Business Sectors

Contents

Register to read more articles.

Zero-emissions ferries: the move to full electric and hydrogen

DFDS eyes green hydrogen, green methanol and green ammonia; the business case for E-Ferry Ellen

Increasing numbers of ferries will go fully electric, while green hydrogen, methanol and ammonia are all fuel options – but the high prices for green technology need to come down.

These were some of the main conclusions of the Ferry sector: paving the way towards zero emissions webinar on 28 April 2021, part of Riviera Maritime Media’s Passenger Ship Webinar week.

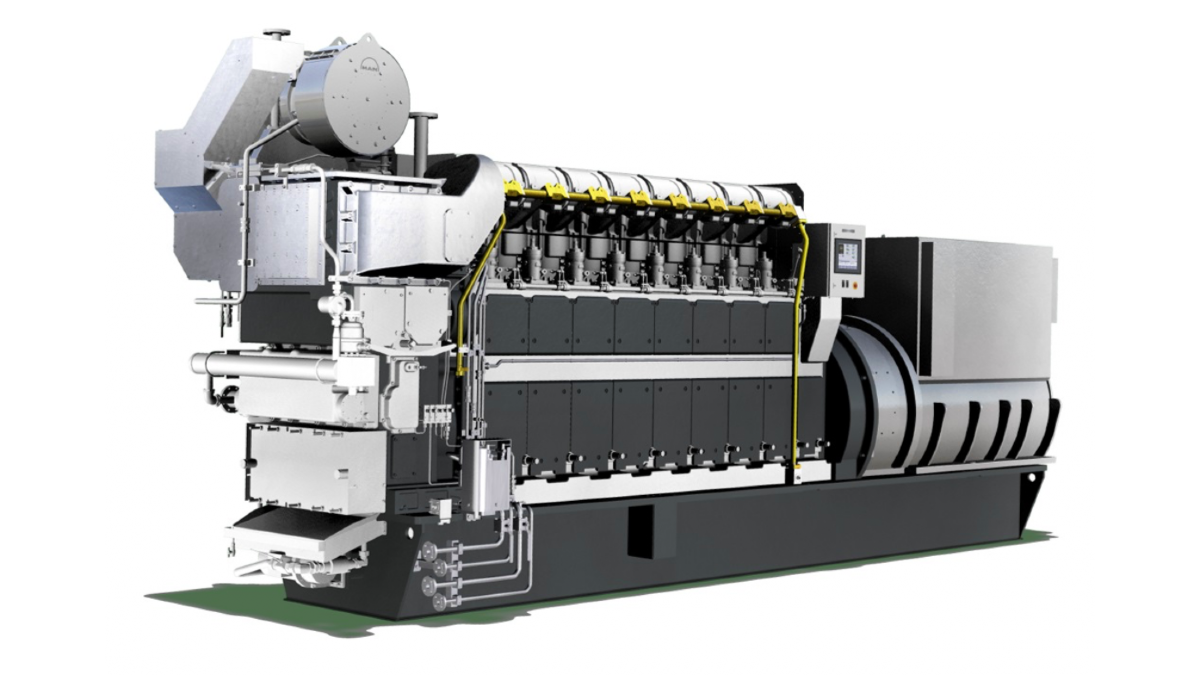

Sponsored by Wärtsilä, the panel consisted of Aeroe EnergyLab media and information manager Halfdan Abrahamsen, DFDS director, innovation lead, technology and innovation Jakob Steffensen and Wärtsilä Norway senior sales manager, integrated systems and solutions EPMS, Per Vidar Johannesen.

Mr Johannesen highlighted what to consider when looking at electric propulsion for a ferry. “Ferries come in different sizes, they have different operational profiles, different routes and length, and different infrastructure at the dock.” Aspects to consider, he said, are the sailing times and lengths, time in dock, power consumption, number of transit times per day and year, and whether it is designed for several routes or one route.

In terms of infrastructure, Mr Johannesen singled out: what charging power is available? Is it on one or both sides? What is the charging power cost and charging time available?

He said, “A double-ended ferry with a sailing time of below 30 minutes, with charging available is able to go fully electric. But if the sailing time is over 60 minutes, or there is no charging available, then engines burning a green fuel mix combined with batteries, fuel cells, or hydrogen can be considered.”

But he said for a bigger ferry such as a ropax with a sailing time above one hour and a high power demand, fully electric is not possible at this stage. It could however have green operations in port and hybrid propulsion for sailing.

Speaking about trends, he said, “The trends we see are requirements from the government to reduce the carbon footprint. We can make longer routes and bigger ferries fully electric; shore charging power is more available, and engines are developed for a fuel mix that is green.”

In terms of cost, he said a fully electric or a hybrid vessel will normally have a higher capex than a normal ferry, and while the opex might be lower, this is based on electricity costs and available fuel prices. “Government requirements or financial support is normally required for a reasonable payback time for ferries,” said Mr Johannesen.

Meanwhile, Mr Abrahamsen spoke about Aeroe muncipality’s experience with pioneering E-ferry Ellen. “We have demonstrated that we are fully electric on a regional route,” he said. The ship uses green energy from the island’s wind turbines to sail emissions free.

Ellen: ‘breaking barriers’

“On the island there are rather ambitious emissions goals and that meant we had to do something about our ferries. That is why we took a chance and developed a ferry where we had to break some barriers, not least on distance, but it worked and we did it,” he said.

He singled out the importance of the ferry’s ramp-based charger, as when the ramp is lowered on deck a very solid connection is achieved. “That is crucial as our experience with earlier projects shows one of the weak points is if you can’t keep connected then you get delays or cancellations. I recommend a solution where you get a firm connection even if it is windy or there are a lot of waves in port,” said Mr Abrahamsen.

He elaborated on another important point. “We haven’t reduced the service level by going fully electric by having more energy than needed to sail.” The ferry has surplus energy, as for the first three trips it spot-charges for 10 minutes back at the home port and in the lunch break, there is 30 to 45 minutes to top up the batteries once more. The ferry is also charged overnight. All this means the ferry can sail at least seven times a day.

Highlighting the business case for such a ferry, Mr Abrahamsen said the solution means 2,520 tonnes of CO2 and half a tonne of particles are saved a year. “For a new Ellen, the operator will start saving costs after four to eight years depending on if there is shore power. The business case gets better and better as battery prices are continually falling.”

Green hydrogen, methanol and ammonia

Elsewhere, Mr Steffensen revealed DFDS’ long-term climate action plan to become climate neutral. He said, “What it takes is a new fleet. We need to replace the kind of vessels we have today with a new generation of ships that are able to run on much more sustainable fuels.”

The company is looking at three core fuel candidates: green hydrogen, green methanol and green ammonia. “These are very different from the fuels we use today, so we have a lot to learn, and we need to learn it fast to implement the new generation of ships in time,” said Mr Steffensen.

“At DFDS, we have a company culture that works great with open innovation. Our strategy is to do joint projects with equipment manufacturers, fuel-cell manufacturers, universities etc that have the skills we are short of and through this process we learn and get access to people who have the competencies we need.”

He said DFDS used time and resources within the pandemic looking into what a zero-emissions ship looks like and “chasing to make a new generation of the ferry” crossing between Copenhagen and Oslo. The plan is for a 100% fuel cell-powered ship running on green hydrogen, without a combustion engine on board.

Mr Steffensen said, “A lot of the technology we need is actually available shoreside, it has not been [used in marine applications] yet, so it is not like starting from scratch, but still needs to be approved.”

The challenges are that the engineroom equipment is approximately six times as expensive but, Mr Steffensen warned, “that is not worst part of it, what really makes it tough is increased fuel costs. We are estimating fuel costs almost four times as high compared with running on fossil fuels. A ship like this needs a lot of green hydrogen, every second day we would need to refuel it with 44 tonnes of green hydrogen.”

DFDS is involved in two projects where it is focused on making sure the energy it needs is being produced in the areas where the operator trades.

Mr Steffensen said, “The big thing is to get costs down and to do that we need to team up with other sectors where we both need the same kind of sustainable energy carriers.” The operator is teaming up with farmers, as they need a lot of green ammonia to produce green fertiliser and those in the shipping community can use green ammonia for ships. DFDS is also teaming up with aviation and road logistics to produce green hydrogen that can be converted into methanol.

Mr Steffensen said, “The biggest obstacle to going green is the price gap between sustainable fuels and the fuels we use today. But it is very inspiring to see how the future generation of ships can become very simple. Today there are a lot of moving parts, but going forward the engineroom could become very simple with just a battery, fuel cell and electrical motor to make the propeller turn.”

Key conclusions

Mr Johannesen said it was important for supplier and ferry operator to work together on the route, infrastructure and charging when it came to designing a green ferry.

Mr Abrahamsen said, “The near future will be full of innovation and that is exciting from a technological standpoint, I feel the will is there to embrace new technologies and move forward to an emissions-free future.” He singled out energy storage as being a main factor. “We hope that when batteries are not up to sailing anymore, maybe we can use them as storage banks on shore.”

Mr Steffensen said, “The main takeaway for me is that nobody seems to be questioning if we need to go green anymore… we as an industry are agreeing on what the future needs to look like for us to go green and our responsibility is to be vocal about how we see our transition pathways so big investors can build hydrogen and ammonia factories and invest in bunker barges. It makes me proud that people are not questioning this.”

Poll results

The movement towards zero emissions among ferry operators is fast gaining momentum, our audience webinar polls reveal.

Asked, Do you have projects where you evaluate alternative green fuel? A huge 80% said yes.

Asked, Do you have projects where you evaluate fully electric ferries? The split was almost equal with 49% saying yes and 51% saying no.

But there are some challenges to battery power. Some 84% agreed that a lack of available shore-charging capacity is a barrier to switching to fully electric ferries, with just 16% saying no.

Asked, What do you see as the biggest internal obstacle within your company for zero-emissions products and services? The majority (28%) agreed with the statement: The transition is very costly, and we are not able to prioritise this right now. 23% said, We are still in the process of identifying which role we must play in a zero-emissions future; 19% said the technologies needed are not available. 14% said the business case is unattractive and 9% said, We need employees with new skills, and these are very difficult to attract. There is an insufficient top management focus, said 7%.

Use this link to view this webinar and others in Riviera’s webinar library.

To view details of upcoming Riviera webinars and virtual conferences use this link to the events page

Ferry sector: paving the way towards zero emissions webinar panel, from left to right: Aeroe EnergyLab (Municipality of Aeroe) media and information manager Halfdan Abrahamsen, DFDS director, innovation lead, technology and innovation Jakob Steffensen and Wärtsilä Norway senior sales manager, integrated systems and solutions EPMS Per Vidar Johannesen

Related to this Story

Events

Reefer container market outlook: Trade disruption, demand shifts & the role of technology

Asia Maritime & Offshore Webinar Week 2025

Marine Lubricants Webinar Week 2025

CO2 Shipping & Terminals Conference 2025

© 2024 Riviera Maritime Media Ltd.