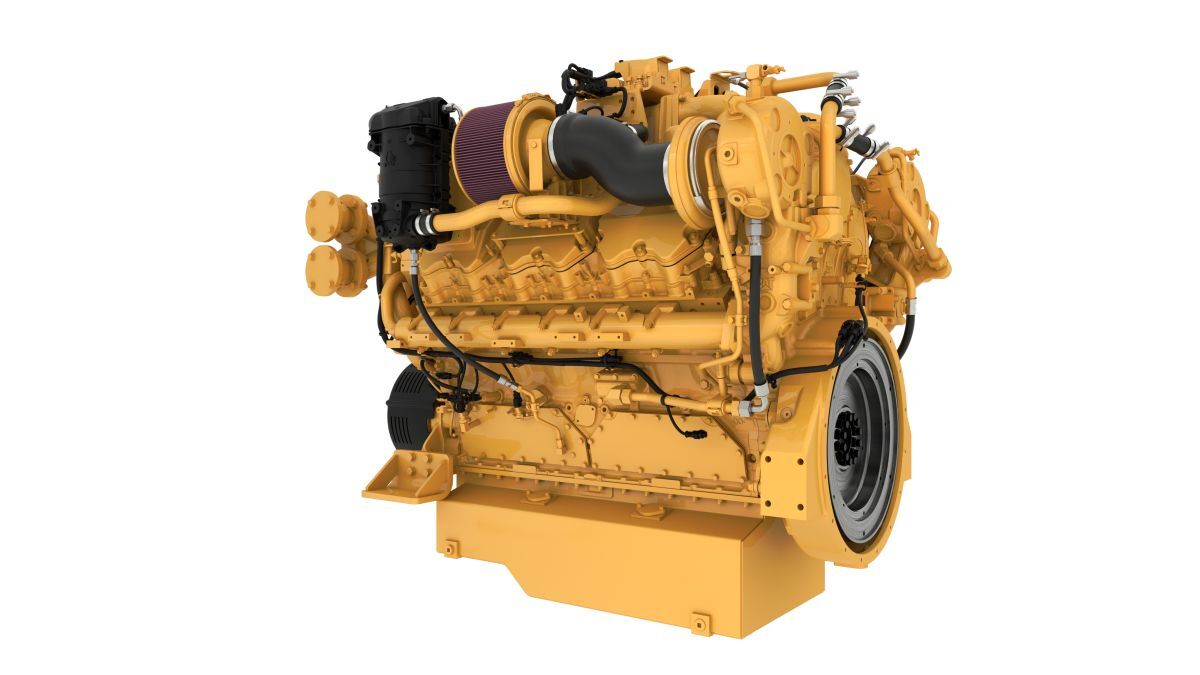

Caterpillar has upgraded its C32 engine platform for the workboat, towboat and tugboat sector and provides remote support and analysis to optimise maintenance and the time between overhauls.

The manufacturer used its experience from advancing engine technology for superyachts to enhance propulsion for towboats, pushboats and tugs in the commercial sector.

Its C32 engine series has been upgraded to become C32B and is now ideal for high-load, high-hour operations. According to Caterpillar’s account manager for the tug and inland waterways segment, Gary Sarrat Jr, C32B has been “engineered to achieve a 50% increase in time before an overhaul under certain operating conditions, significantly reducing maintenance downtime and costs.”

He says work on the C32B enables efficient power utilisation and extended engine performance, even at lower horsepower levels. “We have included specific enhancements that promote greater thermal and mechanical performance as well as higher power density ratings compared with the C32,” he tells Riviera. “Efficient power and extended engine performance are essential for navigating the riverways across the US.

C32B is Caterpillar’s big engine release for 2025 and comes at a time when owners are considering replacing engines, repower programmes and overhauling workboats to keep them operating longer, with lower emissions along North American waterways.

“Most of the fleet will be running on diesel engines for a long time, so we focus our core competences on diesel engines, and we have leveraged developments from one marine segment into another for our big engine release in 2025,” says Mr Sarrat.

On four-stroke, high-speed C32B engines, Caterpillar added block material, alternative valves and a larger crankshaft to get a maximum power of 2,400 hp (1,790 kW) at 1600-1800 rpm. For workboats, power loads of 890-970 kW are required from these engines, so not all the developments, such as sequential turbochargers, were required for the commercial vessels.

However, developments have extended overhaul intervals from 10,000 hours to 15,000 hours. “Internal development has added durability to C32B and helped with load management and fuel burn,” says Mr Sarrat. “These are more efficient engines that work easier to take load demands better.”

These 32-litre, V12 engines electrically control the point of combustion to ensure efficient operations, even with cold-running start up, and can be configured for US Environmental Protection Agency (EPA) Tier 3 compliance and connected to selective catalytic reduction (SCR) units to minimise NOx emissions and EPA Tier 4 compliance.

These engines are available for newbuildings and for repower projects where operators may wish to replace 20–40-year-old engines.

Further developments

Caterpillar will continue to develop other engines, auxiliaries and gensets used in the tug, towage and inland waterways sectors. “For several years, we have upgraded engine platforms for clients, providing more data connectivity, including electronic controls, extending maintenance intervals and using data to optimise maintenance,” says Mr Sarrat. “Some of our platform developments are coming to commercial release as we work on improving existing engine platforms.”

These developments will be ideal for vessels operating along North American waterways, where engines need to deliver power over long periods. “Vessels must continue to deliver the power required for exceptional performance as uptime, dependability, cost-efficiency and safety are paramount,” says Mr Sarrat.

Power solutions that help operators reduce maintenance costs and downtime will enable them to be adaptable as customers’ sustainability goals evolve.

“Extending the time between overhauls creates compelling competitive advantages that allow operators to increase a vessel’s time on the water, enabling operators to win more business. Reducing those maintenance costs supports an operator’s profitability,” Mr Sarrat adds. “Having the flexibility to operate on biofuels can also support profitability as that allows operators to take on jobs with that specification they otherwise wouldn’t be able to support.”

Caterpillar has been running some C32B engines on an inland towboat for the last five years as part of this development project and has seen successful outcomes. “We have the engines hooked up with our full digital suite of telematics connected so we are able to monitor all aspects of vessel operation during this trial period,” says Mr Sarrat. “And what we have seen has been very encouraging. The C32B’s are operating beautifully and have shown improved efficiency and durability over the current C32, and this has allowed us to push the major maintenance overhaul intervals by as much as 50% to date.”

Service agreements

For operators and owners of tugs, towboats, pushboats and other workboats, Caterpillar dealers provide service packages that can include real-time remote monitoring of engines and auxiliaries by experts that understand these products and the demands on vessels, facilitating optimal maintenance.

“Our dealers can use product status reports, connect to the engines and download data on engine operations over their lifetime, whether this is data for the last day, week or month,” says Mr Sarrat. “They can look at average load factors and fuel burn, sample reports and track what is going on inside an engine. Perhaps there will be high levels of metals, which would show there could be issues, such as bearing wear, and indicate where and when maintenance is needed.”

This information is useful to operators as it could prevent issues becoming incidents or cause accidents or equipment failures, which could lead to vessel downtime or operational problems.

Digitalisation has become an important element to these service agreements and can be supported by Caterpillar’s remote monitoring and expertise centre in Houston, Texas.

“Assets can be connected for remote monitoring and we can use predictive analytics to catch issues before they turn into vessel downtime,” says Mr Sarrat. “Customers can use these digital services to fine-tune operations and understand when to do maintenance. We have people on shore monitoring and provide troubleshooting based on condition and performance information.”

Under certain service agreements, a Caterpillar fleet manager will work with owners, operators, port engineers and vessel captains for equipment health management and maintenance programmes and to optimise vessel operations and schedules.

“They would review service history and consider what is coming up in terms of drydockings, to align maintenance, reduce downtime and extend maintenance intervals,” says Mr Sarrat.

“Engine overhauls can be planned for when a vessel goes into drydock for regulatory reasons, so all work gets done at once.”

For large fleets with more than 100 engines and vessels, this could lead to considerable cost savings. “We see significant savings in yearly operations from sharing maintenance information and operational data,” he continues. “Experts are finding issues before they become problems, advising customers to look at performance versus overhaul and finding significant savings of millions of dollars over a year.”

Engine replacement

When it comes to repower projects, there are various drivers for investing in new engines, such as getting another 25 years out of a vessel, moving up to EPA Tier 3 for regulatory purposes, or if there is space for SCRs to Tier 4, or reducing fuel consumption.

“The recipe for repower can go a number of different ways,” says Mr Sarrat. “Regulatory push is getting people to engage in repowers for vessels operating in certain areas where that is required. “Other reasons are efficiency, age and fuel consumption. There are grants for using batteries and alternative fuel solutions, such as methanol engines that are under development. We are getting close with our Cat Marine battery development. There are different offerings for a repower.”

All repowers include replacing or upgrading wheelhouse panels, telematics and controls as well as the engines and auxiliaries. “Our repower projects open doors to optimising maintenance, operations, fuel savings and reducing emissions,” says Mr Sarrat.

Sign up for Riviera’s series of technical and operational webinars and conferences:

- Register to attend by visiting our events page.

- Watch recordings from all of our webinars in the webinar library.

Related to this Story

Events

International Bulk Shipping Conference 2025

Tankers 2030 Conference

Maritime Navigation Innovation Webinar Week

© 2024 Riviera Maritime Media Ltd.