Business Sectors

Contents

Register to read more articles.

High-speed engine developers zero in on methanol and biofuels

SMM 2022 offered enginebuilders the opportunity to display new prime movers and gensets capable of burning methanol and biofuel

Stands at the recent SMM 2022 in Hamburg bristled with the newest engine technology for low- and zero-carbon fuels, offering attendees a glimpse of the future of high-speed propulsion.

Based on the newly developed high-speed engine technology available at the German international maritime trade fair, methanol and biofuel have gained favour in the tug and towboat, ferry, yacht and inland waterway sectors.

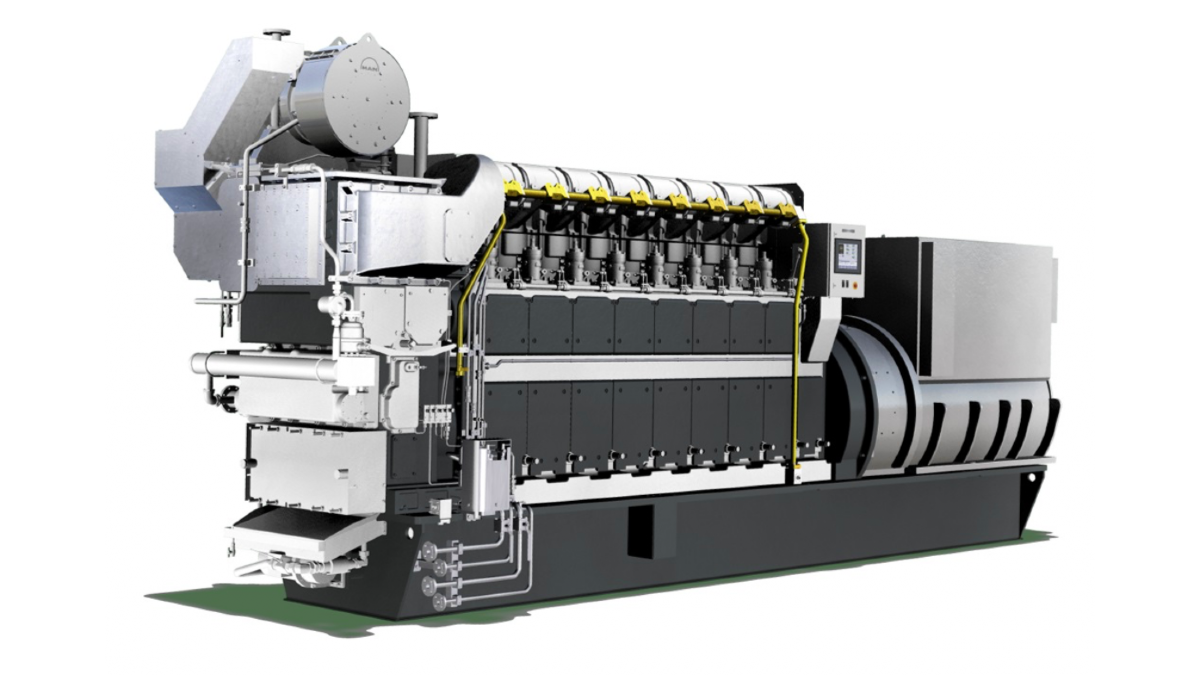

This was apparent from the offerings highlighted at the stand of Rolls-Royce Power Systems, where company global marine vice president Denise Kurtulus said initial development of methanol-burning engines would be based on its well-proven mtu series 4000 platform. These units would be commercially available in 2026.

Being developed with funding from Germany’s Federal Ministry of Economics and Climate Protection under the MeOHmare project, the mtu methanol engine will operate on the Otto-cycle principle, mainly used in the brand’s gas engines. Rolls-Royce Power Systems has extensive experience with liquid fuel, primarily through its diesel engines. However, methanol (CH4O) differs fundamentally from diesel in many chemical and physical parameters; these range from specific energy content, density, evaporation properties and ignition energy to viscosity and lubrication behaviour.

“The changes required in the methanol engine, compared with existing engines, are significant”

“The changes required in the methanol engine, compared with existing engines, are significant," explained Mathias Müller, technical project manager for development projects at Rolls-Royce’s Power Systems business unit. “This applies in particular to many subsystems, from injection and turbocharging to the entire cylinder power unit, the lubrication circuits and the engine control system.”

Ticking off methanol’s attractiveness as an alternative fuel, Mr Müller, said: “Green methanol, so-called e-methanol, has the advantages of a liquid, energy-dense fuel for mobile applications. In addition, we expect its production to be economically competitive and advantageous over other e-fuels in the future.”

These, among other benefits, provide e-methanol with a leg up on pure electric propulsion and hydrogen-fuelled energy converters, as well as over solutions using other e-fuels. Methanol’s liquid state makes it easy to store and refuel at ambient temperatures. In addition to reduced complexity, the more attractive investment costs are another advantage of the methanol tank system.

While LNG has a higher volumetric density than methanol, for example, it requires more complex and costly engine technology, fueling systems and cryogenic storage. However, methanol requires 2.54 times more storage volume than conventional fuels.

Burning conventional methanol will reduce CO2 emissions by about 10%, SOx by 99%, NOx by 60% and particulate matter by 95%. Current methanol demand is about 98M tonnes, half of which is used for the production of formaldehyde or conversion to olefins. Demand is expected to increase five-fold to 500M tonnes by 2050, with biomethanol and e-methanol accounting for about 80% of production, according to IRENA.

Biodiesel approved

Following field tests conducted since 2019, using hydrogenate vegetable oil (HVO) renewable diesel in mtu engines, Rolls-Royce has approved its Series 2000 and Series 4000 mtu marine engines for EN15940 synthetic diesel fuels from the beginning of 2023. These fuels include the sustainable fuels BtL (Biomass to Liquid), HVO (Hydrotreated Vegetable Oil/renewable diesel) and PtL (Power to Liquid) such as e-diesel.

“Since 2019, we have been successfully testing the use of HVO with mtu engines in six ferries in our fleet,” said Jim Swindler, general manager for Golden Gate Ferry, based in San Francisco. Over 41,000 operating hours were accumulated during the tests. Four other shipping companies in the US are testing the use of HVO in their mtu engines. HVO is a drop-in fuel, which means that the previous diesel system infrastructure can be used unchanged, and no engine hardware or software modifications are required.

Rolls-Royce said using HVO can result in a reduction in particulate emissions of up to 80%, nitrogen oxide emissions by an average of 8%, and (depending on the manufacturing process and feedstock) CO2 emissions by up to 90% compared to fossil diesel.

“We expect its production to be economically competitive and advantageous over other e-fuels”

At SMM, Cummins displayed a full range of information on its high-speed engines, including its in-line, four-stroke X15 diesel engine. Speaking at Riviera Maritime Media’s Power plant and gensets: how new fuels are changing engine design webinar, held prior to SMM 2022 in late August, Cummins director of business development and tug segment leader Eddie Brown said: “HVO is approved for several platforms and a range of products. We have started this journey and have approved HVO on some engines, while still working on others.” Mr Brown expects HVO to be approved for most engines in 2023.

Mr Brown said methanol will be effective on tugs, workboats and other port and offshore service vessels. “It helps solve the green problem,” he said. “Methanol’s energy density is not as good as diesel but is better than hydrogen and ammonia, and it does not need high-pressure storage tanks.”

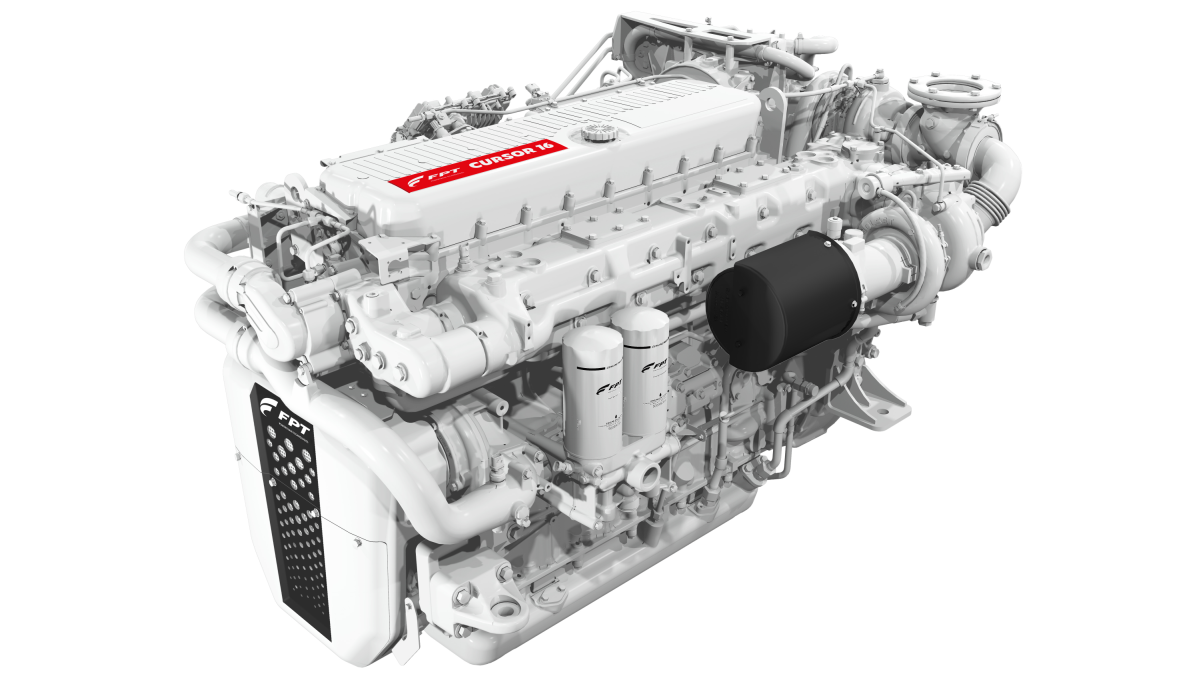

Keel-cooled engine

Also on hand at the German trade fair was FPT Industrial, part of IVECO, which displayed several high-speed main and auxiliary engines, including its new keel-cooled C16 1000, which is suitable for towboat and tugs operating in muddy, shallow inland waters. Keel cooling can efficiently transfer heat between the coolant and the water, without the need to circulate salt water in the engine.

The major benefits include protection of the engine from seawater corrosion, avoidance of continuous seawater filter obstruction, and preventing frequent damage to the seawater impeller.

The 16-liter C16 1000 can be used not only for displacement hulls, but also for high-performance fishing boats. The six-cylinder, keel-cooled engine has a maximum power of 599 kW at 2,300 rpm and meets IMO Tier II and EPA Tier 3 regulations.

All FPT Industrial’s common rail marine engines, including keel-cooled configurations, can be fueled by HVO with “no compromise on performance,” said FPT Industrial, noting reductions in CO2 emissions of up to 90% can be achieved, depending on the feedstock used in the HVO production.

Related to this Story

Events

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

CO2 Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.