Business Sectors

Contents

Register to read more articles.

LM9000, a new liquefaction turbine package for floating LNG

A 70-MW-class aeroderivative driver with a four-stage free power turbine delivers tested full-string performance for single-skid FLNG trains

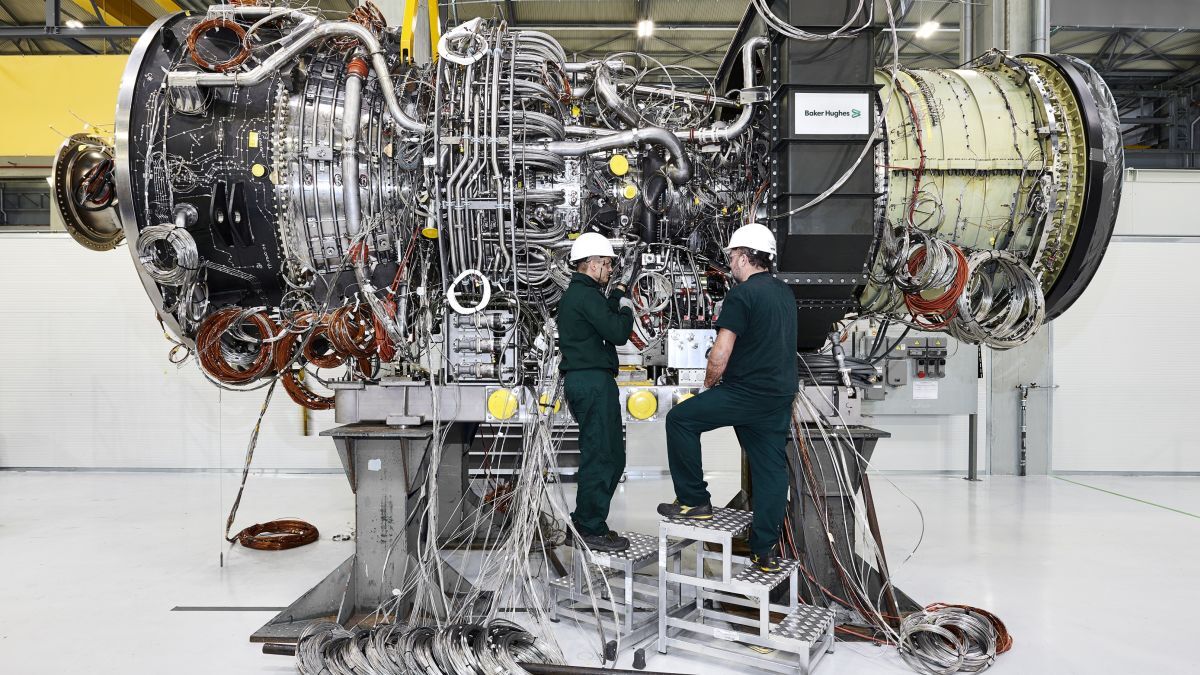

Floating liquefaction depends on a single piece of rotating equipment doing a specific job reliably, day after day: converting fuel energy into shaft power to turn a large mixed-refrigerant compressor without a gearbox, on a compact skid that tolerates pitch and roll. At Gastech 2025, Baker Hughes LNG growth manager Tommaso Rubino presented a 70-plus-MW aeroderivative gas turbine engineered not only but “specifically … for LNG mechanical drive,” delivering high simple-cycle efficiency and a free power turbine speed range that matches the compressor’s operating window while enabling direct coupling.

In LNG usage, a “driver” is the prime mover that supplies mechanical power to a compressor or pump; here, the driver’s role is to spin a seven-impeller, back-to-back single mixed-refrigerant machine from a common baseplate without speed change.

Mr Rubino sets out a technical case grounded in machine architecture, package design and test evidence of a compact, light, efficient mechanical driver built for “long maintenance intervals,” “pressurised start-up,” and a direct shaft-end coupling to the refrigerant compressor.

Mr Rubino frames the floating brief with five words - compact, light, efficient, simple, low-maintenance - and the rest of the engineering follows from those constraints. In simple-cycle configuration, the turbine delivers at least 70 MW of power with a thermal efficiency of at least 44%. The entitlement figures are 73.1 MW and 44.2% respectively, with contract guarantees set below these values. Those numbers define an efficiency and power‑density target that is relevant on a motion‑affected deck with weight, space and auxiliary limits.

The gas path follows an aeroderivative arrangement configured for high specific work: a four‑stage low‑pressure compressor driven by a single‑stage intermediate‑pressure turbine, a nine‑stage high‑pressure compressor driven by a two‑stage high‑pressure turbine, and a four‑stage free power turbine delivering the output. For mechanical drive, the free power turbine covers 2,400–3,780 rpm, matching the compressor operating window for direct coupling; for power generation it enables direct drive of a two‑pole generator at 3,000 or 3,600 rpm. Compressor pressure ratio is higher than 30:1 in simple‑cycle duty and combustion is dry‑low‑emissions.

Those gas‑path choices dictate the mechanical interface on a hull: direct coupling without a gearbox, controlled thrust, and a single‑skid layout that can be serviced without internal lifts.

On a floating deck, mechanical integration centres on direct shaft‑end coupling to the driven machine, supported by ball and roller bearings and an actuated thrust‑balance valve to prevent overload. The driver and compressor sit flange‑to‑flange on a common baseplate just under 24 m in length and approximately 5 m in width, supported by a three‑point gimbal mounting that accepts hull motions without over‑constraint and preserves shaft alignment. Sump pressurisation and evacuation are handled within the enclosure through an integrated regulating valve, removing an external skid.

The near‑shore floating train described uses a single mixed‑refrigerant loop whose core machine is identified as Baker Hughes 2BCL centrifugal compressor model in a two‑phase, back‑to‑back arrangement, with impeller outer diameter of about 1,400 mm and a casing internal diameter near 2,600 mm, making the bundle weight the limiting maintenance case. For readers outside rotating‑equipment practice, the bundle is the removable internal assembly of a barrel compressor that carries the rotor, diaphragms and seals.

Start‑up and transient behaviour are addressed for mixed‑refrigerant duty. The driver supports start‑up with the process loop pressurised and does not require a helper motor. A helper motor is an electric machine used to accelerate a large train through critical speeds during start‑up; eliminating it simplifies the train and reduces auxiliaries. Pressurised start avoids depressurising and re‑pressurising the mixed‑refrigerant inventory, which limits losses and saves time.

The maintenance schedule is expressed in operational terms. A borescope inspection is due at 12,000 hours, a supercore overhaul at 36,000 hours and a complete engine overhaul at 72,000 hours. The enclosure doors are fully hinged and the rails are permanent, allowing lateral extraction with no lifting inside the package; right‑hand extraction is standard and left‑hand extraction is available.

Validation is documented from prototype through factory acceptance to full‑string testing. Prototype development ran on a dedicated test bench at a Baker Hughes’ facility in Massa, Italy, with 3,200 sensors across the gas turbine and auxiliaries to monitor power, efficiency, emissions and mechanical behaviour. Two engines passed factory acceptance tests in Q4 2024 and Q3 2025. The complete compression train underwent a full‑load string test in February 2025 with the on‑skid systems in their final configuration to replicate ambient and process conditions, and the reports record all measured parameters within prescribed limits with a comfortable margin against operational requirements.

Beyond a single-loop SMR train, the LM9000 package can be arranged for dual-loop liquefaction schemes such as C3MR (propane mixed refrigerant) and DMR, with flexible compression layouts. It retains pressurised start and does not require a helper motor. The turbine can also be supplied as a compact power-generation set with a horizontal filter house and axial inlet for direct drive of a two-pole generator at grid frequency, and it can operate at either 3,000 or 3,600 rpm.

The development team, Mr Rubino, LM9000 product leader Tommaso Olivieri and gas turbine product & technologies senior team leader Giovanni Galeandro, appear to have achieved their aim: high simple‑cycle efficiency reduces fuel burn; high power density keeps the envelope within shipyard limits; the four‑stage free power turbine sets the speed flexibility to drive a large mixed‑refrigerant compressor without a gearbox; the thrust‑balance system and bearing choices stabilise direct coupling; rails and hinged portals make a supercore extraction a scheduled task rather than a calendar shock.

As Mr Rubino said in conclusion, “Floating LNG demands a driver that is compact, efficient, and reliable under motion. With the LM9000, we’ve combined best-in-class simple-cycle efficiency with high power density and long maintenance intervals, all in a package designed for direct coupling and pressurised start-up. The result is a turbine that not only meets the operational demands of offshore liquefaction, but does so with lower emissions and greater flexibility.”

Riviera’s LNG Shipping & Terminals Conference will be held in London on 21-22 October 2025. Use this link to register your interest and attend the event.

Related to this Story

Events

Offshore Support Journal Conference, Middle East 2025

Maritime Regulations Webinar Week

© 2024 Riviera Maritime Media Ltd.