Business Sectors

Events

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

Contents

Register to read more articles.

Molten-salt nuclear reactor development begins operational testing phase

Nuclear use for vessels took another step towards commercial reality this week with the beginning of pumped-salt operations in the integrated effects test (IET) - part of the development of molten salt reactor (MSR) technology for maritime applications

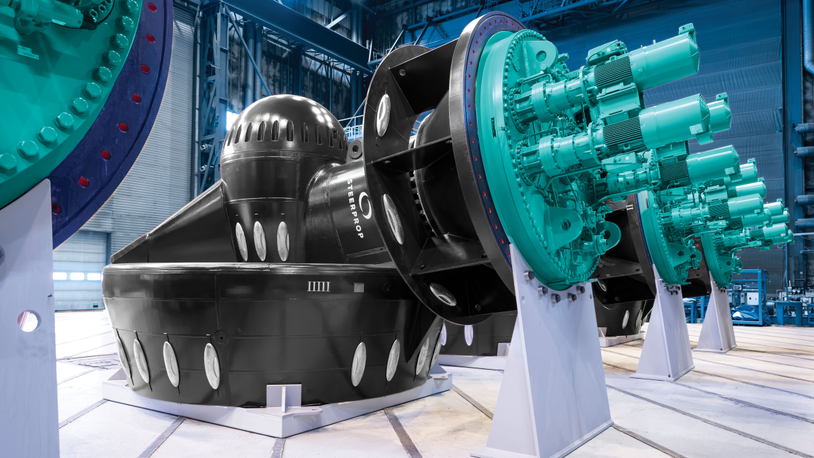

The project brings together American gas and electric utility firm Southern Company; Core Power, a startup that focuses on nuclear power for maritime applications; and TerraPower, a company developing a nuclear reactor.

A team previously completed mechanical, electrical and controls verification and commissioned all systems at an IET facility installed at TerraPower’s laboratory in Everett, Washington.

A molten salt reactor is a nuclear reactor that uses a liquid fuel instead of solid fuel like most conventional reactors. The fuel-salt in an MSR contains the uranium fuel which keeps the fuel-salt liquid at high temperature.

The liquid state means the fuel produces both the heat and the coolant which transports the heat to the power conversion system that makes electric power. Since the fuel and coolant is combined into one and the fuel is always locked into the coolant, Core Power claims this means the reactor cannot melt down.

Chloride salt has now been loaded into the primary coolant salt loops and pumped-salt operations have begun, marking a new phase in TerraPower’s molten chloride fast reactor (MCFR) technology.

The company believes MSRs can be mass manufactured as small modular machines too, which has the potential to transform shipping.

Pumped-salt operations marks the start of a multi-month test campaign which will provide data and know-how for the MCFR programme.

Core Power chief executive Mikal Bøe said the IET will allow the company to collect the crucial last-mile data need to design and build the MCFR, and “takes the team one step closer to a genuinely unique way to do new nuclear that is appropriate for the commercial marine environment.”

The project was initiated by Southern Company and TerraPower under the US Department of Energy Advanced Reactor Concepts award, a multiyear effort to promote the design, construction and operation of Generation-IV nuclear reactors.

In addition to the listed partners, other participants include the Electric Power Research Institute, Idaho National Laboratory, Oak Ridge National Laboratory and Vanderbilt University.

The IET will inform the design, licensing and operation of an approximately 180-MW MCFR demonstration planned for the early 2030s.

The idea of combining the fuel and coolant in the reaction using molten salt fuels was first conceived in the 1940s, with a functional MSR test running in 1954 at Oak Ridge National Laboratory in Tennessee, USA.

Like so many breakthroughs, it had its origins in military applications. The original plan was an aircraft reactor experiment with the idea of powering war planes that could stay in the air for very long periods of time. The reactor ran for96 MW-hours but the introduction of inter-continental ballistic missiles ended the project. In 1962, work began on the construction of an experimental test reactor called the molten salt reactor experiment and a reactor was started within four years, ending in 1969 due to funding cuts.

"It’s exciting to see each new landmark in the integrated effects test, as it helps our nation rebuild lost molten salt reactor knowledge,” said Southern Company senior vice president for research and development, Mark S Berry.

Mr Bøe added, “New nuclear for maritime is the only solution that can take the ocean transport industry to actual zero. It’s the end game of our energy transition and with solid progress being made in building a new nuclear technology that actually works for shipping, we see the momentum continuing to build.”

Riviera Maritime Media’s Maritime Decarbonization Conference, Americas will be held 12-13 December 2023 in Houston, USA. Use this link for further information and to register your interest

Related to this Story

Events

Maritime Regulations Webinar Week

Floating energy: successfully unlocking stranded gas using FLNGs and FSRUs

© 2024 Riviera Maritime Media Ltd.