Business Sectors

Events

Contents

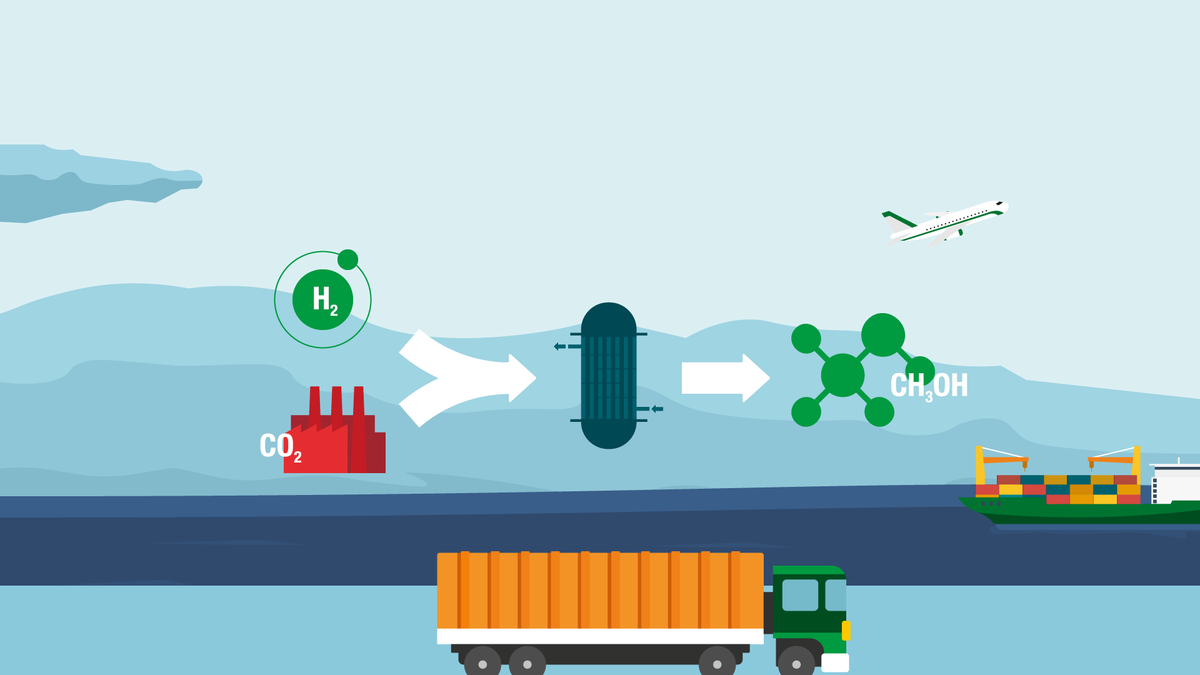

Targeting low-cost, renewable methanol for shipping and transport

Researchers are building new catalyst systems and reactor technologies to reduce energy consumption and lower costs related to synthesising methanol from carbon dioxide (CO2)

The European- and Japanese-funded project is testing three different technologies, which will each require a separate reactor, in a bid to cut the cost of creating renewable methanol from CO2.

The project, called Laurelin, said it is finalising contstruction of the reactors that will each be designed for one of three ’promising’ technologies – microwave, non-thermal plasma induction and magnetic induction – that could optimise the CO2-to-methanol conversion process.

The Laurelin project involves researchers from 10 European and Japanese institutions who have already dedicated a year to designing a more economical way of producing renewable methanol for use in transport.

"The partners will continue to fine-tune these novel reactors in the coming weeks, for example by making them operable at higher pressure," a statement from the Laurelin project said.

"On this basis, the project will test more than 100 samples of new catalyst materials and compare them with conventional thermal hydrogenation. This will help [to] optimis[e] the selectivity and yield of the methanol production."

Renewable methanol is produced by combining hydrogen and CO2 exhaust gases in a process known as thermal hydrogenation. But the conventional thermal hydrogenation process, according to the researchers, has major limitations in cost and energy consumption levels.

"CO2 is generally unreactive and hydrogenation is impossible without the use of a catalyst, a substance added to accelerate the chemical reaction of hydrogen with CO2. Laurelin’s team therefore is developing new catalyst systems perfectly adapted to advanced reactor technologies to reduce energy consumption of the methanol synthesis from CO2, and therefore its cost," the project said.

Laurelin researcher Professor Teruoki Tago from the Tokyo Institute of Technology explained that reducing renewable, or e-methanol, production costs could prove beneficial to its uptake. Laurelin’s statement noted the fuel’s particular potential for aiding in the decarbonisation of the transport sector, which, in Europe, accounts for more than 25% of overall greenhouse gas emissions (GHGs).

According to Laurelin technical co-ordinator Adolfo Benedito Borrás, renewable methanol can cut CO2 by up to 95%, reduce nitrogen oxides by up to 80% and completely eliminate sulphur oxides and particulate matter emissions.

EU’s Horizon funding programme is supporting the project for four years.

Another publicly funded project has said it has developed the first closed-loop e-methanol fuel cell for use in shipping.

UK-headquartered Expleo said its fuel cell system was ’defined’ during a feasibility study into clean power propulsion systems funded by the UK Department for Transport’s Clean Marine Demonstration Competition.

In mid-September 2021 Expleo, along with Bibby Marine and Houlder, received a share of the £20M (US$28M) government fund to finance the feasibility study to fully realise a zero-emissions newbuild and low-emissions retrofit options for mid-to-large size vessels, focusing on Bibby WaveMaster service operation vessels.

Born from the study, Expleo’s e-methanol fuel cell model was applied to the Bibby Wavemaster 1, an offshore windfarm service vessel. The modelling demonstrated the vessel would achieve a 92% reduction in GHGs and could save vessel operators up to £1.4M (US$1.7M) per year, per vessel, resulting in a four-year payback time on capital expenditures to add the retrofitted fuel-cell system to the vessel.

Expleo vice president of marine Jonathan Taylor said, “Our solution uses solid oxide fuel cell (SOFC) technology which, although highly efficient and well suited to use in marine environments, releases a high concentration of CO2. To achieve the desired reduction in GHGs, we partnered the SOFC with a novel carbon capture and storage system, enabling a vessel to use its captured CO2 and green hydrogen to synthesise e-methanol."

According to Expleo, the green hydrogen in the solution could come from dedicated production at offshore windfarms, from surplus electrical energy or be supplied in port to ensure "the closed-loop remains as sustainable as possible”.

Marine Propulsion & Marine Lubricants Webinar Week will be held from 30 August 2022. Register your interest and access more information here

Related to this Story

Events

Maritime Environmental Protection Webinar Week

Cyber & Vessel Security Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.