Business Sectors

Events

Contents

Register to read more articles.

Understanding the potential of methanol as a marine fuel

Methanol has the advantage of a liquid state and ability to repurpose existing infrastructure to include engines and vessels with efficient retrofits, writes ABS director of sustainability strategy, Singapore Panos Koutsourakis

Numerous alternative fuels are under consideration as a means to reduce carbon emissions in shipping. Of these, methanol is one of the two principal options currently available to shipowners, with methanol-powered vessels already in service, further ships under construction and numerous development projects underway.

Available worldwide and used in a variety of applications for many decades, methanol is most commonly produced on a commercial scale from natural gas, but it can also be produced from renewable sources such as biomass or electrolysis powered by renewable power and supported with carbon capture utilisation technology.

Either production pathway, blended into conventional methanol in increasing volumes, could considerably reduce the carbon dioxide (CO2) footprint of its use as fuel. This potential to reduce CO2 output – as well as its ability to provide compliance with IMO 2020 regulations – means that application of methanol is drawing wider interest from owners of oceangoing vessels, shortsea shippers, ferries, cruises and inland waterway vessels.

Properties

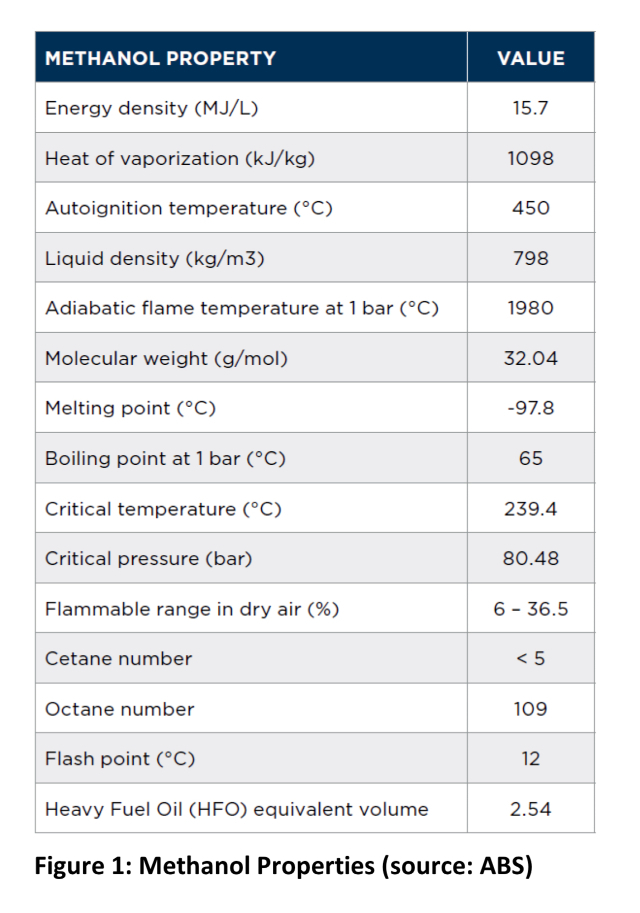

Methanol is a colourless liquid at ambient temperature and pressure with a characteristic pungent odour. It is easier to store and handle than liquefied natural gas (LNG), ammonia and hydrogen fuels and there are also fewer challenges in adopting methanol as marine fuel compared with these alternatives. Its properties are shown in Figure 1.

Methanol has the highest hydrogen-to-carbon ratio of any liquid fuel, a relationship that potentially lowers the CO2 emissions from combustion when compared with conventional fuel oils. When used as the primary fuel, methanol can reduce CO2 emissions by around 10%. However, methanol has the potential to be a carbon-neutral fuel in the future if it is produced renewably through biomass, biogas or renewable electricity.

Methanol’s specific energy of 19,700 kJ/kg is much lower than that of LNG and conventional liquid fuels. For the same energy content, methanol requires about 2.54 times more storage volume than conventional fuels. When comparing methanol to LNG, an overall decrease in the effective volumetric density of LNG is to be accounted for due to packaging factors for cylindrical tanks, insulation and filling factors, boil-off gas, and custody transfer losses.

Methanol has significantly less impact if spilled or leaked into the environment than conventional hydrocarbon fuels. Methanol dissolves readily in water, and only very high concentrations in the environment create lethal conditions or any changing effect on the local marine life. This means that a methanol spill would result in limited damage to the environment except for the release of carbon into the marine ecosystem. Methanol in the ocean is common, produced naturally by phytoplankton, and is readily consumed by bacteria microbes, thus entering and supporting the food chain.

Regulatory approval

The general safety principles of IMO’s IGF and IGC Codes provide the framework for the use of low-flashpoint marine fuels such as methanol. Common safety principles such as fuel tank protective location, double barriers on fuel supply lines, ventilation and gas detection, hazardous area classification, explosion mitigation, etc are equally applicable to all low-flashpoint fuels. However, the specific fuel characteristics may require specific safety features. For methanol, any fuel leaks produce heavier-than-air vapours requiring additional detectors as the fuel is toxic if ingested or inhaled. The fuel characteristics would be considered during the risk assessment analyses.

The adoption in November 2020 of IMO Interim Guidelines for the Safety of Ships Using Methyl/Ethyl Alcohol as Fuel cover considerations for ship design and arrangement, fuel containment system, materials, pipe design, bunkering, fuel supply, power generation, fire safety, explosion prevention, hazard area classification, ventilation, electrical installations, control systems, crew training and operations.

Methanol does not have cryogenic complexity and is a liquid at ambient conditions. Liquid fuels such as methanol are simpler to handle and would be closer to conventional bunker vessels. In addition to methanol being traded and transported in chemical carriers for many years, there is also the experience of the offshore support vessel and platform supply vessel fleets handling methanol for the offshore industry, which can therefore also be reference points for the wider adoption of methanol as a bunker fuel. Methanol is a widely traded commodity with an existing global distribution network that could be leveraged to support marine fuel bunkering.

Vessel applications

The adoption of low carbon and net carbon-neutral fuels for large vessels is more challenging than for smaller ones. Using fuels with low energy content, such as methanol, would require a significant redesign, not least because their fuel tanks would need to be expanded to store enough energy for longer deepsea travel.

However, methanol is more suited to storage in near conventional fuel tanks so can be easier to accommodate in ship designs than other low-flashpoint fuels and also under MSC.1/Circ.1621 5.2.1, may be bounded by the vessel shell plating when located below the lowest possible waterline.

The trade and regulatory landscape of shortsea vessels make them ideal candidates for early adoption of new technologies such as methanol. Fuels such as methanol have strong potential to lower the carbon footprint of shipping, but one of methanol’s challenges is its low energy content and the comparatively lower amount of energy it can store in the tanks of a ship.

That said, compared against other alternate fuels, methanol is relatively efficient at energy storage by volume based on physical tank space. Consequently, shortsea shipping can accommodate the use of fuels with low energy content – such as methanol – that require more frequent bunkering.

Research projects are proceeding on land before testing on board including research projects focusing on engines fuelled by either pure methanol or a methanol mix. Other ongoing research and industrial projects are focusing on scaling up methanol to become available for use in the wider transportation industries.

For use in marine applications, infrastructure such as methanol bunkering facilities and fuel supply systems are to be developed. A partnership between Copenhagen Airports, AP Moller-Maersk, DSV Panalpina, DFDS, SAS, and Ørsted has formed to scale up the production of industrial hydrogen in Denmark, with a vision of producing sustainable fuel for the road, air, and marine transportation networks by 2030.

Near-term potential

The benefits of reduced emissions from burning methanol could be a significant contributor to reducing greenhouse gas emissions from the maritime industry. Existing methanol trade infrastructure can also be an important factor for the cost and availability of methanol over other alternative fuelling options.

One of the main challenges to owners during this fuel transition is to decide on an alternative fuel to prepare for 2050. Early adoption of such fuels depends on the demand and the supply landscape. In the case of methanol, even though its trade is evolved, its many uses and demand for manufacturing may not allow surplus for maritime use without incentives. Due to this widespread use of methanol across the globe, the marine industry can at most claim a fraction of the amount available unless methanol is produced synthetically. However, this option can also incur extra costs.

The use of methanol as a fuel in methanol carriers for propulsion and power generation, along with the development of efficient and feasible dedicated propulsion systems, has already seen an increase in newbuild cargo vessels powered by methanol. If methanol is produced renewably, these tankers could have an even greater potential to reduce lifecycle emissions while concurrently improving the renewable methanol fuel supply chain for other applications.

The use of methanol as a fuel in dual-fuel marine engines may allow for robust operations with various types of alternative fuels in the future. Such applications may use methanol when it is available, with the option to burn other fuels at the convenience of availability and economy.

The advantage of methanol over other gas fuels is its liquid state and ability to repurpose existing infrastructure to include engines and vessels with efficient retrofits. Methanol is significantly easier and more economical to store on board than gas. Retrofitting a vessel’s tanks from conventional fuel oil, ballast, or slop to hold liquid methanol fuel is also easier than installing LNG tanks.

One of the challenges of methanol as an alternative fuel is the lower energy content when compared with conventional fuel oils. However, as methanol is a liquid at ambient temperature and pressure, tanks can be converted with a minor retrofitting to hold larger volumes of methanol required for an equivalent amount of energy. Further methanol applications in marine fuel may only require a scale-up of existing trade, storage, and generation activities. Bunkering facilities and fuel supply systems are to be developed and scaled.

Ongoing research is striving to rapidly scale up methanol availability in terms of infrastructure as well as onboard applications and installations.

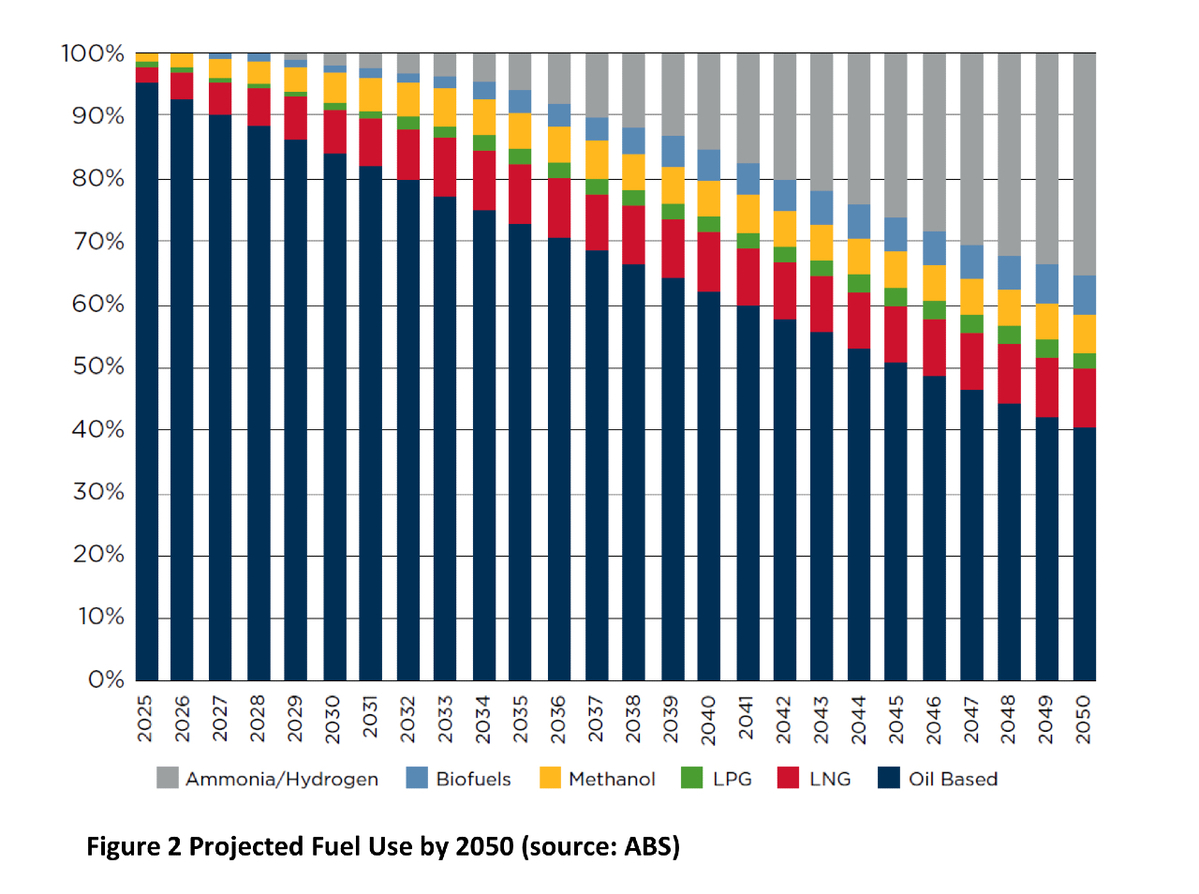

Figure 2 shows the projected marine fuel use to 2050 as the industry strives to meet the GHG emissions-reduction targets mandated by IMO.

Riviera Maritime Media’s Marine Propulsion Webinar Week is being held 26 July 2021 – use this link for more details and to register

Related to this Story

Events

Maritime Environmental Protection Webinar Week

The illusion of safety: what we're getting wrong about crews, tech, and fatigue

Responsible Ship Recycling Forum 2025

© 2024 Riviera Maritime Media Ltd.